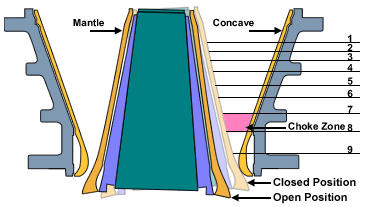

It is entirely possible for a crusher to choke at some other point in the crushing chamber than the theoretical choke-point. When the setting of a fine-reduction crusher is too close for its eccentric throw and for the general proportions of its crushing chamber, there is a tendency toward building up a choke in the zone immediately above the discharge opening, regardless of where the theoretical choke-point is located. The reason for this is that the excessive movement of the head (in relation to the discharge setting) mashes the material against the concave so tightly that the individual particles are shattered, or pulverized.

It is entirely possible for a crusher to choke at some other point in the crushing chamber than the theoretical choke-point. When the setting of a fine-reduction crusher is too close for its eccentric throw and for the general proportions of its crushing chamber, there is a tendency toward building up a choke in the zone immediately above the discharge opening, regardless of where the theoretical choke-point is located. The reason for this is that the excessive movement of the head (in relation to the discharge setting) mashes the material against the concave so tightly that the individual particles are shattered, or pulverized.

Such a crushing action builds up fines very rapidly, and consequently brings about a rapid reduction in the percentage of voids, even though the crushing chamber may have a progressive volume-expansion characteristic. Many materials, when mashed in the manner described, tend to cake, and to cling to the crushing surfaces; the movement becomes sluggish; more material crowds down from above, aggravating the packed condition, and, if the action progresses to the point where all voids are eliminated, a choke results.

Characteristics or condition of the material have a decided influence upon the action just described. Soft, friable rock is more apt to pack than hard, clean-breaking rock; damp material is more prone to cause trouble than dry, particularly so if the feed contains many fines (e.g., unscreened feed).

In the case of the high speed crusher, there will naturally be occasional pieces get through that are a little larger than the close-side setting. but these are so few that they are unimportant.

Products of High and Low Speed Crushing

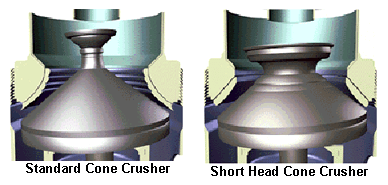

It is important to note that the products of the two classes of crusher (low-speed and high-speed) cannot be compared directly upon the basis of their respective open-side and close- side settings. Nor, can the products of any two types in the high-speed class be compared upon this basis, unless it is known that their speeds, throws, and general shape of crushing chamber are similar.

As between crushers of the high and low speed types, the low-speed machine at any given open-side setting will make a finer product than will the high-speed machine at the same closed-side setting. For example, in one installation where the machines are working on the same material, a standard type gyratory, fitted with non-choking concaves,consistently delivers a product 85% of which passes a square-opening test sieve equivalent to its open-side setting. A high-speed, gyratory, cone crusher or fine-reduction crusher in the same plant just as consistently produces material 70% of which passes a square opening test sieve, equivalent to its close-side setting. In both cases all material is reduced to a one-way dimension not exceeding these respective open and close-side settings. This is a typical case which gives a pretty fair average comparison of products from machines rated on these two different bases.

https://www.911metallurgist.com/why-screening-crusher-feed-is-important

These results might, at first glance, appear to be inconsistent in view of the fact that the maximum one-way dimension is established in each case by the respective open and close side positions, whereas the product analyses do not show similar percentages passing these respective opening sizes in the test screens. The apparent inconsistency clears itself up, however, when we remember that the low-speed crusher, as well as the high-speed machine, does its sizing on the close-side of its stroke. The governing point is the distance (above the discharge point) that the material can fall (once it has been broken to a one-way dimension less than the open-side setting) before the head can catch it again. In the high-speed crusher this point is quite close to the discharge opening; in the low-speed machine it is some distance above the opening, the amount depending upon the shape of the crusher chamber, as was made clear in our discussion of the preceding diagrams.

It is hardly practicable to rate the product of a high-speed, short-throw crusher at its open-side setting. In the case just noted, all of the product of the second crusher mentioned, except for an occasional flat spall, passes a square-opening test sieve equivalent to its open-side setting; in fact, at some combinations of setting and throw,  the 100% point will be below the open-side setting. It is impossible to gauge a crusher product at, or near, the 100% passing point because a few flat spalls, more or less, in the sample will throw the analysis several points one way or the other, giving results that are uncertain.

the 100% point will be below the open-side setting. It is impossible to gauge a crusher product at, or near, the 100% passing point because a few flat spalls, more or less, in the sample will throw the analysis several points one way or the other, giving results that are uncertain.

There is a very wide variation in the product delivered by different types of high-speed crushers at similar close-side settings. Short-throw crushers tend to give fairly consistent results, even on materials of divergent physical characteristics. The product of crushers with large throws, and lower eccentric speeds, will vary more widely, depending to a much greater extent upon the nature of the material. In judging the relative merits of crushers which are rated at their close-side settings, a check should be made to determine just what kind of product the crusher will deliver, with reference to any particular setting.

https://www.911metallurgist.com/crusher-reduction-ratio