Table of Contents

- A-Z Guide to Screening Ore, Rock & Aggregate

- Vibratory Screen Terminology

- Evaluation of the screening purity

- Factors effecting screening

- EFFECT OF CHARACTERISTICS OF MATERIAL ON SCREENING

- EFFECT OF SCREENING MACHINE ON SCREENING

- EFFECT OF MESH CHARACTERISTICS ON SCREENING

- PURPOSE OF VIBRATING SCREENS

- SCREEN TYPES

- EFFECTS OF SCREENING PARAMETER CHANGE

A-Z Guide to Screening Ore, Rock & Aggregate

A simple definition of a “screen” is a machine with surface(s) used to classify materials by size. Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”.

Knowledge of screening comes mainly from experience. However, through experiment, test facilities and compilation of field data, reliable criteria have been developed by screen manufacturers. This factual data is now tabulated for use in selecting the type and size of screen best suited for the job.

The most common application of a vibrating screen is to separate an unconfined conglomerate of materials into different size fractions. Other popular uses of screens are scalping, washing, dewatering and dedusting. A review of the duty is essential to know the type of screen to recommend. When this is established, the capacity chart is then used to determine the size of unit required.

Nordberg-Lokomo supplies different types of screens, each designed for a specific range of duty. Occasionally there is a choice between the types we offer. In these cases when there is doubt, you can rely on Nordberg-Lokomo experience to help you make the selection.

Vibratory Screen Terminology

COARSE FRACTION Particles which pass over the screen deck,

FINE FRACTION Particles which pass through the screen deck.

SEPARATION SIZE/ SPLIT SIZE Particle size at which feed separates into two products (coarse fraction and fine fraction).

OVERSIZE Material larger than the hole size.

UNDERSIZE Material smaller than the hole size.

HALF SIZE Material smaller than half of the hole size.

SCREENING CAPACITY (Q) Amount of material passing through the screen deck in tonnes/hour

FEEDING CAPACITY Amount of material fed to the screen deck in tonnes/hour

EFFICIENCY OF SCREENING (EFFICIENCY OF UNDERSIZE RECOVERY) Amount of material smaller than the hole size in undersize compared to the total amount of material smaller than the hole size in the feed.

Evaluation of the screening purity

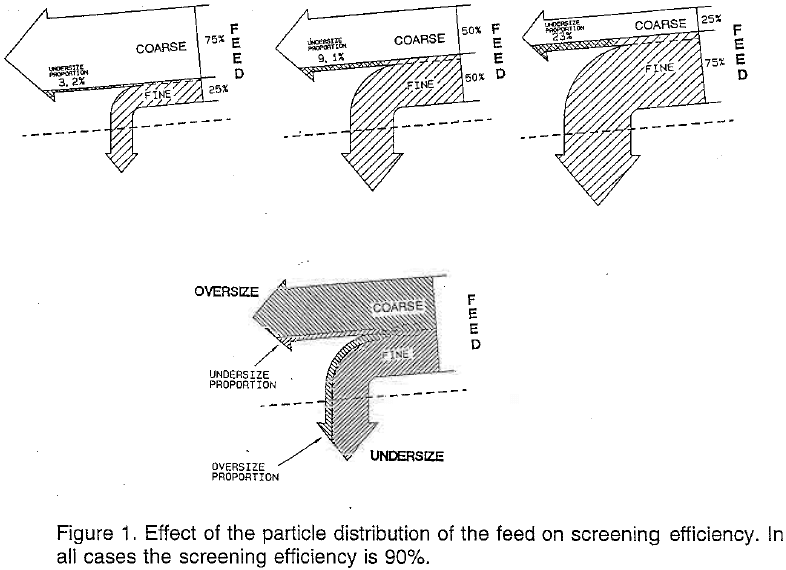

Effect on screening of the particle distribution of the feed

The particle distribution of the feed has an essential impact on purity. See three examples in figure 1. In each one of them the efficiency is 90 %, but the undersize proportion of the coarse fraction varies (3.2 %, 9.1 %, 23 %).

Effect on screening of the chosen screen hole size

When the split size is to be defined either by a wire cloth or rubber element, the hole size for the rubber element must be larger than for the wire cloth element.

Screen Undersize and Oversize proportion

A customer buying screened fraction is interested to know if the material meets quality criteria, of which the undersize and the oversize proportions are the most important.

Factors effecting screening

Factors effecting the screening can roughly be divided into three groups:

– characteristics of material (B, C, F, K, L)

– characteristics of screen (D, E, AF)

– characteristics of screening element (A, G, H, J)

Screening capacity can be described by the following formula with factors specified below:

Qu = A x B x C x D x E x F x G x H x J x K x L x Af, where:

Qu = Screening capacity

[t/h] (passing through)

A = Nominal capacity [(m³/h)/m²] (passing through)

B = Oversize factor

C = Halfsize factor

D = Deck location factor

E = Wet screening factor

F = Material weight [t/m³] (bulk density)

G = Efficiency factor

H = Shape factor for mesh holes

J = Factor for proportion of holes in the mesh

K = Factor for crushed stone and gravel

L = Factor for humidity content

AF = Effective screening area [m²]

The factors are obtained from diagrams based on relationships observed empirically. Since these factors are known, it is consequently possible to calculate the specific capacity of the screen in tons/h per square meter.

EFFECT OF CHARACTERISTICS OF MATERIAL ON SCREENING

There are many factors due to the characteristics of the material, and they have great effects. It is often difficult to determine the total effect.

Effect of oversize proportion on screening

The amount of oversize describes the amount of the particles of the limit size. Particles which are considerably larger than the hole do not make screening difficult. Large stones push stones of limit size through the screening element.

Effect on screening of half size proportion

The quantity of the half size is used to inform / present the quantity of the fine material. Material smaller than half the hole size passes through the screening element very easily. If a feed contains a lot of fine material, it can be fed in large quantities onto a screen. If there is little fine material the screening capacity falls. This is due to the fact that there are a lot of particles of limit/critical size. The throughput of particles of limit size (0.5 – 1.0 x hole) is very poor.

Effect of material weight on screening

Screening capacity depends on material volume.

Effect of particle shape on screening

Uncrushed natural stone is mostly rather round and even. Natural stone is easy to screen.

Crushed stone is angular and rough. Crushed stone is more difficult to screen than natural stone.

Flaky (thickness is small, relative to the other two dimensions) and elongated (length is larger than other two dimensions) stones are the most difficult to screen. They pass over the screen deck laying on their widest side. At worst they become wedged in holes and thus block the whole screen deck.

It also should be taken into consideration that flaky and elongated stones cause differences between normal screening and test screening.

Effect of material humidity on screening

Humidity has the greatest effect on the screening of fine material when the hole size is approx. 16 mm or smaller. The effect gets smaller with larger hole sizes.

Due to the surface tension of water the finest particles adher to the surface of the larger particles and are carried to the wrong fractions.

In the feed contains clay, limestone etc., the screening element may become blocked at the worst, and screening is impossible.

In a feed humidity is mainly fixed to the fine material. The percentage of moisture, therefore, should always be measured in the finest fractions.

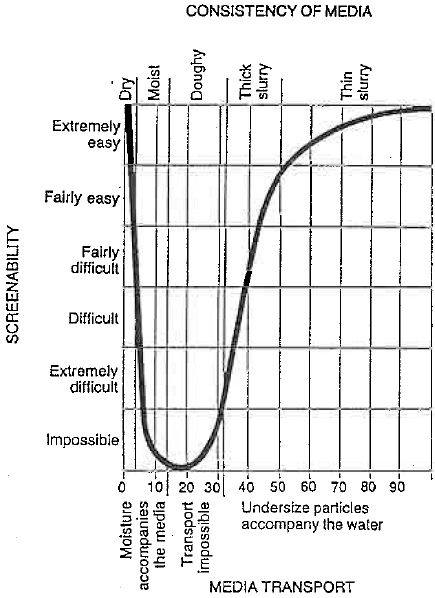

When the humidity is under 3 % it has no significant importance. The problems start at 4 – 5 %. At 9 – 30 % screening is very difficult. When there is more water the screening gets easier, and it is close to separation of water screening.

Fig. 2 Effect of humidity on screening. The curve shows approximate averages which are raised or lowered depending on whether rough or fine material is screened.

Fig. 2 Effect of humidity on screening. The curve shows approximate averages which are raised or lowered depending on whether rough or fine material is screened.

EFFECT OF SCREENING MACHINE ON SCREENING

Stroke length and material amplitude height

Stroke length, rotation speed, stroke angle, and screen inclination form together parameters which affect the operation of the screen. These fundamental factors have to be in proportion to each other.

Stroke length and material amplitude have an effect on:

– how the feeder material starts to separate in the feed box and on the screen element. Separation and blending of the material bed are effective with a long stroke.

– how the holes of the element stay unblocked. If the stroke length is too small also the material amplitude stays too small and the element gets blocked. The problem arises when the hole size is large (50 mm or more).

In practice, the stroke used in a horizontal screen is 7 – 20 mm. A small stroke can be used when screening with a small hole size. Because of mixing and separation, a large stroke is recommended.

Stroke is defined by the swinging mass and the flywheel moment of the vibration unit. Rotation speed has no visible effect on the stroke.

Rotation speed and acceleration

Acceleration of the screen box can be calculated by the stroke and rotation speed. When stroke angle and inclination are taken into the calculation, the vertical acceleration can be found. Vertical acceleration has an effect on the screening efficiency and the rate of travel.

Acceleration should be 4.5-5.5 x G (G=9.81m/s²) with horizontal screens to reach a good screening result. To avoid structural damage for the screening unit, no acceleration greater than 6-7 times G are allowed.

Stroke angle

Stroke angle has an effect on the material amplitude and the rate of travel. The most suitable stroke angle for horizontal screens is 55-60 degrees. Too upright a position can reduce the rate of travel. Horizontal stroke angle can improve the rate of travel but reduce screening efficiency. It also increases the wear rate of the mesh.

Surface inclination

Speed of travel can be increased by inclining the screening surface. If the surface is greatly inclined, the stroke must be short to prevent material sliding over the mesh too quickly. Inclination of the surface can keep the mesh holes open more easily.

Speed of travel

Speed of travel has an effect on screening efficiency and capacity. Increasing the speed of travel can lower the bed of material and improve the screening efficiency.

Length and width of the screen

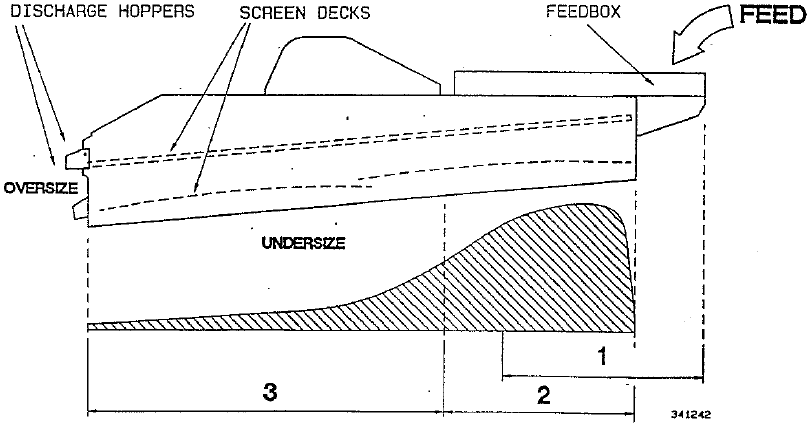

Phases of screening are:

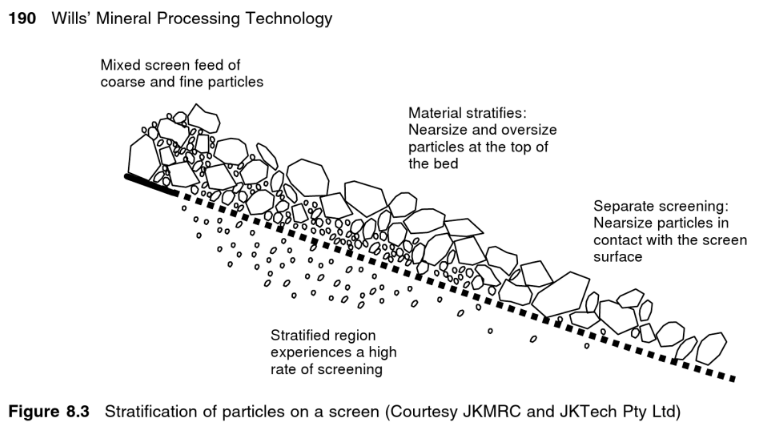

– stratification on the feedplate

– extraction of fines at the beginning of the screening surface

– separation of the wanted fraction at the end of the surface

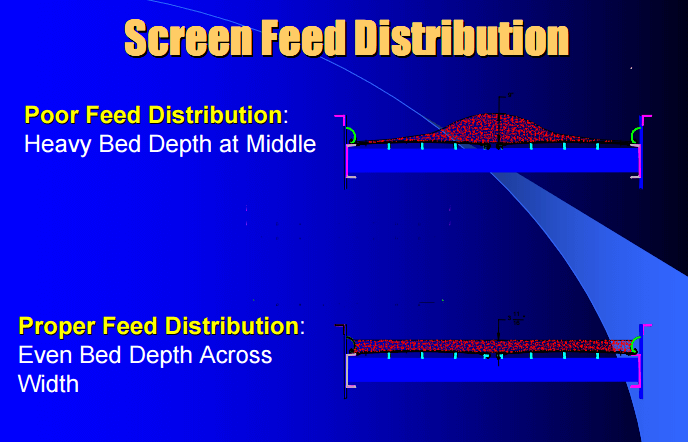

The bed of material may not exceed a height more than 3-5 times the size of the mesh hole on the discharge side of the screening surface. A higher bed of material will reduce the screening efficiency. Feeding capacity for each mesh size depends on the width of the screen. To get efficient screening results the depth of material bed must be at least 2 times the mesh hole diameter on the end side of the surface. Then volume of oversize will determine the width of the screen.

The depth of material bed should be within allowable limits on the beginning and the end of the surface when choosing the screen. Screening area is not the only dominant parameter while choosing the screen. In practice the length is 2- 3 times the width.

Deck factor

A deck factor should be used when calculating lower decks in muitideck screens. In lower decks the feed drops not only at the beginning of the deck, but also later in the direction of the flow. That is why material close to separation size will not be screened out.

Effective screening area

Effective screening area is the area where material can drop down through the surface. Effective surface area is about 0.7-0.9 times the whole area. The whole area is determined by the inside parameters of the screening unit: length times width.

Screening methodology

Screening methodology means screen washing in this context. Water usage in screen washing increases the fines throughput.

Figure 3. Schematic diagram showing how the screening effect varies along the screen deck. Stratification takes place within zone 1, screening of fine undersize particles (75% of the size of the screen apertures) takes place within zone 2 and screening of “critical” undersize particles, i.e. particles of a size close to the size of the screen apertures, takes place within zone 3.

Figure 3. Schematic diagram showing how the screening effect varies along the screen deck. Stratification takes place within zone 1, screening of fine undersize particles (75% of the size of the screen apertures) takes place within zone 2 and screening of “critical” undersize particles, i.e. particles of a size close to the size of the screen apertures, takes place within zone 3.

EFFECT OF MESH CHARACTERISTICS ON SCREENING

Hole size of the mesh

Hole size of the mesh determines the separation size and the sizes of screened particles. Material throughput depends on the size of the hole.

Nominal screening capacity

Nominal screening capacity means the amount of material which goes through the mesh with a specific mesh hole size in time and area units. [(m³/h) / m²]

Efficiency

The amount of loading influences screening efficiency. In practice it is impossible to reach 100% efficiency. Maximum efficiency is about 95%. In most of the cases 90% is achieved and the screen can be said to be under 100% loading.

Shape of the mesh hole

A square hole is the usual shape. A round hole is more difficult to pass through and an elongated hole passes material more easily.

Free surface of the mesh

The greater the open area of the mesh, the more effective is the throughput. When determining the open area of the mesh, the diameter of the wire between holes in different meshes differs, and has to be taken into consideration.

Type of the mesh

The type of the mesh will have an effect on screening efficiency. The most significant difference will be in special screening cases. For example while screening elongated material, mesh should be of the vibrating type (rubber or harpmesh)

PURPOSE OF VIBRATING SCREENS

Screens are used mainly for the following purposes:

Scalping

By scalping it is meant screening of coarse material in order to remove the undersize, typically before a primary crusher. Because of the coarse feed the top deck, which may be the only one, is often of a grizzly type. i.e. grizzly bars as opposed to mesh. This type of screening calls for a robust construction whilst there is no requirement for screening efficiency.

Feeding of a crusher

There would not be a particular requirement for screening efficiency on this duty, unless the screen is also used for final sizing as is often required in a two stage operation.

Final screening into various fraction sizes

For final screening there is always a requirement for product quality, which may vary.

SCREEN TYPES

Leaving out the ancient trommel screens, stationary grids, and similar types, the following means are used to make the screen vibrate. All screens today are vibrated by various methods to pass the undersize through the apertures of the screen mesh or grizzly bars.

Freely vibrating screens

By freely vibrating screens one means screens that are supported on springs, and the box is vibrated by a vibrating mechanism (also called an exciter) which vibrates the screen box in various ways, depending on the type of vibrating unit.

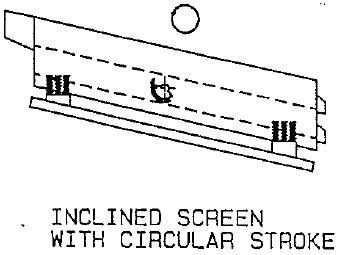

Circular motion

Screens with a circular motion are the most common type. The vibration is circular because of a single eccentric shaft mechanism. This movement would not move the material forward, unless the screen is inclined in the direction of the material flow. This in turn means that the screening efficiency is not quite as good as a horizontal screen. The capacity as such is often higher as this screen is able to transport the material more quickly. The higher the inclination, the greater the transport ability. Inclination is typically 12° – 20°. The inclination also helps to prevent pegging.

The depth of this material layer is more critical with a circular motion screen than with a horizontal screen. The inclination reduces screening efficiency.

This type of screen may be used for almost any application. They are also cheaper to produce.

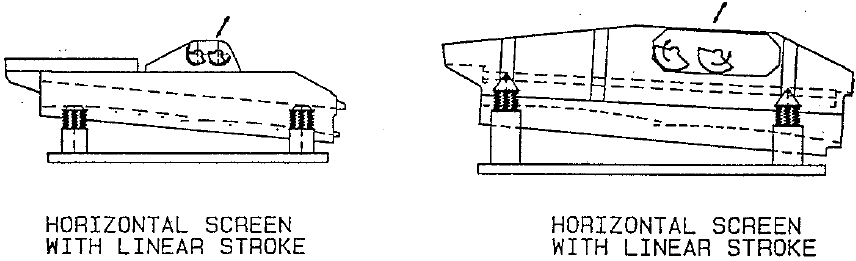

Linear motion

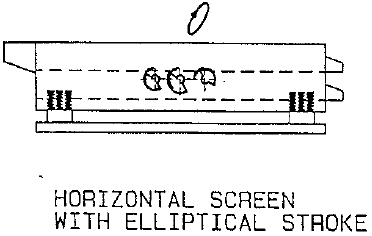

The vibration of this type screen is created by two eccentric shafts, rotating in opposite directions. This gives the box a linear motion. The stroke angle would depend on the relation of the eccentric weights of the two shafts to each other. Because of the linear stroke the material is moved in the direction of the stroke and the screen may be installed horizontally. That is why they are often called horizontal screens. The inclination would be typically 0° – 5°.

The horizontal screen gives high screening efficiency, and they are often used for final and fine screening. Another advantage over inclined screens is their lower profile and therefore, horizontal screens mean lower structures and buildings, and shorter conveyors.

Elliptic motion

Elliptical motion can be achieved by various means. One method is by using three eccentric shafts, two of which would create the long axis and the third, the short one. These screens are used in special applications where the aim is to gain advantages of both circular and linear motion screens. It is a compromise however, there would also be a measure of disadvantages. These screens are typically installed at an 0 – 5° angle.

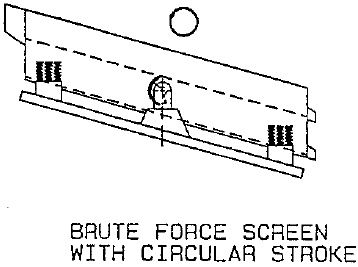

Brute force screens

The eccentric shaft(s) of this screen type are connected both to the screen box and the foundation. The two shaft type would give a circular motion whilst the single shaft type would give this near the vibrating unit, and differ with the loading, depending on the action at each end.

These screens are used mainly for screening coarse material. The screens become heavy, and the dynamic forces which the foundation has to absorb, are a disadvantage. Brute force screens are installed 12° – 20° inclined.

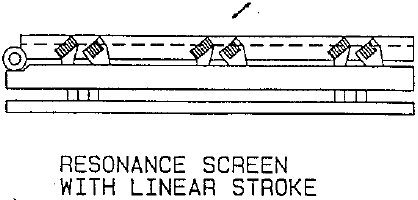

Resonance screens

The vibration of this type of screen is created by the resonance between the under-frame and the screen box or decks, and because of the resonance little energy is needed to vibrate the box. These screens are always installed horizontally.

The advantage of this type is the high efficiency as the screen can be very long, and therefore are mainly used for fine screening. They also have a low profile which can be advantageous. However they have very heavy and expensive structures.

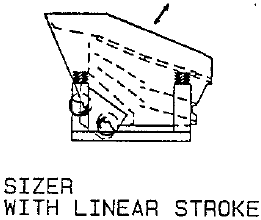

Sizers

Sizers are generally small and equipped with multi decks to assist screening. The products of two or more decks are often blended in the chute work of the screen. They have very high capacity because of the inclination. The apertures of the meshes need to be considerably larger than the cut, and thus affect the efficiency. This is compensated for by the blending.

The advantage of this type is that it can be used for difficult material with less blinding than with other types.

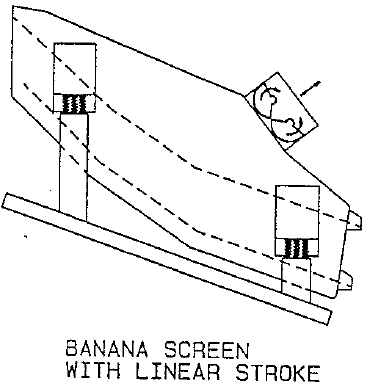

Banana screens

Banana screens are, as the name implies, “banana” shaped. This contributes to the even loading of the screen mesh and lowers the material depth at the feed end.

The steep angle at the feed end gives the material a high velocity, some 3 – 4 m/s. Later the angle levels out and slows down the material to 1 – 1.5 m/s in the middle and 0.5 – 0.8 m/s at the discharge end. This is where the screening efficiency is achieved.

These screens are generally large and used in high tonnage plants, particularly in mining where fewer fractions are separated.

Special screens

There are a number of special screens, of which the “flip flop” is an example.

The special narrow rubber mesh strips are installed perpendicularly between two separate frames. The meshes being attached to one frame on one side and to the other at the other side the bulk receives extremely high accelerations.

This helps screening of wet, dirty and other difficult materials.

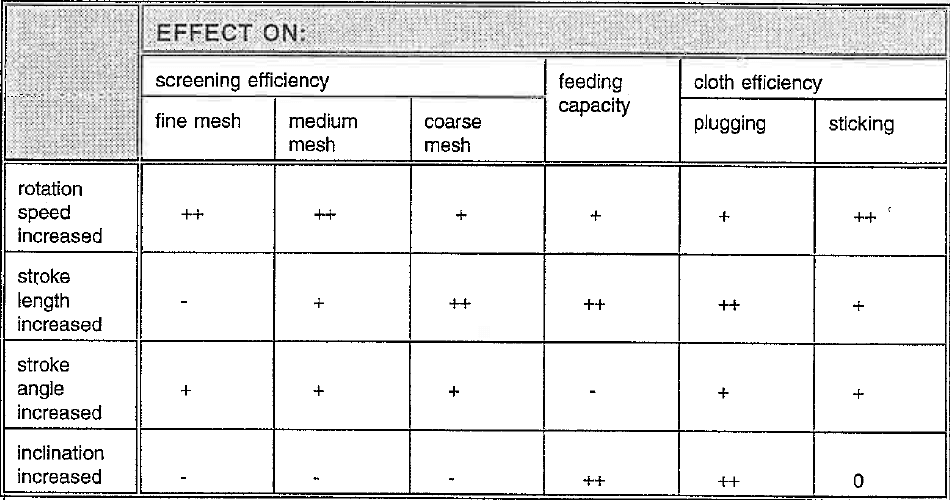

EFFECTS OF SCREENING PARAMETER CHANGE

This table is a guide only to the parameters of a horizontal screen. When solving screening problems, take also into account the size parameters of the material, screen cloths and physical screening conditions.

This table is indicative only, and is based on standard parameters under normal operating conditions. For special conditions contact the manufacturer.

++ very favourable effect

+ favourable effect

– unfavourable effect

0 no remarkable effect

NOTE:

When changing screening parameters the maximum permitted acceleration and rotation speed must not be exceeded.

https://www.911metallurgist.com/what-is-the-capacity-of-vibrating-screen-per-area