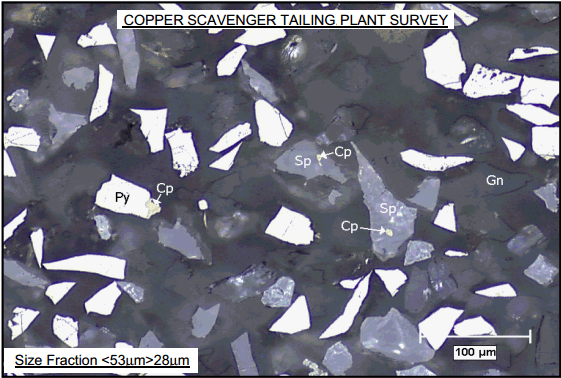

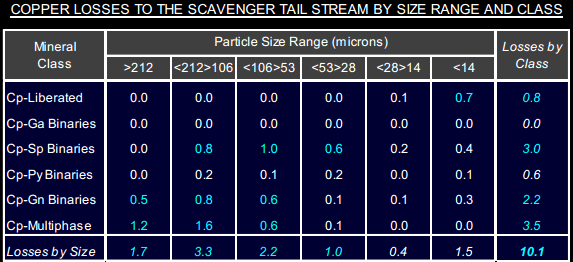

In this example, the losses of chalcopyrite to the copper scavenger tail is equivalent to about 10 percent of the copper in the ore.

Losses of liberated chalcopyrite are minimal accounting for less than 1% of the copper in the feed. Most of these losses occurred as grains sized smaller than 14µm in equivalent diameter.

About 55% of the copper losses to the scavenger tail are present as tiny adhesions, or inclusions of chalcopyrite in non-sulphide gangue or as complex multiphase structures. These composite classes typically occur in the coarser size ranges, and contain about 5% by weight chalcopyrite or about 3% by target area. The probability of improving the recovery of these classes of binary and multi-phase structures, without activating or entraining other non-desirable minerals, is considered remote.

About 30% of the copper lost to the scavenger tail occurs as chalcopyrite-sphalerite binaries. These binaries comprise about 10% by weight chalcopyrite. Improved recovery of this class of binary composite would be deleterious to the operation of the copper circuit. Potentially contaminating the copper cleaner circuit with unliberated sphalerite.

- Flotation Process Development and Assessment

- Mineral Composition and Fragmentation

- Evaluating Copper Rougher-Scavenger Flotation Circuit Performance

- Measure and Evaluate Flotation Scavenger and Cleaner Tail Losses

- Effect of Regrinding

- Evaluating Copper Flotation Cleaner Circuit Grade/Recovery Results

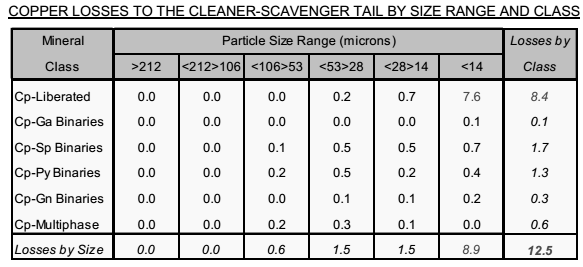

Copper Losses to the Cleaner Circuit Tails

The cleaner-scavenger tail stream accounts for more than half of all copper lost from the entire copper circuit.

The above table has details of the chalcopyrite losses by particle size range and by class of mineralogical association.

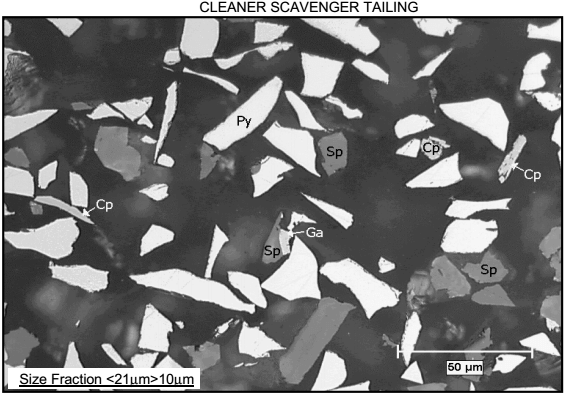

Above are some examples of locked and liberated mineral particles found in the cleaner-scavenger tail stream.

The following conclusions can be drawn from the examination of the copper cleaner tailing:

About two thirds of the chalcopyrite losses are attributable to the rejection of liberated grains of chalcopyrite to the cleaner circuit tailing. These liberated copper sulphide grains are sized finer than 14µm in equivalent diameter. Although these fine chalcopyrite grains are relatively difficult to capture, in a practical flotation circuit, they should be considered reasonable targets to help improve overall copper recovery to the concentrate.

Other losses to the cleaner-scavenger tailing include binary particles of chalcopyrite with sphalerite and pyrite. The majority of the losses of these two classes of chalcocite bearing particles are relatively finely sized:

These binary particles are considered poor targets for improving overall copper recovery in the cleaner circuit.