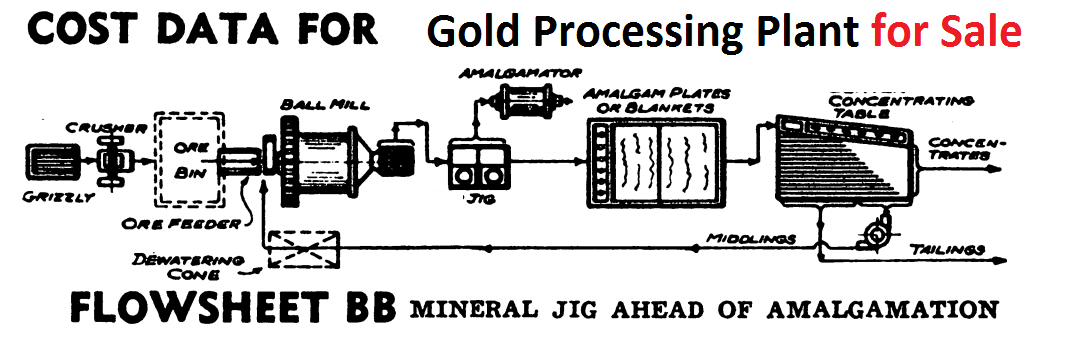

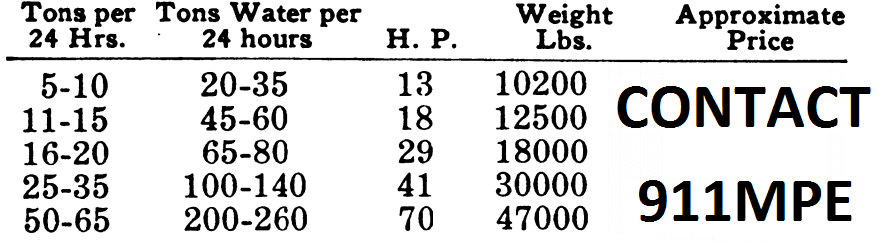

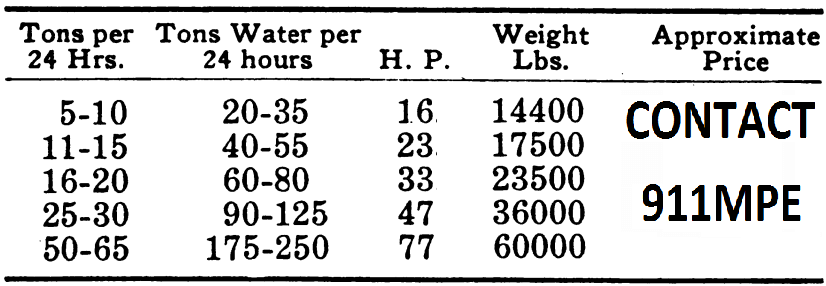

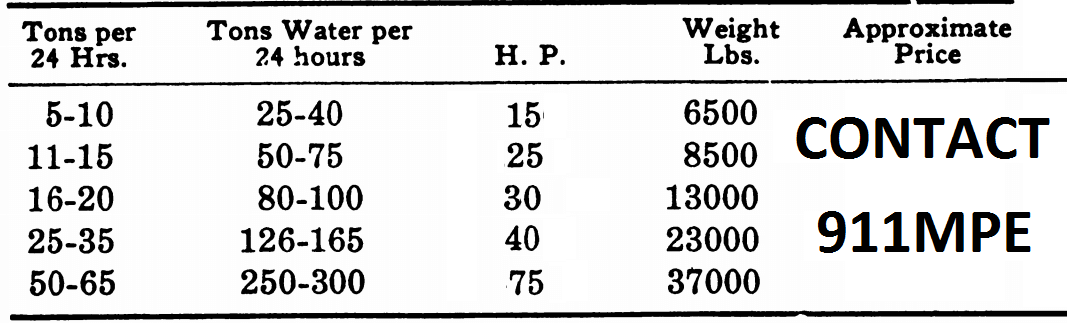

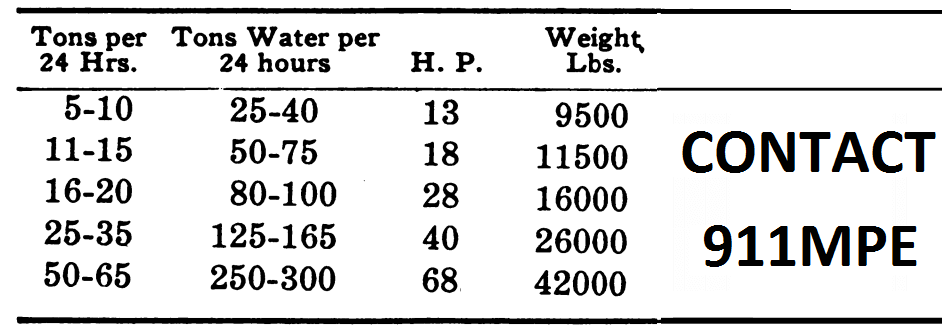

These five illustrated flowsheets fully described in the article “Small Gold Ore Processing Plants” follow a natural sequence. These start with a very simple. Flowsheet AA, and then by the addition of the more extensive equipment, it is possible to take care of slight changes in the ore as well as improve recovery. The following tables include the tonnage handled per day in each mill, the total amount of power required for operation, tons of water needed for milling, weight of machinery and approximate machinery cost for each mill according to the flowsheet utilized. These estimates are based on belt driven machines and are FOB factory. Motor driven equipment costs approximately ten per cent more than belt driven.

This flowsheet is the lowest priced possible and can be used on an ore with a high-percentage of free gold values and where the values are unlocked at reasonably coarse grinding.

Flowsheet BB has a Mineral Jig and Amalgamator in addition to equipment required for Flowsheet AA, and is used for an inexpensive plant where values are coarse but minerals are coated or filmed and will not amalgamate readily on plates. Jig recovers “rusty” values in a high grade concentrate for forced amalgamation treatment in Amalgamator. On these ores, blankets, corduroy or Gold Matting usually are substituted for amalgamation plates and their concentrate also treated in Amalgamator.

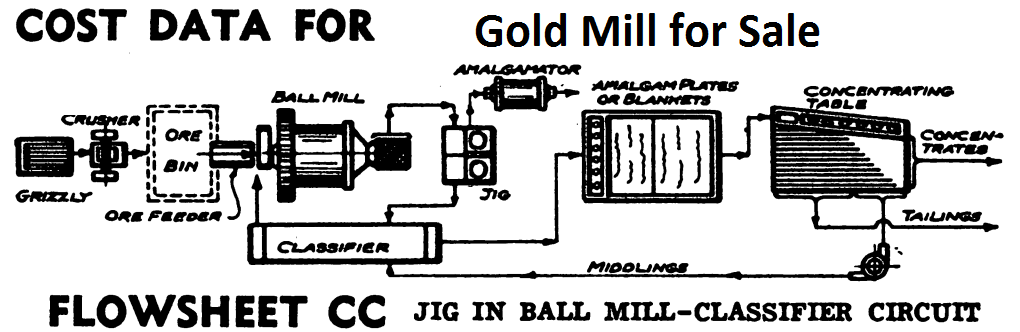

This flowsheet with the addition of the classifier allows finer grinding and the jig used in the closed grinding circuit has increased efficiency. It will give the highest recovery possible for amalgamation and gravity concentration.

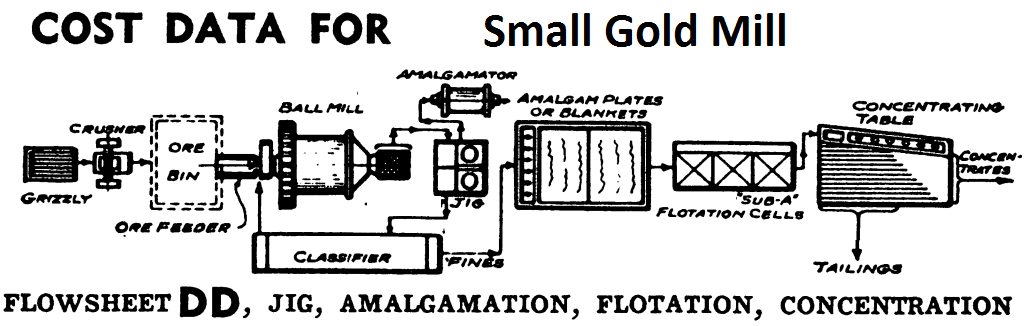

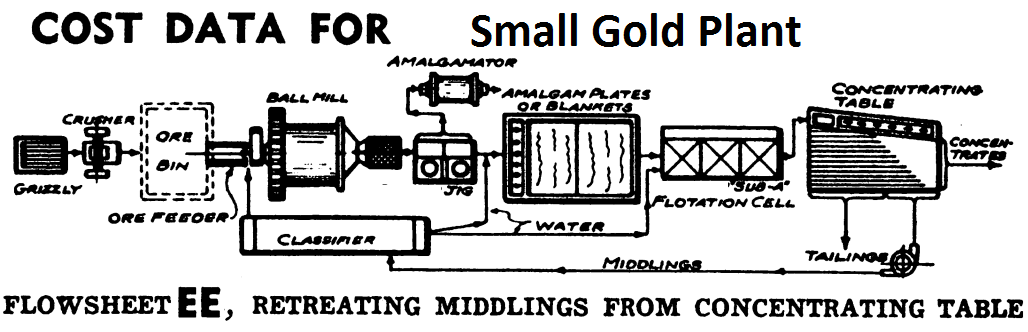

The addition of flotation brings recovery to the highest point as slime values are recovered as well as more granular minerals. Values that can be amalgamated are secured in bullion form and remainder are recovered in flotation concentrate. This flowsheet necessary where minor percentage of values are present as metallics, at commercial fineness of grinding, and where the minerals are friable and easily slimed in fine grinding such as galena or the various telluride minerals.

From the above you will note that the additional cost of the classifier, flotation cells, and reagent feeder, which means so much in these simple Gold Ore Processing Plants, is very small.

mobile ore processing plant