Table of Contents

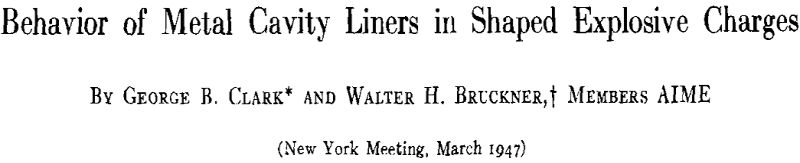

Since the end of World War II interest has been increasing in the use of shaped charges in the mining industry and in other industries using explosives for blasting purposes. Shaped charges employ the principle known as the “Munroe effect,” which was discovered by Charles E. Munroe more than 50 years ago (in 1888). Details of their design have been explained elsewhere.

The following discussion deals with the behavior of the metal in the cavity liners when they are subjected to intense pressures exerted when the explosive charge is detonated. Among the conclusions reached in research on shaped explosive charges, the following have been established concerning cavity liners:

- The optimum wall thickness of a conical cavity liner is dependent upon the apex angle of the cone as well as on the base diameter of the charge. Acute apex angles require thinner walls for optimum performance and more obtuse angles require thicker walls for the same base diameter.

- Cones were more effective in forming a penetrating jet when the walls were tapered; that is, the thickness of the wall of the cone increased from the apex down.

- The physical and mechanical properties of metals have a marked effect upon their performance as cavity-liner material. Boiling point, ductility, malleability, tensile strength, and hardness are among the properties that influence the effectiveness of a metal used as a cavity liner. Lead, for example, makes a wide, flat crater in steel plates. Aluminum makes a deeper crater than lead, and an aluminum alloy having a high tensile strength makes a deeper hole, but slightly smaller in diameter. Cast iron makes a deep, narrow hole.

These findings, together with the following analysis under Metallographic Survey of Slug, offer solutions to many of the problems involved in solving the mechanism of the formation of Munroe jets.

Metallographic Survey of Cast-Iron Slug

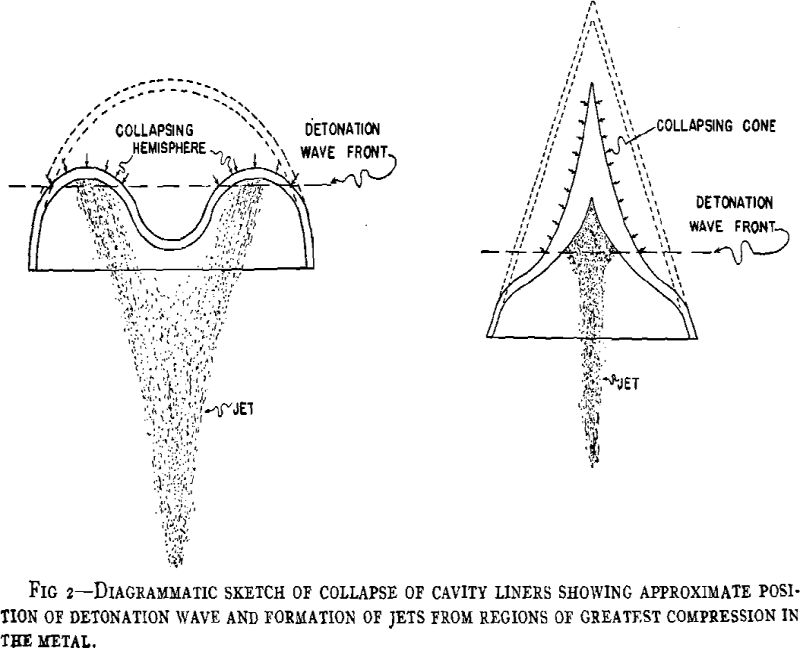

The cast-iron slug was sectioned on a diametral plane through the original axis of the cone.

The extreme ductility exhibited by the interior regions of the slug is unusual for a gray cast-iron composition representative of the cone material. In tension the gray iron is notoriously a material of low strength and brittleness. Under the compressional stress of the shaped charge and the rapid application of the stress, the ductile behavior of the cast iron may have been enhanced by the heat developed internally by friction.

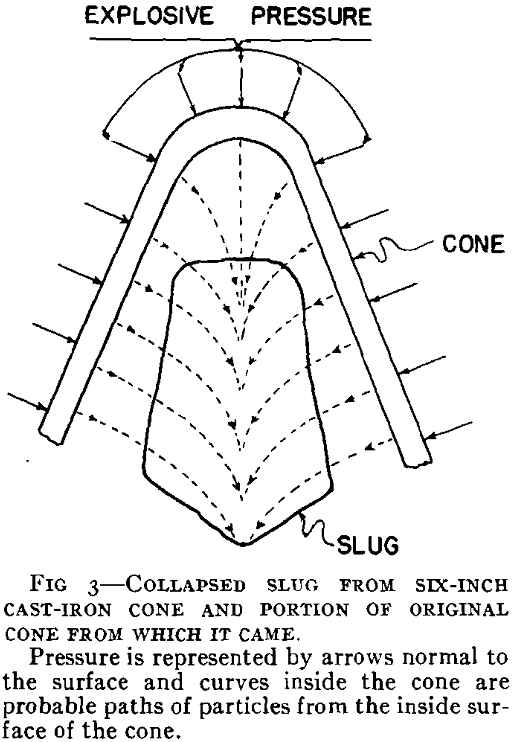

Collapse of Cavity Liner

The kinetic pressure against the outside of a liner is caused by the intense bombardment of molecules of the explosive gases. These molecules probably do not penetrate more than one or two atomic layers into the surface of the metal liner.

Their intense impact pressure, however, causes the wall of the liner to be forced in toward the axis of the cone. A study of the microstructure of the collapsed slug of cast iron shows that the more malleable constituents of the iron have been literally squeezed into a new structure in the direction of the axis of the slug. The total picture of the mechanism of jet formation then must include the effect of the impact of the explosive gases plus the compressive forces set up in the metal. It was concluded that in a cone the grains are in effect acted upon by two sets of compressional forces.

Theory of Jet Formation for Hemispheres

The mechanism of jet formation in hemispherical cavities is not as clearly defined as it is in conical cavities. Slugs from hemispherical charges have not been recovered in complete enough form to enable metallographic studies to be carried out on them. If hemispherical cavity liners are regarded in the same manner as conical cavity liners with reference to the ratio of mass of the jet to the mass of the liner, and the accompanying relationships between pressure, velocity, and energy, the same theory should apply in both cases.

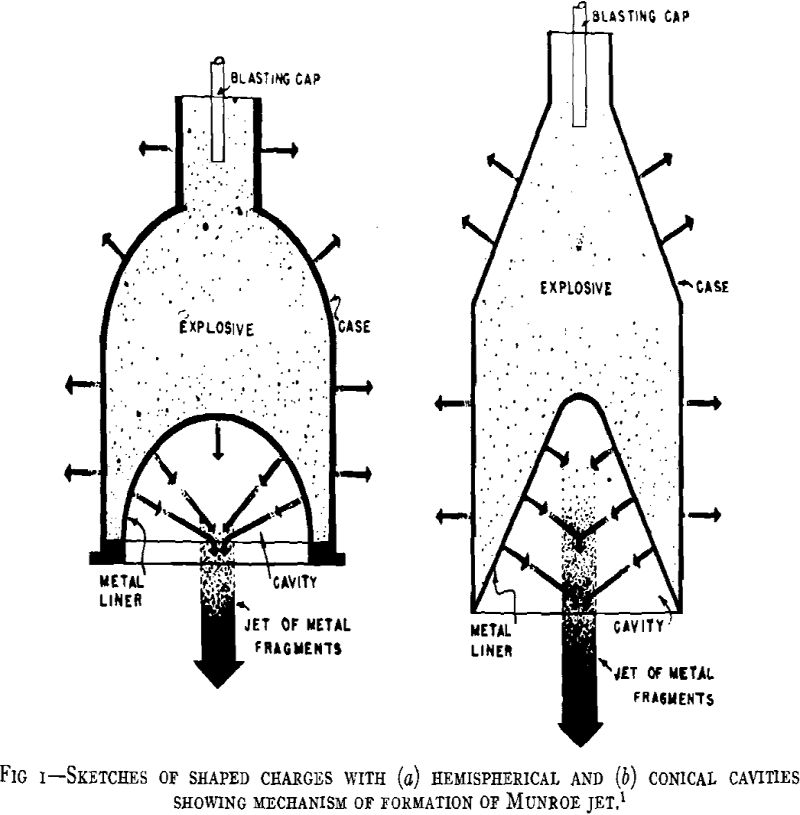

In the case of cones it appears certain that the particles that form the jet are ejected by compressional forces. The same probably is equally true of hemispheres. At the time when the detonation wave strikes a hemisphere, the inside layers at the apex are subject to compressional forces. As collapse proceeds, the region of compressional forces moves down the inside of the liner until collapse is complete (Fig 2). If the liner turns inside out the portions of the metal that were subject to compression are in turn subject to tensional forces. It is from the regions of compression that the jet particles must emerge. The region of compression would be composed of a symmetrical section of the hemisphere, beginning as a point and widening into a larger and larger circle as the process of collapse advances. The particles would then be ejected normal to the surface, which would focus them along the axis of the cavity to form the jet.