These are; working with and aiding other personnel and maintaining good housekeeping standards. These two definitely go together. You won’t have good housekeeping standards if you don’t work with and aid the other workers. Like it or not, good housekeeping is very important to the entire operation. If the plant is kept clean morale will be high, production good, and most important the plant will be a safer place to work in.

There is one more subject that I would like to touch on now. Like the many of the subjects that we have talked about, this too will he discussed in detail later. As you probably already guessed the subject is SAFETY.

Governments make laws and set guidelines for companies to follow. This is to ensure that working conditions are safe, and that workers have at least the minimum amount of protection to ensure their safety. Companies in their turn make rules and regulations designed to protect workers from accidents. When you get right down to it, the only person who has the authority and the responsibility to ensure that you are working safe is yourself. Safety is an attitude, not rules or regulations, it is how you do your job. In the majority of cases, to have safe working conditions require no more than a level head combined with some common sense rules.

First, be fit and well rested for each day, next, be sure that your area is clean and organized. Thirdly know and understand the tasks that are being assigned to you.

If you are required to perform a duty that you are unsure of, I would suggest that you express your unease to your supervisor. Perhaps a review of any procedures that you are uncomfortable with is all that is needed to clear any feelings of doubt that you are experiencing. Remember that a supervisor’s responsibility lies in ensuring that the work is done correctly and safely. Most supervisors would prefer having an employee spend a little extra time checking and making sure than a lot of time repairing any damage that was done in ignorance.

Concentrator Housekeeping Method -How to Keep a Mill Clean

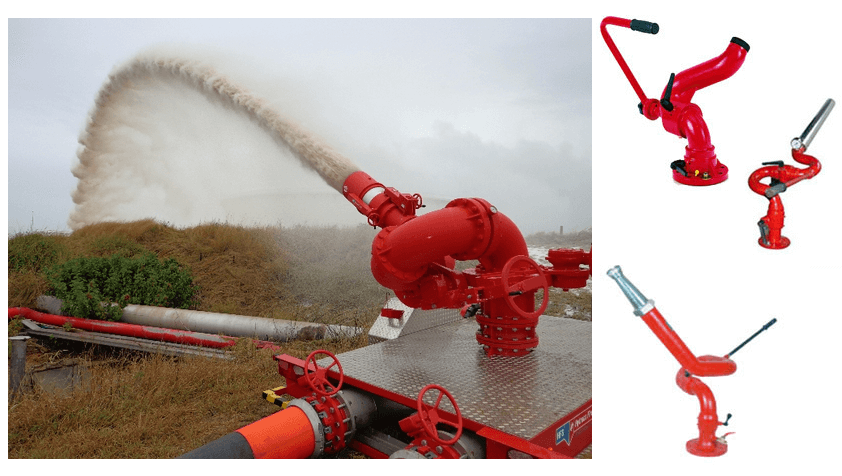

The first one is divided into two parts, SHOVELLING and HOSING. There are many different types of shovels, each one designed for a special job. As a mill operator the two that you will use the most are either the ROUND MOUTHED or the SQUARE MOUTHED. You will find that when you are working doing clean up on a cement floor, or any flat surface, the square mouth shovel is the easiest to work with. The round mouth works best when digging into a pile of rock or the earth itself.

|

|

To make your digging easier I would like to let you in on a couple of tips. First, when you lift a load that is on your shovel, don’t lift with your back. Use your leg as a pivot point, put your weight onto the end of the shovel handle and lean backwards. The shovel will lift much easier.

If your muscles are getting tired switch to a different shovel handle. There are two types, a LONG HANDLE and a “D” HANDLE. The change in length will cause different muscles to be used and prevent you from getting as tired. The two types of shovel handles can prevent blisters as well. If you feel a blister developing, switch to the other-type of handle”. The hold on each is different. This will change the pattern of irritation.

When an operator uses a WATER HOSE for clean up, a couple of bad ideas are often acted on. Many people think that water hoses are play things or weapons of retaliation for bad jokes. They are not. Used in this manner they can become very dangerous. Electrocution, loss of eye sight, bad falls, all may result. What I am saying is use water hoses for what they were designed for, to make your job easier.

The last important tip I can give you about using water hoses for clean-up is to do with the pump that you wash the spillage into. It is simply to keep the feed screen to the pump clean. Each type of SUMP PUMP (A sump is a collection reservoir or pit, a sump pump is a pump that pumps the material that is in the sump) has a screen over its feed throat to prevent anything that may damage it from getting caught in it. Plastic, wood and other garbage will plug this screen preventing the clean-up solids from entering the pump.

10 Rules for Working Safely in a Concentrator

- ALWAYS wear your hardhat and safety boots at ALL times in ALL plant areas.

- ALWAYS obtain protective clothing from your supervisor when necessary.

- NEVER walk underneath loads suspended by cranes or monorails.

- ALWAYS keep your working area clean and tidy at all times.

- ALWAYS check the condition of walkways, handrails and ladders before using them. ALWAYS use walkway handrails.

- ALWAYS walk NEVER run.

- ALWAYS check if people are working above/or below you.

- ALWAYS use a safety belt if working in an area with ANY danger of falling.

- ALWAYS check that your working area is tidy and equipment you are using is in good condition.

- If you think ANY action will endanger your personal safety, STOP, THINK AND TAKE NECESSARY PRECAUTIONS.

https://www.911metallurgist.com/good-concentrator-safety-guidelines-practices