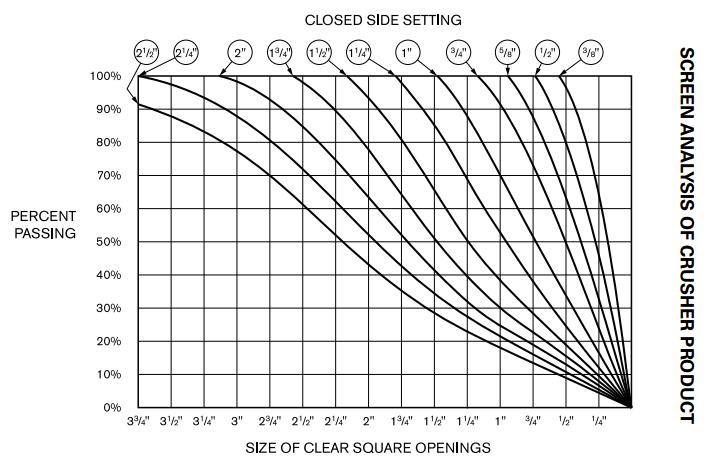

The feed to a crusher should not contain an excessive amount of fine material; this could be stated a little more definitely by saying that it should not contain an excessive amount of material smaller than the crusher product size. Just what constitutes an “excessive amount” depends of course upon several factors, chief among which are the design of the crushing chamber, the setting, and the character of the material being crushed.

Quarry operations do not usually require scalping ahead of the primary crusher, although there are exceptions to this. Gravel pit and mining operations almost always require scalping ahead of the primary machine because of the large percentage of fine material in the pit-run, or mine-run, material. Generally, when scalping is required at this point, the split is made at approximately the open-side of the primary crusher.

Screening between the primary and secondary stages is always desirable, although it is by no means a universal practice. Where very large primary crushers are involved with accompanying large size product it has been common practice in the past to pass the product of the primary machine directly into the secondary. So far as product gradation is concerned, this is equivalent to making the entire reduction in one machine, and it is inevitable that such a practice will increase the amount of fines in the overall plant product. This practice of past years can be attributed to the lack of proper screening equipment to handle the coarse product of these large primary crushers. Now that screens are available to clean this coarse material, there is no longer any excuse for such an arrangement.

Screening ahead of fine-reduction crushers is not only desirable, it is imperative from the standpoint of both safe and satisfactory operation. Preferably, all material smaller than the crusher-product size should be removed from the feed. There is an old saying to the effect that, “It is cheaper to screen than it is to crush,” which is trite but true. The fine-reduction works on all material that enters its crushing chamber, regardless of whether or not the material is smaller than the discharge setting. This work takes power, makes more fines, increases wear on the liners, and may actually cut the capacity of the crush’ er, due to sluggish movement of the fine material. When we add to these the greatly increased probability of a choke occurring with the unscreened feed, the case for a clean, screened feed to the fine-reduction crusher is clear cut and incontrovertible.

https://www.metso.com/