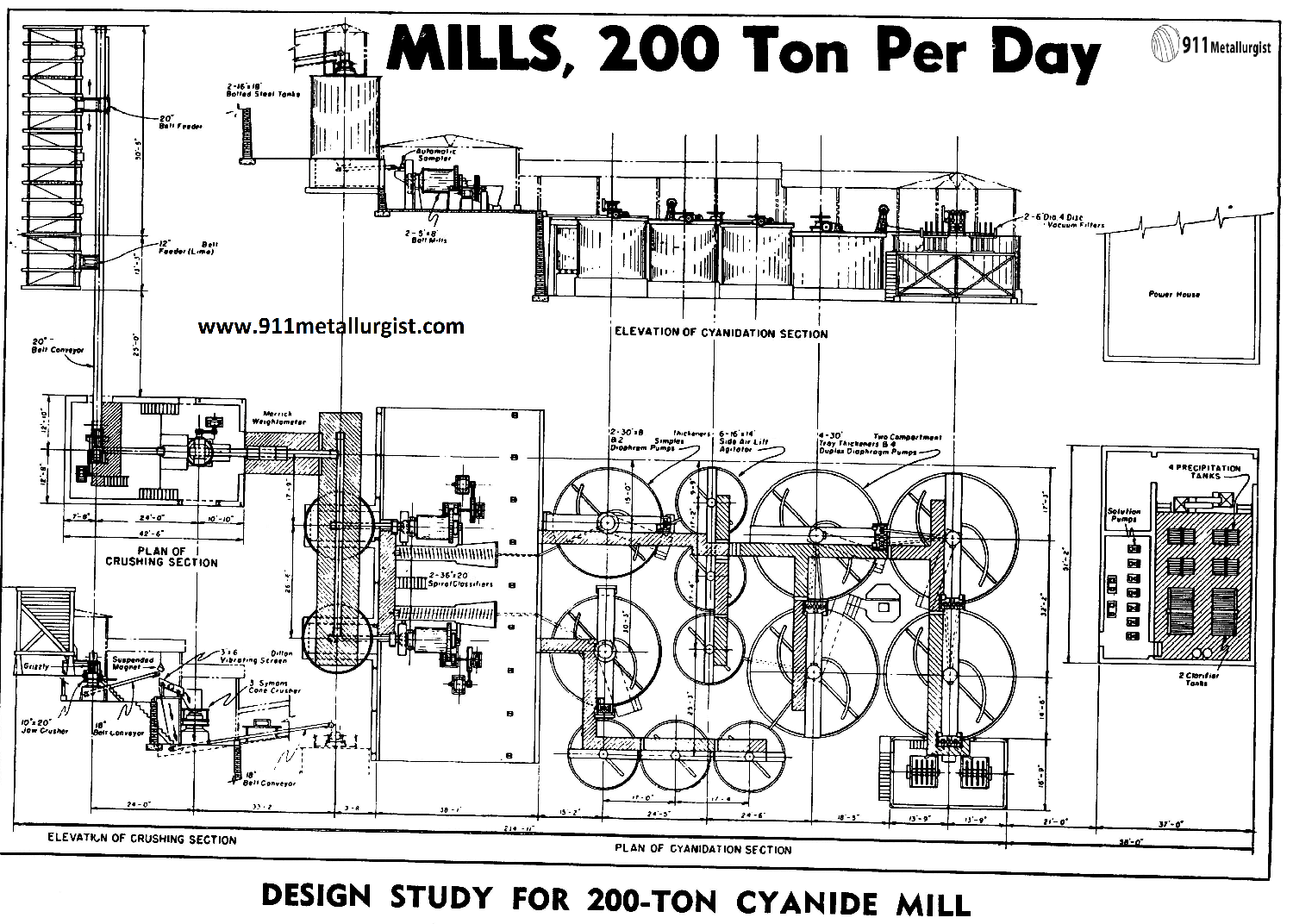

Small Gold Leaching Circuit Design

The gold cyanide leaching mill site is centrally located with respect to the mine, water supply and improved highway. This selection reduced both the length of the haulage road from mine to mill and main water supply line to a minimum. The location provided a sloping mill site, adequate tailings disposal area, housing space for […]

Intensive Cyanidation

The upgrading of gravity concentrate for smelting purposes by use of intensive cyanidation is still in the experimental stage. It involves the leaching out of the gold into solution, using a strong cyanide mix, and then the electrowinning of that solution so as to recover the gold on the steel wool cathodes. This system is […]

Gold Cyanidation Circuits

The principle of dissolving gold and silver values in solutions of potassium or sodium cyanide is old and has been thoroughly carried out in practice for many years. There have been only a few changes in the chemical procedure and also few changes in the type of equipment used. The gold and silver are dissolved […]

Designs for Small Portable and Mobile Gold Leaching Plant

Agitation capacity based on 36 to 48 hours of agitation time. Thickener area based on 6 to 7 square feet per ton of dry solids per 24 hours. Pregnant cyanide solution (Primary Thickener Overflow) is treated in a Precipitation System which includes: Clarifier, Vacuum Tank, Vacuum Pump, Clarifier Pump, Zinc Dust Feeder, Zinc […]

Gold Recovery by Batch Cyanide Leaching Plant

PROCESS FLOWSHEET DESCRIPTION: Batch Gold Cyanidation-Leaching Plant. ORE TREATED: Small tonnages of high-grade gold-silver ores and flotation or Jig concentrates amenable to cyanide treatment, used for treating as low as one ton of concentrates per day. ADVANTAGES: Where the tonnage of ore or concentrates is too low for standard continuous cyanidation plants (usually less than […]

CCD – Counter Current Decantation Flowsheet

PROCESS FLOWSHEET DESCRIPTION: Continuous counter-current decantation cyanidation flowsheet. ORE TREATED: Gold and silver ores amenable to the cyanidation process and where economics justify plant outlay. ADVANTAGES: By producing the precious metals in bullion form, the highest net return is realized on many gold and silver ores. Where the tonnage available for treatment justifies the capital […]

Agitated Leaching Circuit Operation

Ground slurry from the trash screen enters this EXAMPLE Agitated Leach circuit at a rate of 35.5 cubic meters per hour, and 45% solids. The slurry passes through each of the four tanks, and should remain in each tank for a period of approximately 12 hours. Each tank is 8 meters in diameter by 8.5 […]

Dissolve Gold and Silver with Cyanide

The addition of gold or silver to an alkaline sodium cyanide solution will cause the gold and silver to react with the cyanide and dissolve into the solution in a process called cyanidation. This process is more frequently referred to as leaching. As well as reacting with the precious metals, the cyanide will react with […]

Effect of Cyanide on Steel and Iron Minerals Leached by Cyanide

The corrosion of black rolled mild steel in sodium cyanide solution is negligible. A piece of steel suspended in a sodium cyanide solution maintained at 0.05% NaCN and 0.001% CaO, in the presence of air, lost 0.002% of its weight in two weeks, this was equivalent to a penetration of 0.76 micron per year.Oxidized iron minerals […]

Cyanide Diffusion pH and Oxygen

Whether lime titrations or pH control is belter depends, I think, on the level of control. If the level was down around 0. 1 lb per ton of solution, titration is a bit difficult without a highly skilled man, which is not always available. Around a pH of 11 or 11.5, a pH meter is […]