Table of Contents

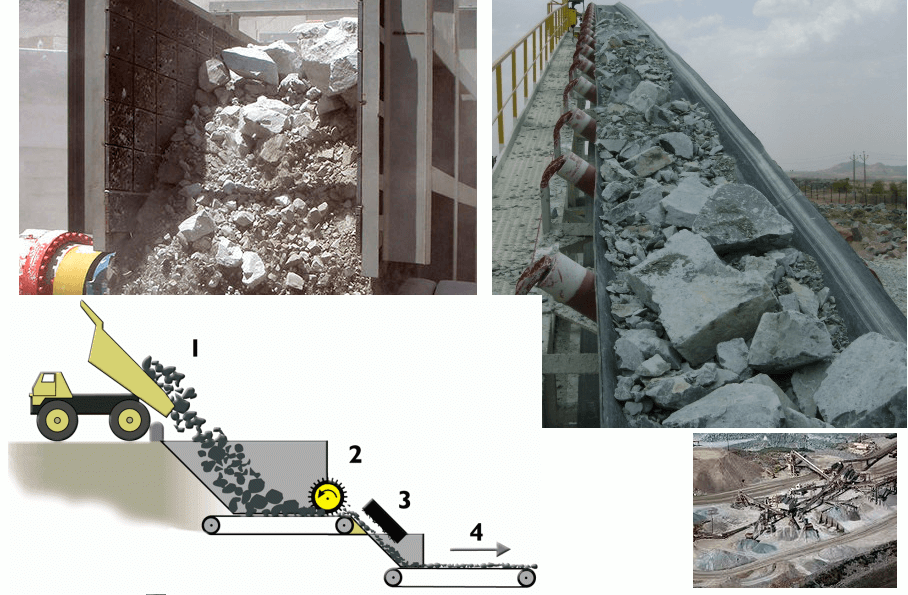

Methods used in Crushing & Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers.

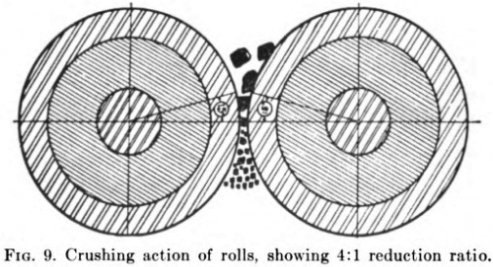

Crushing is done underground at a few large mines. In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the first breaking. There is a wide choice of these machines. Wearing parts are of special steel, especially hard-faced at the point of greatest abrasion. For secondary and tertiary crushing, gyratories and cone crushers are used, the latter particularly for final reduction, but this can also be done by rolls, which give a uniform product.

Interposed in a large crushing plant should be grizzlies, screens, feeders for crushers, magnets for picking up loose iron and steel, and devices for weighing the ore.

The problem of ore comminution involves equipment that will handle the large pieces of rock resulting from mining operations and turn out a product of the relatively small particle size necessary for successful gold extraction. This size reduction is almost always carried out in two successive steps; coarse crushing (dry) followed by fine grinding (wet). Dry crushing is seldom carried below about ½-in. particle size, experience having shown that the breaking of material beyond this point is more satisfactorily accomplished by wet methods. On the other hand, there is a trend today toward feeding considerably coarser material to rod mills which function to some extent as wet rolls.

An efficient crushing and screening plant almost invariably employs the principle of stage reduction, with grizzlies, trommels, shaking or vibrating screens interspersed between stages to separate out the material that is already fine enough to by-pass the next step. The grizzly—stationary, rotary, or reciprocating—is suitable for the first stage, but thereafter the trommel or screen is more positive in its separation. Few trommels are used, except those on dredges and in sand and gravel plants.

Where to Position the Crusher

Coarse crushing or breaking is the primary mechanical step in ore reduction. It is frequently done underground in large plants such as the McIntyre and Hollinger mines. Where sorting is done, it is usually at the shaft mouth, although central plants may be used.

As regards primary crushing machines, the choice is limited to two types—the jaw crusher and the gyratory.

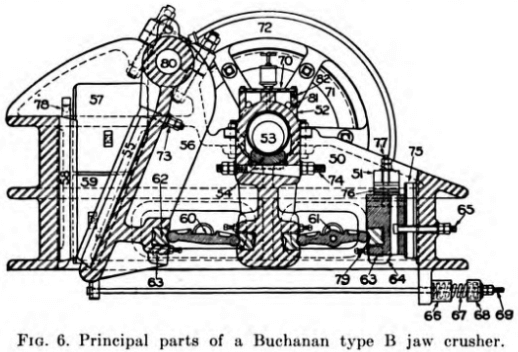

The jaw crusher is, of course, a reciprocating-action machine, crushing rock by direct pressure between a fixed plate and a swinging jaw.

The gyratory crusher, on the other hand, consists essentially of a circular shell with inner sides inclining toward a central orifice. A central shaft passes vertically through this opening and is hung centrally from a spider, which spans the opening at the top. This shaft is eccentrically moved at the bottom and is equipped with a conical crushing head, which operates between the inclined sides of the shell, crushing rock between the head and shell. The crushing operation in this machine is continuous and rapid. It is able to clear itself when completely buried in its feed.

In selecting the proper type of primary crusher a balance must be established on the basis of the largest size of rock to be crushed and the total quantity of material to be handled in a unit of time. It is also to be borne in mind that the product of the gyratory is much more uniform in size than that of the jaw crusher.

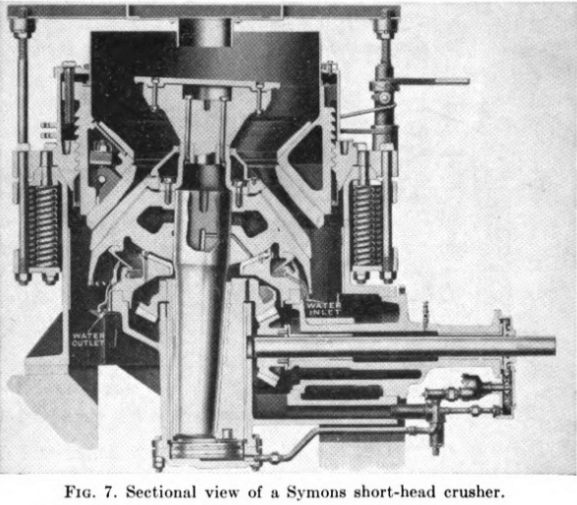

Cone crushers are a modification of the gyratory type in that the conical crushing head is eccentrically mounted on a vertical-drive shaft that is supported entirely from below. The top crushing mantle is spring loaded to take care of tramp iron and overloads, and the clearance between the crushing faces is adjustable by rotation of the top assembly which is attached by a heavy threaded connection to the frame of the machine. The Nordberg Manufacturing Co, made the Symons standard cone crusher for normal-size reduction and the Symons short-head crusher for fine crushing operations.

Older plants operate jaw crushers for crushing ahead of stamp mills, but in the newer ones, jaw crushers break the ore prior to sorting, and gyratories are used for the finer reduction ahead of tube or ball mills. Cone crushers are used in a few plants, and probably more will be installed.

While jaw and gyratory crushers compete for primary crushing, gyratory and cone crushers share the secondary field.

How to Feed a Crusher

There are roughly four periods in the normal cycle of coarse crushing where feeders are not employed:

- The breaker receives a large charge of ore,

- operates under choke feed with the power at a maximum,

- gradually discharges the crushed ore, and

- runs empty.

This is not the most economical method yet is the practice in many crushing stations. Some method of feeding a crusher regularly is preferable. This may be done by means of a feeder or gate to the bin above the machine or by a heavy chain, a pan feeder, a shaking grizzly, or an apron feeder, which occupy little head space. The objective is to ensure a regular feed to keep the crusher steadily occupied and thus flatten the power curve. Figure 8 shows an apron feeder-jaw crusher arrangement. Cone crushers and rolls, particularly, may be fed by belts or drum feeders; cone crushers sometimes are fed from chutes.

A typical Ross chain feeder consists of six lengths weighing 5½ tons. The feeder is driven by a 5-hp. motor through a bronze worm reducer, with a sprocket chain-gear and pinion arrangement. This gives a speed of 19 r.p.m. and a capacity of 175 tons an hour.

Primary Crushing

Crushing Underground

This practice has been adopted on a number of properties, particularly in Canada. At the Kerr-Addison and Hollinger properties the ore is crushed underground in jaw crushers to 4- to 6-in. pieces before being hoisted to the surface. The same scheme is followed at the Pamour-Porcupine mines and at the McIntyre Porcupine, where the underground crushers make about a minus 7-in. product.

Crushing on Surface

At the Golden Cycle custom plant, Colorado Springs, treating Cripple Creek and other ores, a 5½-ft. Symons cone crusher is fed with ore of 3½ to 4 in. maximum size which has passed over a vibrating screen having 0.18- by 0.9-in. openings. The Symons produces 100 tons an hour of ½-in. material for further comminution.

At the Premier mill, British Columbia, the mine-run ore is dumped on a grizzly of 80-lb. rails, spaced at 12 in. A Stephens-Adamson apron feeder delivers the grizzly oversize to an 18- by 30-in. jaw crusher set at 3 in.

At the Ross shaft of the Homestake mine, the primary crushing is done by two Allis-Chalmers size 8 gyratories. They are driven by 70-hp. motors and reduce the ore to 4½ in.

Secondary Crushing

Secondary crushing may be done by jaw or gyratory breakers or by cone crushers.

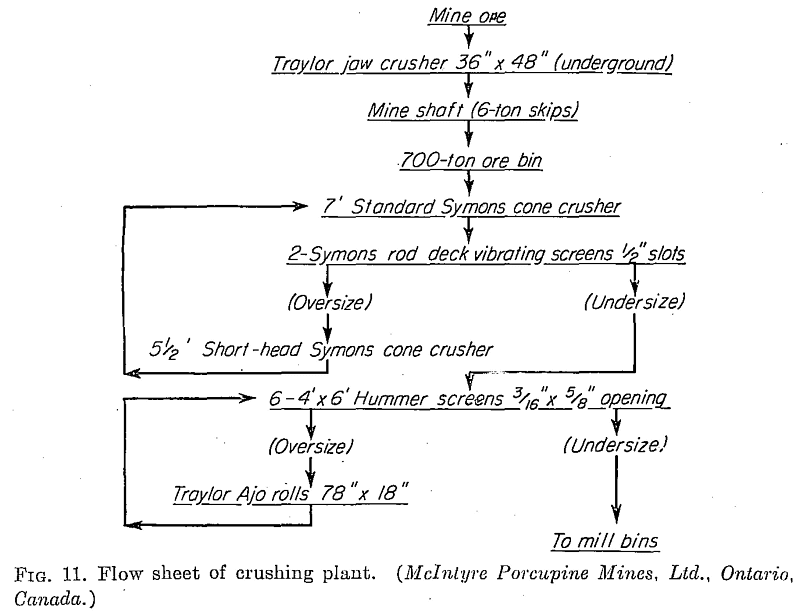

In the surface plant at the Mclntyre-Porcupine a 7-ft. Symons cone crusher (see Fig. 11) set at 7/16 in., crushes material from the mine breaker. A 200-hp. motor with V-belt connection drives the crusher.

Second-stage crushing at Loreto, Pachuca, Mexico, is as follows: 4-in. ore from the first crusher, combined with the undersize of a grizzly above it, is passed over two Symons 4- by 8-ft. rod deck screens, the oversize of which is fed to two Symons 5½-ft. standard secondary crushers, making a ¾-in. product. Each is driven by a 225-hp. motor and V belt and consumes 172 hp.

At the Premier mine, British Columbia, 3-in. ore from the primary breaker passes over a Niagara screen with 1-in. openings. The oversize is fed direct to a size 6 McCully crusher set at 1 in.

At the Ross shaft of the Homestake mine, the 4½-in. ore from the primary breakers passes over a grizzly to two 7-ft. Symons cone crushers, set at 1¾ in. in open circuit.

Tertiary Crushing

The third step in crushing, or tertiary reduction, depends upon what is required. Two-inch or smaller pieces from the secondary crushers may be fed direct to stamps, rod mills, or ball mills, but it is more usual to use a third dry crusher to reduce the ore to ½- or 5/8-in. size before wet crushing, particularly in the case of ball milling. For such work the Symons short- head machine is well suited, just as the standard machine is for coarser reduction.

Common Crushing Plant Design & Layout

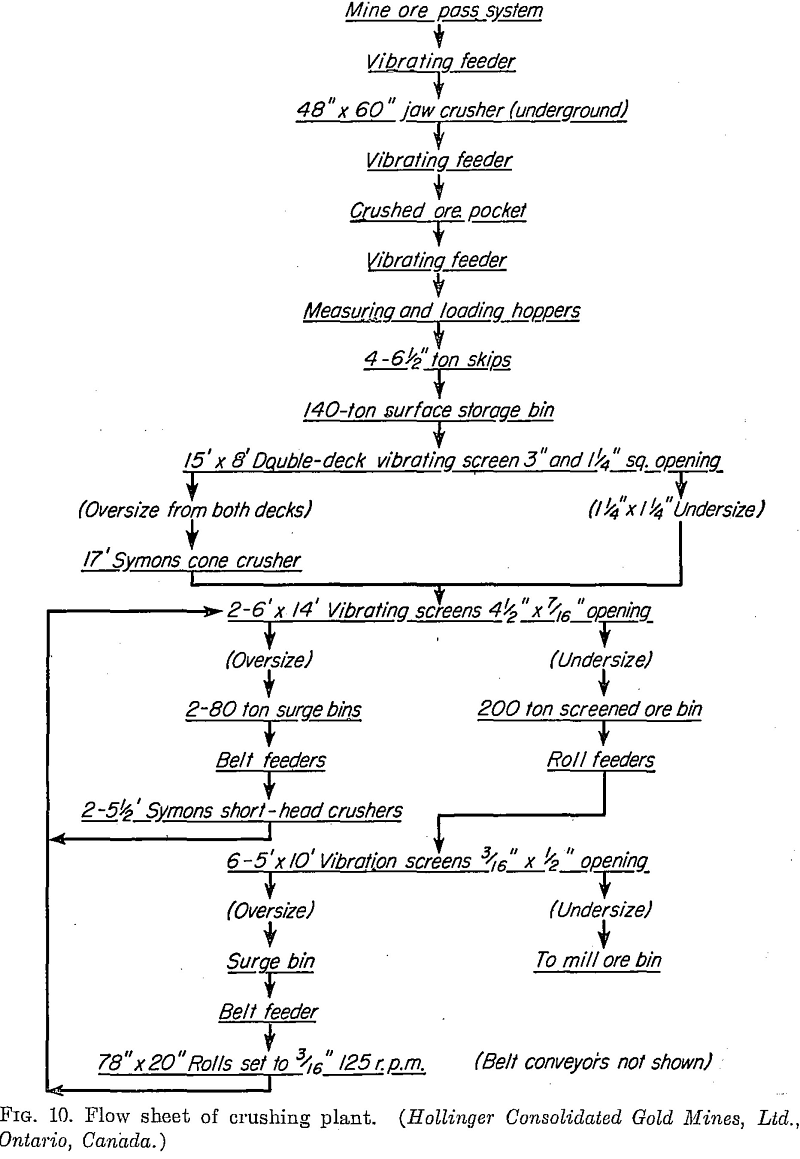

The Hollinger crushing plant is one of the largest and most up-to-date plants in Canada. Of steel and concrete construction throughout, high headroom is provided so that, with the exception of a single lift through shuttle conveyors to Nos. 2 and 3 screens, there is gravity flow to all machines (see Fig. 10).

The ore is crushed underground to minus 6 in. and hoisted to 140-ton surface bins. From there it is fed to a 7-ft. Symons cone crusher after passing over a double-deck screen that removes 1¼-in. undersize from the crusher feed. The product of this crusher plus the product of all other crushing units in the plant is then conveyed to the secondary screens which are situated at the top of the building. These 6- by 14-ft. vibrating screens separate out the 4½- by 7/16-in. undersize for storage in a 200-ton bin, from which point it is fed by roll feeders into six 5- by 10-ft. tertiary screens that make a final undersize (3/16 by ½ in.) for transfer to the mill bin. The oversize from the secondary screens is crushed in a 5½-ft. Symons short- head crusher set at 3/8 in., and the oversize from the tertiary screens crushed in a set of 78- by 20-in. rolls set at 3/16 in- Both machines are closed-circuited with the secondary screen, and in this respect the flow sheet differs from the four-stage crushing at McIntyre Porcupine, where each crusher is separately closed-circuited with its respective screen.

The crushing plant has a maximum capacity of 440 tons per hour and carries a circulating load of about 2:1 over the final screens and 1200 to 1400 tons per hour over the secondary screens. The plant is completely equipped for dust control with some 40,000 cu. ft. per min. of air drawn through the cyclones, and 60,000 cu. ft. per min. of air through roof vents.

On account of the large volume of air being displaced, it is quite impossible to attempt to heat this building in the winter, and there is only a difference of a few degrees between inside and outside temperatures. Heated cubicles are provided for the operators.

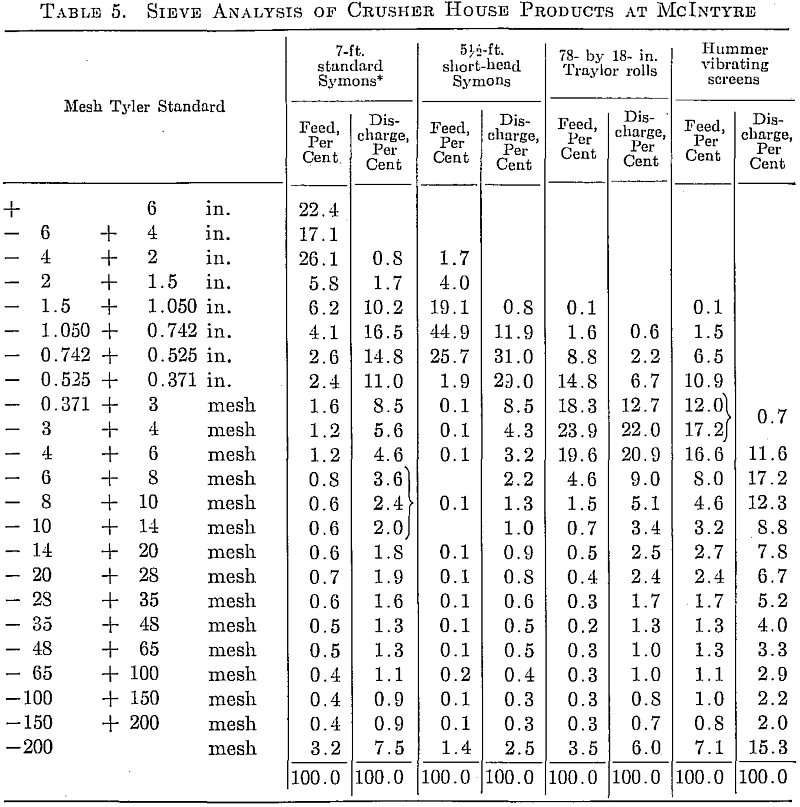

The crushing plant at the McIntyre Porcupine has been changed over in recent years from a three-stage to a four-stage operation. The mine ore is first crushed underground to about 7-in. size, then hoisted to the surface and stored in a 700-ton ore bin.  From here it is fed to a standard 7-ft. Symons cone crusher which discharges to two Symons rod deck screens with the ½-in. slots set transversely to the flow of ore. These screens are closed-circuited with a 5½-ft. Symons short-head crusher, and the undersize is passed to a bank of six 4- by 6-ft. Hummer screens having 3/16- by 5/8-in. openings. The oversize passes to the fourth stage of crushing—Traylor 78- by 18-in. rolls, the product of which is returned to the screens, while the undersize passes to the mill bins. See Table 5 for the analysis of Crusher house products.

From here it is fed to a standard 7-ft. Symons cone crusher which discharges to two Symons rod deck screens with the ½-in. slots set transversely to the flow of ore. These screens are closed-circuited with a 5½-ft. Symons short-head crusher, and the undersize is passed to a bank of six 4- by 6-ft. Hummer screens having 3/16- by 5/8-in. openings. The oversize passes to the fourth stage of crushing—Traylor 78- by 18-in. rolls, the product of which is returned to the screens, while the undersize passes to the mill bins. See Table 5 for the analysis of Crusher house products.

New Crushing Technologies

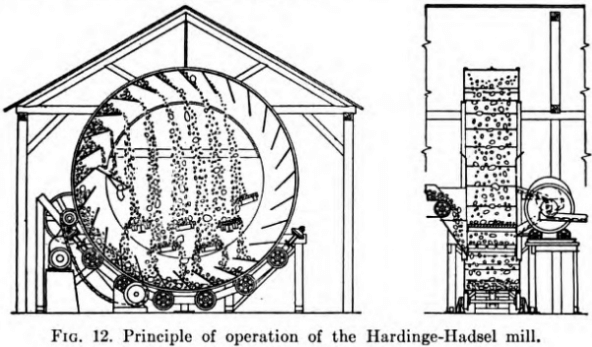

The Hadsel mill (see Fig. 12) is a new type of wet- crushing device which has found limited but interesting application. A large wheel, up to 24 ft. in diameter by 4½ ft. wide, is fitted with internal buckets. As the wheel revolves, the buckets lift the rock to the top of the mill where it is dropped onto stationary breaker plates. The ore is thus crushed by its own impact on the plates. Ore as large as 12 in. is fed to the mill.

The 7-ft. Symons discharge is separated on Symons screens into +½ in. and -½in. fractions. These screens are in closed circuit with the 5½-ft. short-head Symons crusher. Symons screen undersize is Hummer screen feed. Hummer screens are in closed circuit with the rolls.

The following notes are quoted from the article “Three Years of Operation with a Hadsel Mill” by George A. Bell. E. and M.J., Vol. 141, No. 1, p. 32, which, describes an installation at the Demonstration Gold Mines, Ltd., Baguio, Philippine Islands:

The ores are composed of andesite, quartz, breccia, calcite, and kaolinized material which forms a sticky gangue that can be put through an ordinary crushing plant only with great difficulty.

The capacity of the mill operating on a 12-in. feed and crushing through a 1-in. punched plate was 20 tons per hour, and power consumption about 3 kw.-hr. per ton of ore. The manganese-steel breaker plates lasted approximately 4 months, and other wearing parts 12 months.

In conclusion, the author states:

- The mill is ideal for crushing wet and sticky ores in one stage.

- The mill is mechanically sound and will crush to any desired size of ball-mill feed efficiently.

- Operating cost per unit of actual work is less than with standard machines.

- There is considerable saving in equipment.