Gold Metallurgy Accounting

Everyone connected with cyanide plants has at some time or another been confronted with a real or apparent shortage of bullion in the clean-up, that is, the bullion recovered has been less than the amount expected when calculated from the assays of head and tail and the tonnage treated. Such a shortage will often occur […]

Continuous Gold Leaching and Tanks Short-Circuiting

The system of continuous treatment consists in allowing the stream of pulp to flow continuously through a connecting series of agitator tanks, as distinguished from the intermittent system where a charge is placed in a tank and agitated therein until the dissolution of the precious metals is complete. It may be applied to almost any […]

Gold Losses in Continuous Countercurrent Decantation

This is an interesting development of the old decantation process, and while it contains the same principle, of displacement by successive dilutions, the action is much more rapid, the same result is attained by the use of considerably less barren solution and it is continuous in action needing little power and practically no attention. For […]

Pulp and Slurry Thickening Test and Calculations

The slime pulp or slurry on leaving the sand classifier with its proper admixture of lime is first led to some form of thickening device if, as is usually the case, the ratio of liquid to solid is too large for economic handling in the cyanide treatment. The form of thickener almost universally used in […]

Leaching Fine Gold

Many definitions of the word “slime” have been attempted to Leaching Fine Gold but the one that best expresses its meaning from a practical point of view is that given by Park that it is that part of the pulverized ore that is not percolable on a commercial scale without the use of pressure. The […]

Leaching Gold from Finely Crushed Ore (Sand Leach)

When the cyanide process was first introduced its application was confined to leaching, that is, treatment by percolation. By this method only such material could be worked as was sufficiently granular in texture to allow the necessary amount of solution to percolate through it in a reasonable time. By crushing the ore dry, it is […]

Free Cyanide vs Total Cyanide Determination

It is obviously of the highest importance in controlling the action of a solution to find out what strength of cyanide and alkali it contains at any given time. Under this head are the tests for free cyanide, “total” cyanide, hydrocyanic acid, and free or “protective” alkali. Besides these cyanide constituents, which have to be […]

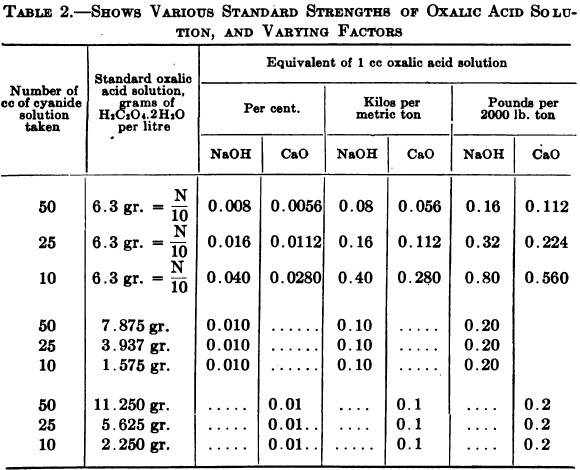

Method to Measure Lime Content in Cyanide Leach Solution

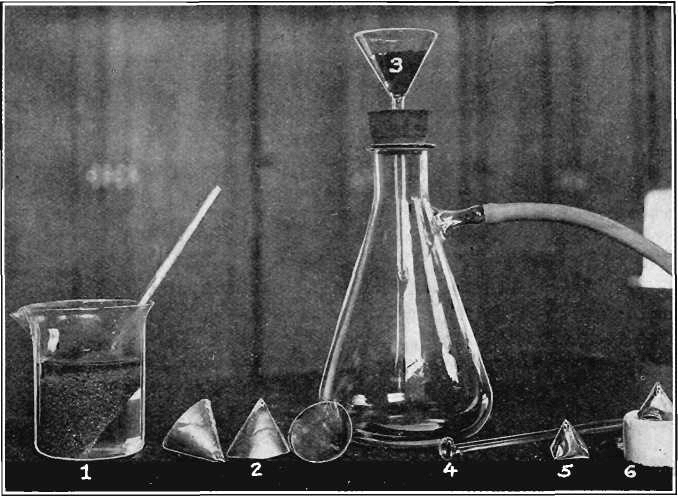

This term is usually defined as “the alkaline hydrates and half the monocarbonates” whose action is to protect the cyanide from decomposition, by acids developed in the ore and by atmospheric carbon dioxide. Either oxalic acid or a mineral acid may be used as a standard solution. Objections have been raised to the use of […]

Assay Method of Zinc in Cyanide Leach Solution

To ascertain the presence of zinc add a few drops of sodium sulphide solution to 50 cc of the solution to be tested (which should be strongly alkaline), and heat to boiling point. If zinc is present it will come down as a flocculent white precipitate. It sometimes happens that a cyanide solution will contain […]

Measure Copper Content of Cyanide Leach Solution

To assay for copper contained in a cyanide solution, the first essential step of the method is to completely decompose all the cyanogen compounds. For this purpose Clennell recommends evaporating 100 cc of the solution to be tested with 5 cc of nitric and 10 cc of sulphuric acid until dense white fumes are freely […]