In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating variables. These variables are anything that affect the performance of the equipment.

Lets begin with an over view of these two crushing stages. Then describe various flow sheets, and discuss the variables that influenced their design. After the whys have been given we will discuss the equipment and the operating techniques required to operate a modern crushing plant.

The two major variables that determine the size of the crusher and the design of the flow-sheet are the tonnage through put required and the hardness of the ore.

The tonnage will be determined by economic factors, namely what tonnage is required to make the mine profitable? The hardness of the ore is determined by what is known as the WORK INDEX. This measurement is determined by the resistance of the ore to breakage. It is discovered by the energy output required to reduce the ore to a specific predetermined size. It is measured by the KILOWATT PER HOUR usage of electricity required.

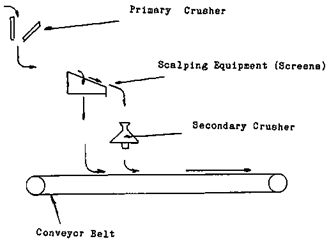

Let’s start with a very simple flow sheet.

This one is designed for very soft rock, or where the product size isn’t important.

The feed comes from the primary crusher and will have a certain amount of rock that doesn’t need further crushing. To run this ore through the crusher will be a waste of energy and crushing space. Ideally it should be removed.

To remove it requires a procedure called “SCALPING”. This is when the ore is allowed to flow over a set of SCREENS or GRIZZLIES. The large ore won’t be able to pass through the mesh, but the fine material will, this effectively separates the two sizes.

The large rock that required further size reduction will be crushed before it is allowed to continue to the next stage of processing.

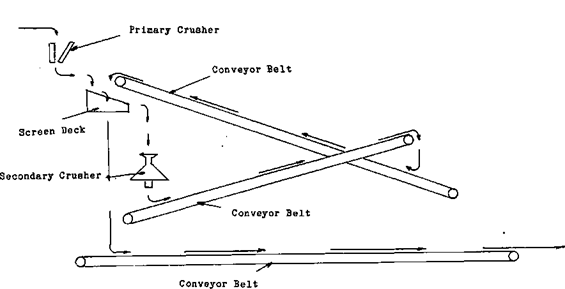

With our second schematic, the flow sheet is practically the same.

The ore is a little harder and the sizing more critical however, this means the positioning of the equipment has to change a little. The ore is still discharged from the primary crusher to the scalping equipment. For this type of application this is usually a screen. Again the fine material is removed from the circuit while the course gets crushed. But now, instead of continuing, the crushed product is directed back to the screen for further sizing. Any rock that isn’t small enough will have to go through the crusher once more. Designing the circuit this way insures that the crushed rock has a uniform size.

Just for interest sake, the first circuit we looked at is called an OPEN CIRCUIT. This is because of the constant forward movement of ore. The second one is referred to as a closed circuit. That is because the ore must meet the circuit’s objective, in this case the correct size, before it is allowed to escape the closed loop of the crushing circuit.

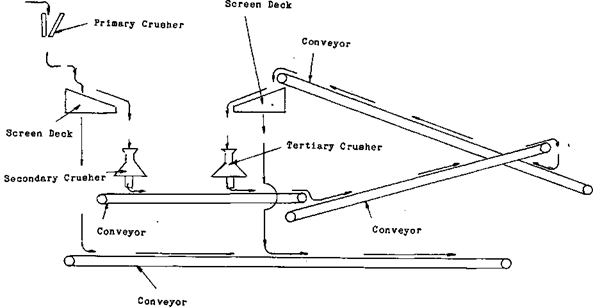

Our last schematic represents a CLOSED CIRCUIT. This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing be done in stages.

Again the ore will come from a Primary crusher and be scalped. The coarse material will be crushed by the secondary crusher. The fines will be taken out of the circuit. Once the secondary has finished with the ore it will be reclassified by a second set of screens with the oversize going to the tertiary crusher. The discharge of the tertiary is reintroduced to the screen deck to ensure that the ore size is uniform.

These three schematics are samples of crushing circuits. There are many other varieties, each one dictated by the requirements of the ore, and the economics involved.

Although each mine has its own individual problems, and the resulting unique design, they do usually have one thing in common. Almost all secondary and tertiary crushing circuits use the same type of crusher, the cone crusher.

Within a secondary and tertiary crushing circuit there are three main types of machinery, CONVEYORS, CRUSHERS, and SIZING EQUIPMENT.