Table of Contents

AUTOMATIC SAMPLERS

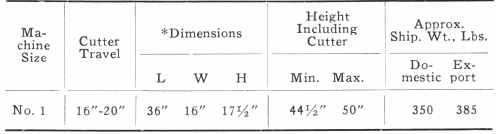

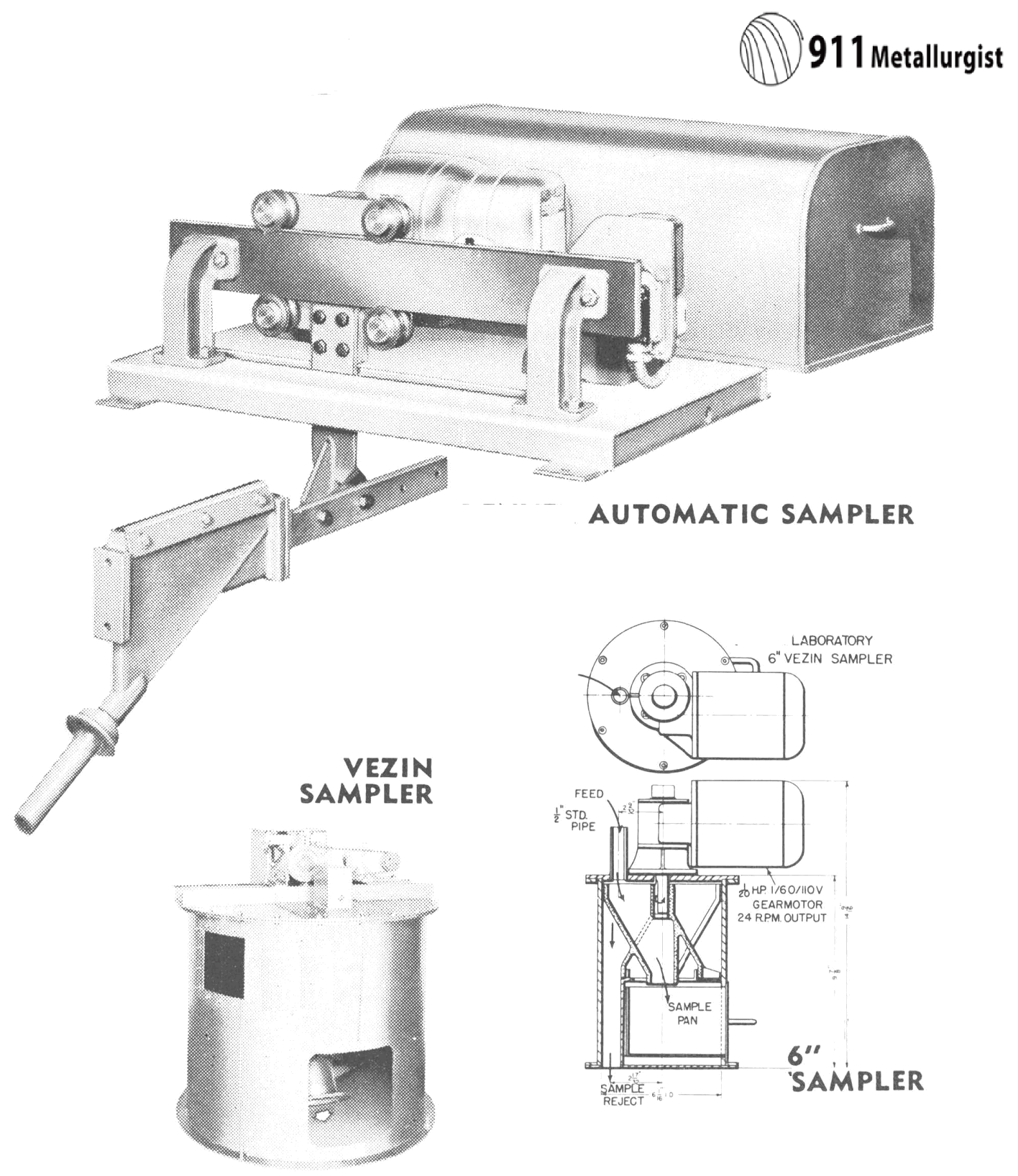

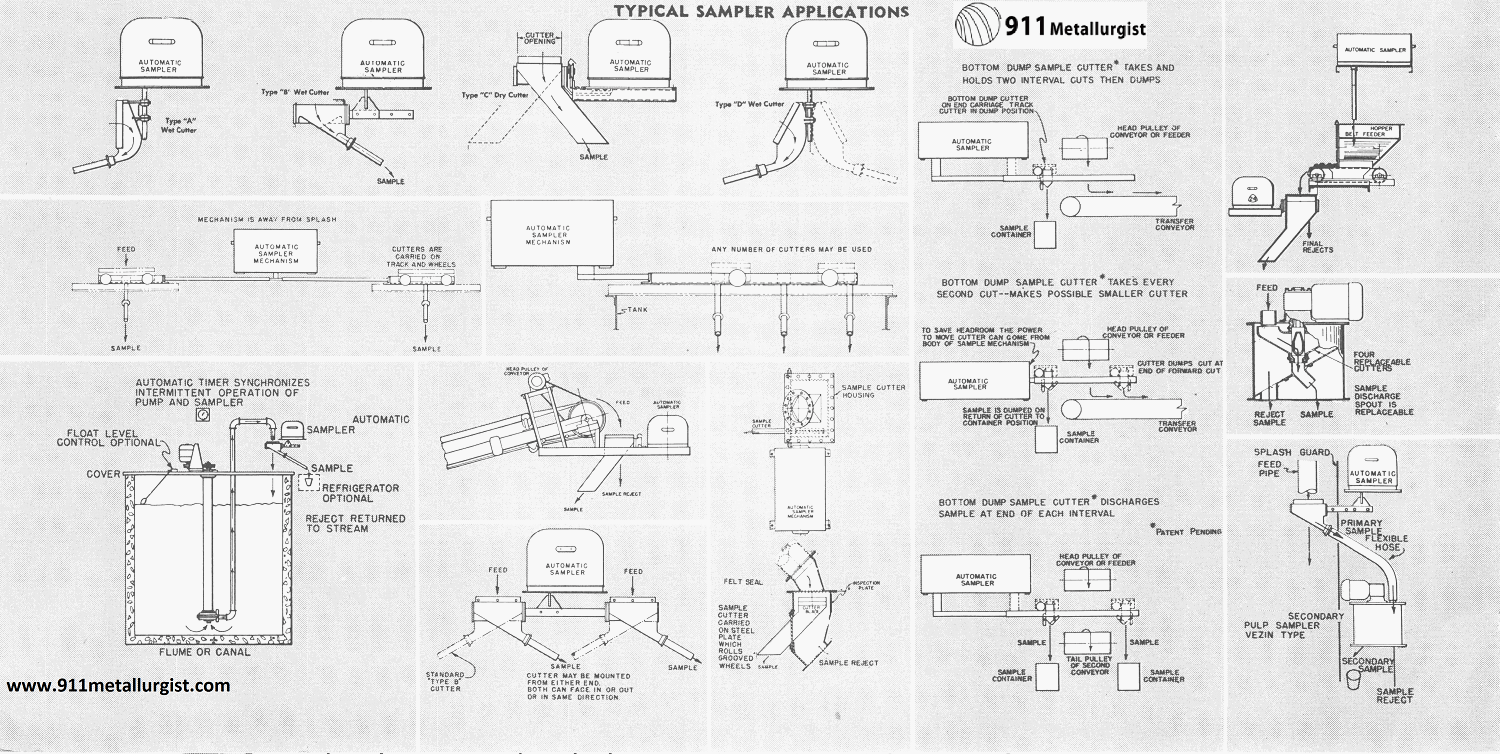

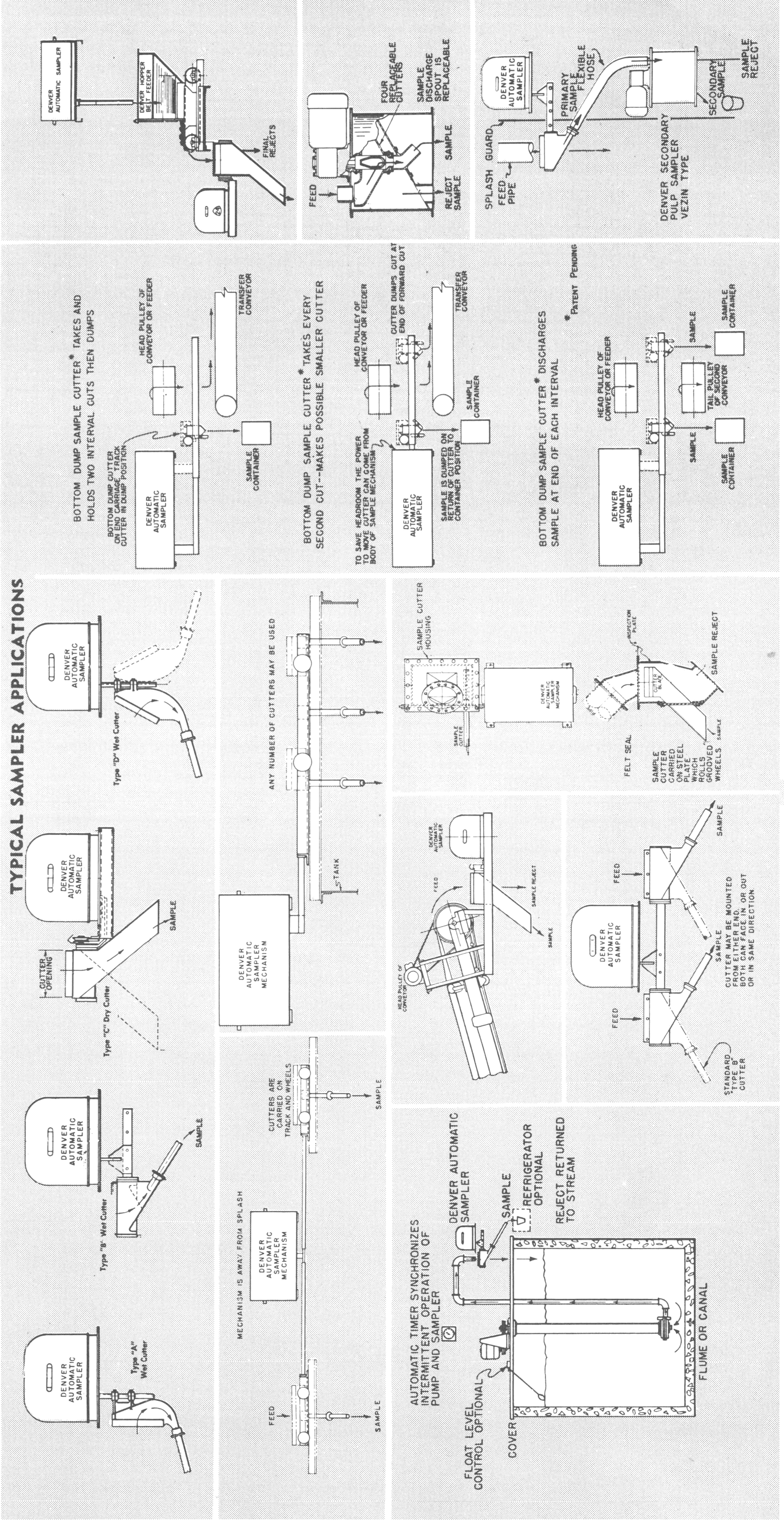

A compact unit designed to move the sample cutter through the stream at a uniform speed up to 30″ per second to provide an accurate increment sample. Action of cutter and mechanism closely adheres to theoretical “perfect technique” in cutting a sample. High speed cutter travel often eliminates need for secondary sampling. Sample cutter travel to 10′ and longer. Dust-tight units and bottom dump sample cutters for use in restricted headroom areas available.

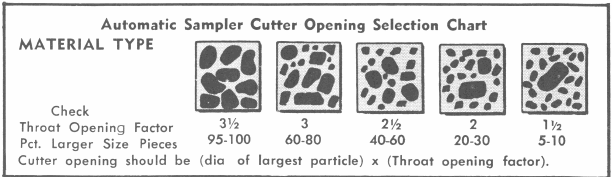

EXAMPLES BELOW: Pounds of sample taken per cut when feed rate is 1-Ton per hour. Multiply weight of sample by number of increment cuts per hour to determine weight of sample per hour.

VEZIN SAMPLERS

The Vezin is a self-contained, dust-tight unit designed to take increment samples from a vertical stream of dry materials continuously or at adjustable and predetermined intervals. Ideal for use with pneumatic conveying systems.

DUPLEX SNYDER SAMPLERS

The Snyder Sampler is a self-contained unit designed to operate continuously and remove increment samples to provide a sample of 5% (using one cutter opening) or 10% (when using two cutters). Duplex model also available to remove increment samples at both primary and secondary stages to provide a final sample of ¼ of 1% when each stage uses one cutter.

SAMPLE SPLITTERS

Sometimes known as a “riffler” unit, the Sample Splitter is designed to reduce the bulk of material to a convenient size for laboratory analysis. When used properly it provides accuracy recognized throughout the industry. A hopper is divided into several equal compartments. The compartments discharge in alternate directions to provide two portions of feed. Heavy construction, simple and easy to use and clean. In stock for quick shipment.

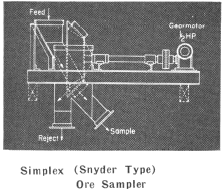

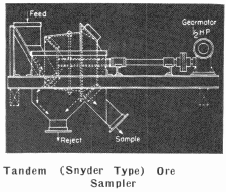

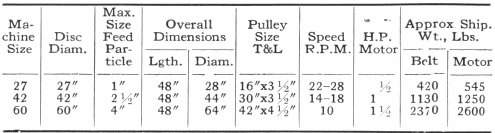

Snyder Ore Sampler

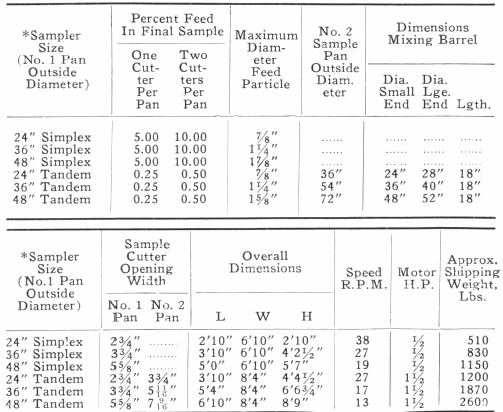

The (Snyder Type) Ore Sampler is available in both simplex and tandem units. The simplex unit is for final sample cuts of 5%, 10%, or 15% of the material fed to the sampler; and the tandem unit is for final sample cuts as small as 1%, or one-fourth of 1%, of the amount of material fed to the sampler.

All samplers include feed hopper and chute, sample pan or pans carrying one or more sample cutters, sample and reject housings, and horizontal shaft and bearings. Shaft is direct-connected through coupling to gearmotor, thus driving the sample pan or pans at a uniform rate of speed. Tandem units are also provided with a mixing barrel which receives the first cut and, after mixing it thoroughly, discharges it through another sample pan, having one or more cutters, which cuts out the final sample.

(Snyder Type) Ore Samplers have all parts mounted on a structural steel frame, requiring only two steel or wood supports to place the sampler in proper position to receive the material to be sampled. Sampler feed may be taken from the discharge of a belt conveyor, elevator, or an ore chute.

These samplers are of all steel construction and designed to provide maximum accuracy in the sampling of materials. Both simplex and tandem units are very compact, requiring only an absolute minimum of headroom.

More complete information can be obtained by writing any Equipment Company office.

Other Sizes of (Snyder Type) Ore Samplers, both larger and smaller available if required. Also, special types of these samplers to solve particular problems can be provided when the need arises.

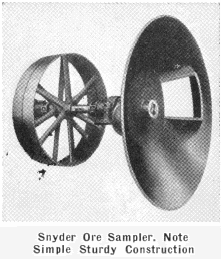

Snyder Ore Sampler

The Snyder Sampler is one of the most simple and efficient sampling machines ever devised. It consists of a circular casting, having one or more openings (depending upon the per cent sample desired) in its sloping flange, and mounted on the end of a horizontal shaft.

The ore to be sampled is directed by a spout so that it falls inside the flange of the sampler. The rejections slide off the flange into a hopper while the samples fall through the cutter.

A large number of these samplers are in operation and in every instance they are giving satisfaction.

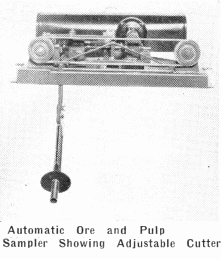

Automatic Ore and Pulp Sampler

The Automatic Ore and Pulp Sampler will very accurately sample either wet or dry material by positive mechanical means which insures constant, reliable, sampling results. It can be quickly installed and it makes a positive cut at accurate, predetermined intervals. The construction is all metal and the unit is equipped with a protecting cover and an adjustable cutter.

This sampler is economical, having no expensive and complicated electrical devices to regulate the cutter. An ingenious reducer arrangement has been designed which immediately engages the cutter at the correct interval, and a synchronous motor gives electric clock precision. The entire unit is mounted on a welded steel base and is very compact in design. Two types of cutters can be supplied; either a cutter for horizontal work or a cutter for vertical work.

The time intervals available between cuts are constant and can be set for 12, 8, 5.33, 4, 2.66, 2, or 1.5 minutes at 60 cycles, and 14.4, 9.6, 6.4, 4.8, 3.2, 2.4, and 1.8 minutes at 50 cycles. Maximum length of travel of the cutter is 20 inches. Standard motor is 110 volt, 60 cycle, single phase.

When ordering specify: (1) Current; (2) Sampling interval (minutes); (3) Type of cutter, either horizontal or vertical blade; (4) Whether material is wet or dry (if dry, what is size of largest piece).

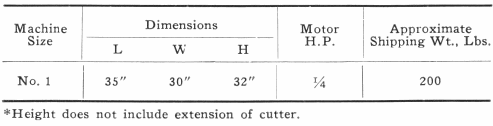

Automatic Ore and Pulp Sampler

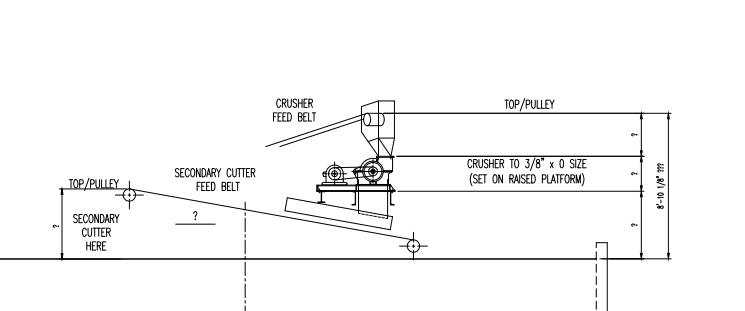

The Geco Automatic Ore and Pulp Sampler is designed to operate suitable sample cutters for the intermittent removal of accurate samples from streams of wet or dry materials at predetermined time intervals. The cutter is supported from the carrier block of the mechanism, and with the mechanism located in proper relationship to the stream of material to be sampled, the operation of the mechanism moves the cutter through the stream in a straight line and at a uniform speed. As it passes through the stream, the cutter is designed to deflect a representative portion of the stream into a suitable container.

The driving unit of the Geco Automatic Ore and Pulp Sampler is a gearmotor, operating only intermittently and controlled by a time switch. A roller chain, driven by a sprocket wheel mounted on the gearmotor shaft, is carried over an idler sprocket wheel. This sprocket wheel runs upon an axle supported by a pedestal bearing which also provides for adjustable chain tension.

The sample cutter, suspended from the carrier block, is moved back and forth by the engagement of an extended pin connecting two links of the chain with the disengaging arms mounted on the carrier block.

The direction of the cutter travel is reversed, after each succeeding sample cut, by means of the opposite directions of travel the extended pin assumes in following the path of the chain travel over the sprockets.

At the limits of the carrier travel, energy to the motor is cut off by the opening of a limit switch and the carrier remains at rest until the circuit is restored by the time switch through the second limit switch at the opposite end of the carrier travel.