Amalgamation of Gold & Mercury

Any amalgamation test is found to possess most merits and fewest limitations when reduced to the smallest possible dimensions permitting uniform action and certain treatment. A limit is always reached at some point in this reduction in size, where some condition no longer can be fulfilled. In many continuous mechanical tests the limit is set […]

Steam Stamp Milling with Amalgamation

The use of steam-stamps in the crushing of ore for the purpose of amalgamation has been very limited, and little has been written on the subject. As the writer has been operating a mill of this kind during the past year, it is possible that he may be able to present a few points in […]

How Mercury & Gold Amalgamation Works

In order to keep the plates in proper condition so that successful amalgamation may be maintained, they must be prepared carefully, and the closest watch kept over them. The setting of the plates has already been described on p. 121. The silver-plated copper table is preferred in California from the ease with which it is […]

Gold Amalgamation Equipment

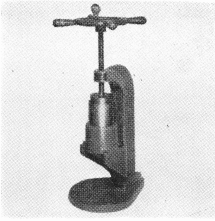

AMALGAM PRESS The Amalgam Press is used wherever the process of amalgamation is practiced. The amalgam is wrapped in a wet chamois skin and inserted in the press, which extrudes the surplus amalgam. The press consists of a steel cylinder, slotted on the sides and perforated on the bottom. The steel piston is forced into […]

Gold Amalgamation

The purpose of the following research, as originally planned, was to investigate the influence of temperature upon the plate- amalgamation process. In order to consider the gold amalgamation process intelligently, it was first necessary to learn the nature of an amalgam. In the performance of this task it was found necessary to consult a large […]

Recovery of Mercury from Amalgamation Tailing

In this paper on the recovery of mercury as sulphide, from the residues from the amalgamation and cyanide treatment of high-grade ores and concentrates, I will not discuss the many reactions, chemical and otherwise, that take place in the general process, but confine myself more particularly to the methods of recovering the mercury. I submit […]

Amalgamation Of Gold Ores & Chloritizing Roasting

The following minerals could be plainly seen in the ore: magnetite, pyrites of iron, pyrites of copper, quartz, and garnet. Neither galena nor zinc-blende were visible, but the ore contained a trace of lead, and in some samples of ore from the Muertos mine, 1.19 per cent, of zinc was found. Antimony and arsenic were […]

Pan Amalgamation

These results obtained in experiments, proving that a low percentage of copper sulphate with a variable percentage of salt, depending on the ore, gives the best results, confirm practical mill-work. I have none of my notes, taken at the time, to refer to, so have to rely solely on memory, which precludes the conciseness that […]

Amalgamation Patio Process

The ores were composed principally of iron pyrites (much decomposed), in a quartz matrix, with native gold in very irregular grains. Some portions, however, carried their metallic value in a matrix of calcite and siderite. The mill in which the ores were treated consisted of two 800-lb. stamps, two amalgamating-plates, four pans, two automatic washers, […]