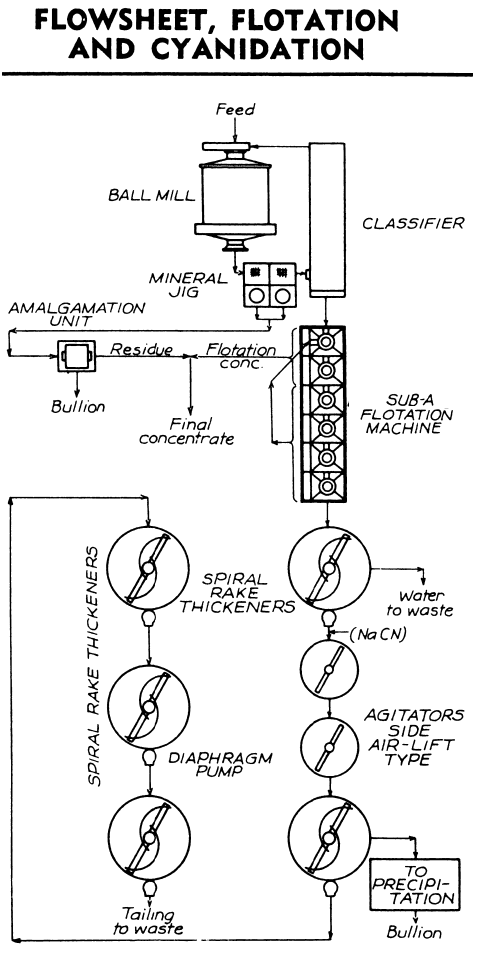

Flotation, Gravity and Tailings Cyanidation

DESCRIPTION: Flotation with cyanidation of flotation tailings. This flowsheet has a gravity gold recovery embedded into the grinding circuit’s ball mill discharge. ORE TREATED: Ores containing both oxide and sulphide minerals with gold or silver, or those with cyanicides which must he removed before cyanidation. ADVANTAGES: This flowsheet makes possible the milling in one plant […]

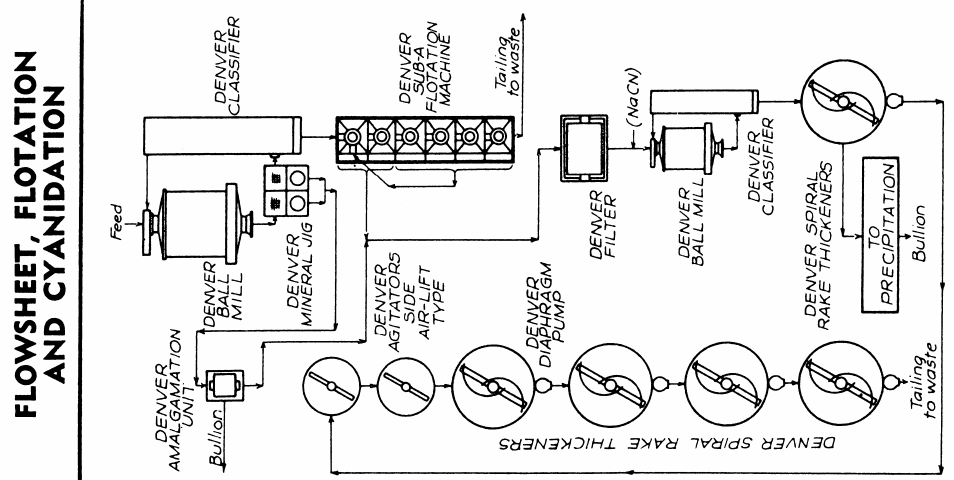

Flotation & Cyanidation Leaching of Concentrate

DESCRIPTION: Flotation followed by cyanidation of flotation concentrates. In this flowsheet the flotation concentrates produced are reground and treated by cyanidation leaching. ORE TREATED: Sulphide ores wherein base metal values are negligible (such as pyrite) but with good gold and silver values, or in cases where increased returns can be secured from the marketing of […]

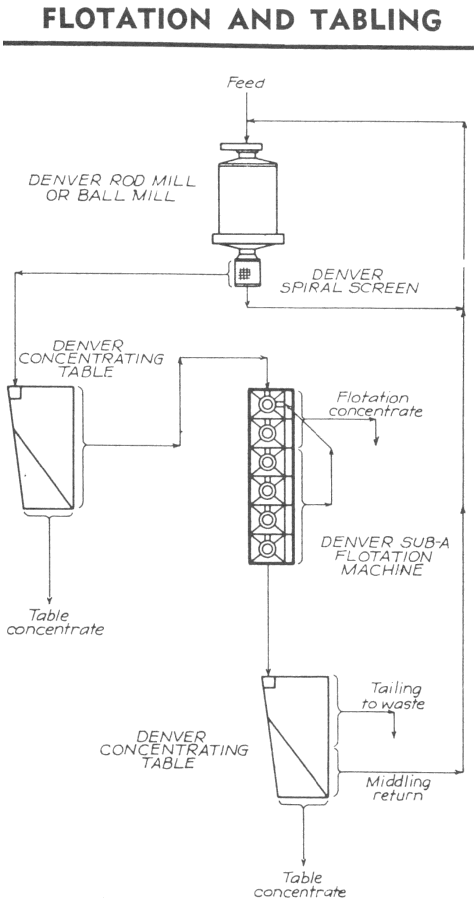

Flotation & Shaking Tables with Open Circuit Ball Mill

DESCRIPTION: Flotation followed by shaker table concentration in open circuit grinding. ORE TREATED: When the mineral in an ore is freed at a coarse mesh, this flowsheet gives high recovery and high capacity. The practice is limited in scope, as on ores requiring fine grinding, closed circuit is preferable, and on ores wherein the gold is free, amalgamation […]

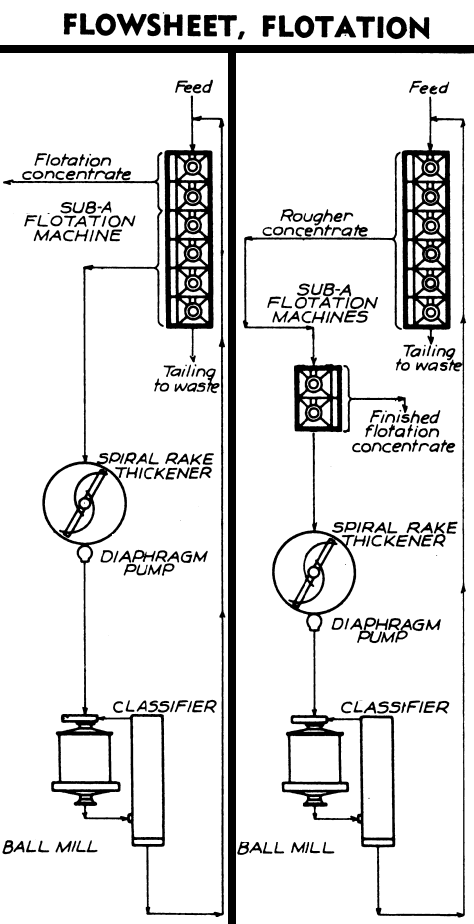

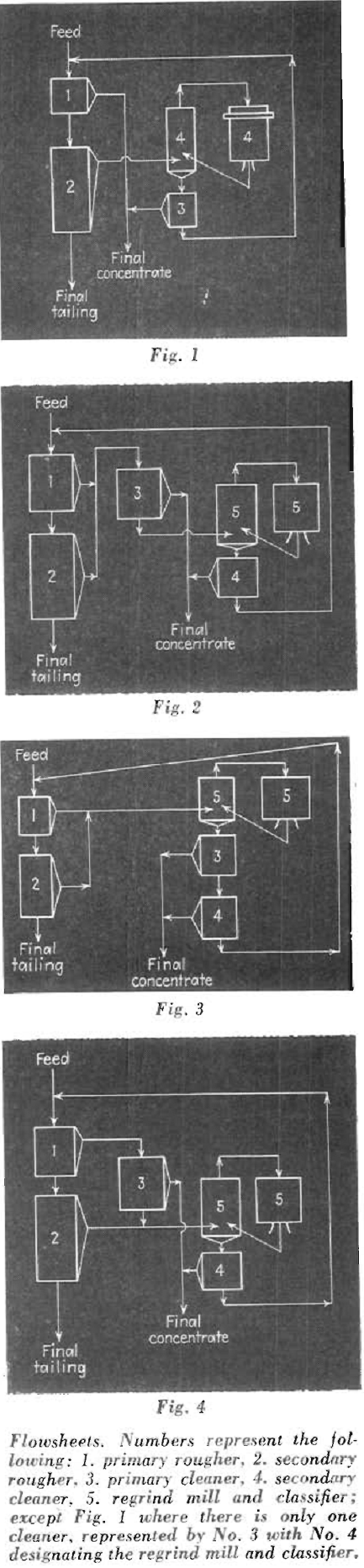

Closed Circuit Flotation with Regrinding Flowsheet

DESCRIPTION: Regrinding of scavenger flotation concentrate middling OR flotation cleaner tailing and refloating the ground product in closed circuit cleaning. ORE TREATED: Flotation middling containing valuable mineral particles attached to the gangue particles and which can be freed by finer grinding. ADVANTAGES: Middling is designated as such because it contains material which lowers the grade of […]

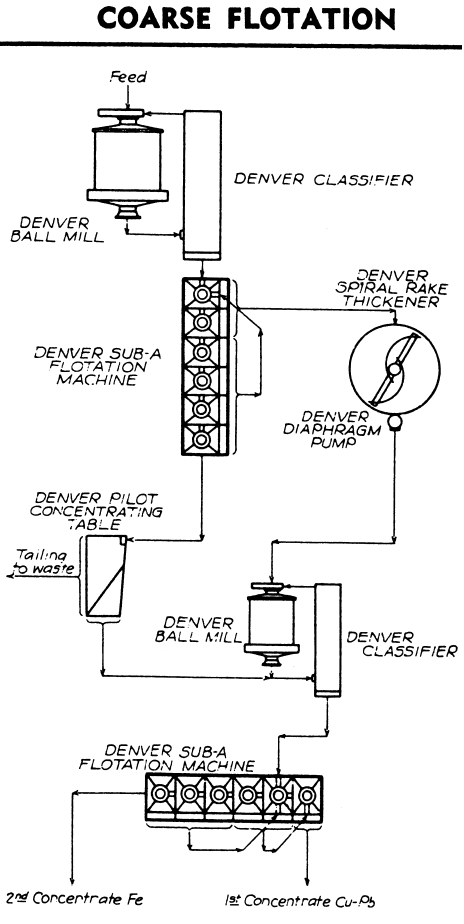

Coarse Flotation with Gravity & Regrind Circuit

DESCRIPTION: Coarse flotation followed by regrind of coarse rougher concentrate and selective flotation or cleaning. Coarse flotation tailings and reground rougher concentrate are processed over a shaking table for precious metals. ORE TREATED: Ores wherein the minerals can be freed from the gangue at a coarse mesh and subsequently separated from each other after finer grinding. […]

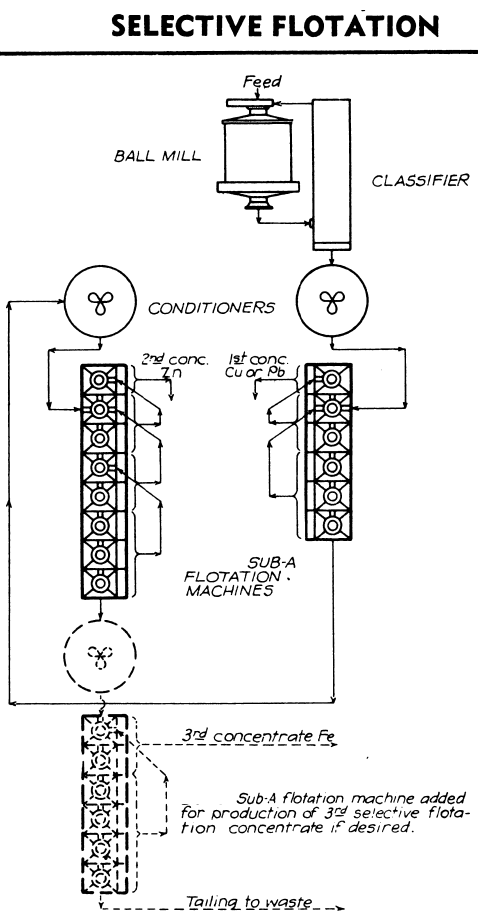

Sequential Selective Flotation Process Flowsheet

A selective or sequential flotation flowsheet of two or more products. By utilizing selective flotation, two or more minerals in an ore are separated into individual high grade products. ORE TREATED: The most common of ores treated in this manner are lead zinc, copper-zinc-iron, copper-nickel, but application may be made to other two or three […]

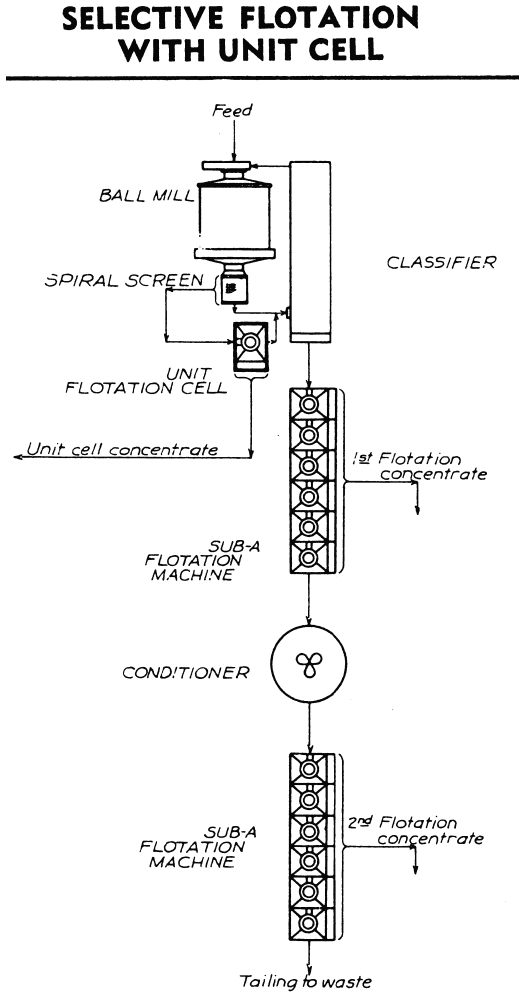

Flash Flotation in Gold Circuit – 2 Product Processing

DESCRIPTION: Flash Unit Flotation Cell in selective “gold” flotation circuit. ORE TREATED: The widest application of this flowsheet is on lead-zinc ore treatment, although it also can be applied to some gold ores as well as molybdenum ores containing other sulphides. This circuit is very similar to the now closed Cominco Polaris mill has; an ‘in-grinding’ […]

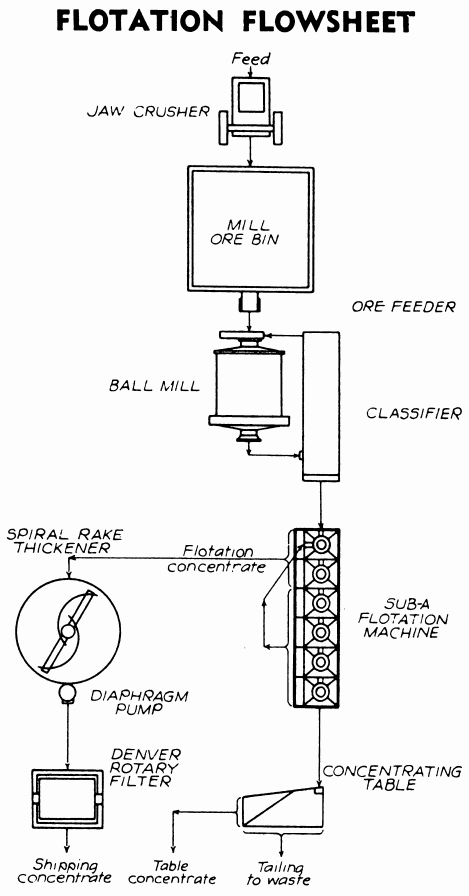

Simple Flotation Flowsheet – 1 Product

DESCRIPTION: A Straight flotation flowsheet of one product showing flotation machine treating ground and classified pulp. ORE TREATED: Base metal ores containing a single valuable mineral such as a copper or lead sulphide, and complex gold and silver ores, are economically handled with this simple flowsheet. It is commonly used where fine grinding is required and […]

Mineral Processing Flowsheets

The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling equipment. The Flotation Machine, the Selective Mineral Jig and […]

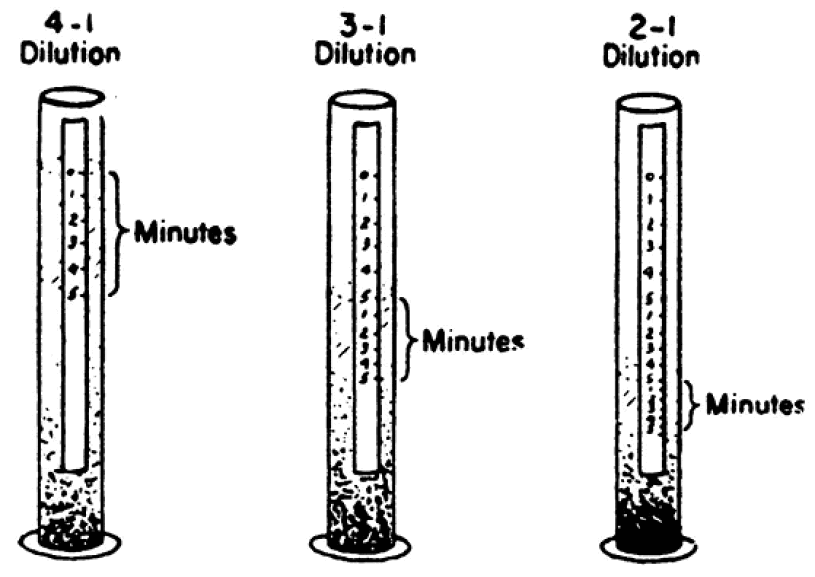

How to Size a Thickener

Knowing how to size a thickener and determine the capacity required to handle a pre-determined tonnage of a certain pulp, by overflowing a clear solution and obtaining the desired pulp density of thickener discharge, depends upon the settling rate of that particular pulp. The settling rate of any pulp is easily determined by simple laboratory tests […]