Table of Contents

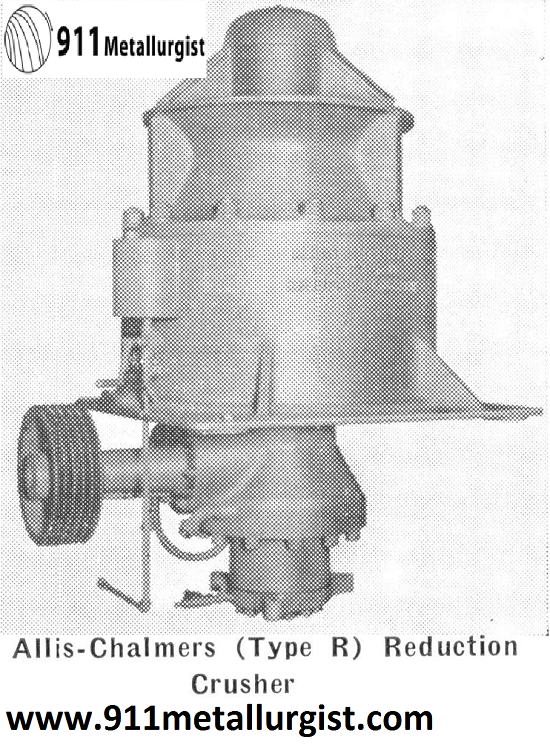

The Allis-Chalmers (Type R) Small Gyratory Reduction Crusher is designed for large capacity, fine crushing and incorporates many improvements over other gyratory type crushers previously manufactured by this company. The most distinctive feature of the Type R Crusher is the built-in, oil filled hydraulic jack used for fast, positive change of crusher setting while crusher is operating. The hydraulic step support also provides a convenient means of unloading the crushing chamber in case of power failure or other emergency. Protection against damage from tramp iron is automatically provided by a relief valve which opens under a predetermined pressure, lowering the crushing head and allowing foreign material to pass through without stopping the machine. The crusher discharge opening can then be promptly restored by cutting the feed, to clear the crushing chamber, and raising the head by means of the hydraulic jack. The pressure at which the automatic release operates can be regulated by a convenient valve.

A flexible support between the crusher and its foundation eliminates destructive vibration, facilitates feeding by the gyratory motion at top of crusher, and eliminates need of a massive foundation. Positive lubrication is assured, oil being pumped from a fully enclosed combination storage, cooling and screening tank by means of an electric motor driven unit.

The Type R Crusher is built with cast steel main frame and top shell; heavy forged steel main shaft; extra large bearings; steel gears with machine cut teeth; effective dust seals; and its wearing parts are of heat-treated manganese steel. It has a large self-feeding hopper type three-arm spider; one-piece ground-to-fit head mantle; self-tightening and self-locking concave ring. Top shell and spider are cast integral and readily removed to replace the one-piece concave ring. Lower flange is taper turned to accurately fit the main frame and to facilitate removal for replacement of wearing parts.

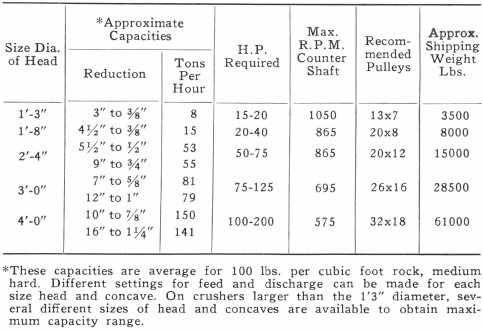

Gyratory Crusher Capacity Table

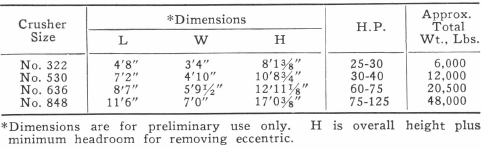

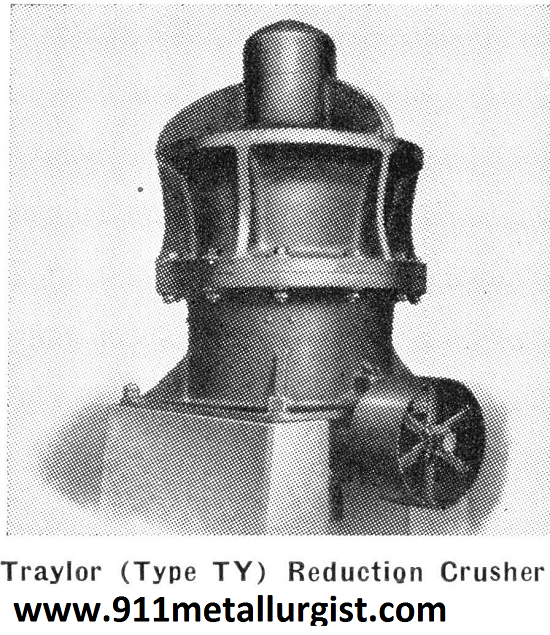

Traylor Reduction Crusher

Traylor (Type TY) Reduction Crusher is compact and of simple design, which provides maximum strength and high efficiency. It occupies minimum floor space, requires little head room and is easily and economically maintained. It is a machine of many exclusive features, among which may be mentioned: an all cast steel frame, with upper shells and spider made in one piece; a ball and socket type spring suspension; non-chokable, self-tightening bell head and curved concave, made of manganese steel; a patented dust seal, an efficient device for excluding dust and grit from the gyratory crusher lubrication chamber; a positive automatic forced feed lubrication system with water cooled oil reservoir; machined cut steel gearing; a self contained counter shaft fitted with roller bearings and automatically lubricated; an all-around bottom discharge, without diaphragm.

For individual requirements and recommendations you should specify the kind of rock to be crushed, the size of the feed, size of the largest rock in the feed, size of product required, the largest and smallest product for which adjustment is to be provided, whether the material is hard, medium or soft, brittle, tough or spongy, dry, damp, sticky or wet, and capacity desired in tons per hour.

Additional data gladly furnished upon request.

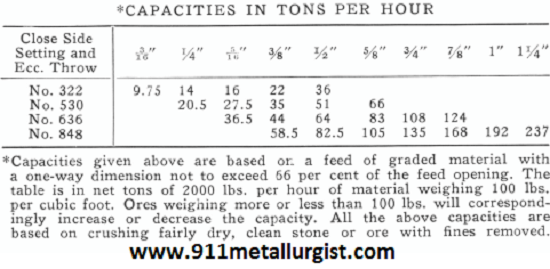

Gyratory Crusher Capacity Table