Dewatering of the fine clean coal fraction, — 28 mesh (595 microns) represents one of the most difficult and costly separations in typical plant circuits. Since 1969, the Screen Bowl Centrifuge has offered an economical alternative to filtration/thermal dryer combinations. The performance of Screen Bowl Centrifuges has been continuously modified and improved to dewater not only coarser coals, but also today’s variety of ultrafine material. Actual test comparisons with alternative methods show the Screen Bowl Centrifuge to be most cost effective and efficient when all factors are considered.

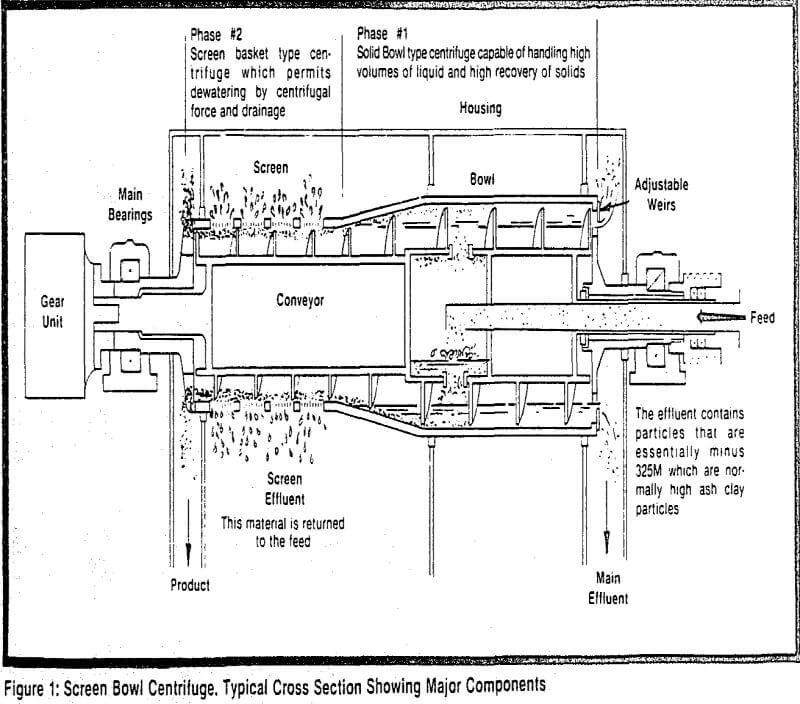

The feed slurry is introduced through a stationary feed pipe and is brought up to full rotational speed in an acceleration chamber. The slurry is distributed through feed ports to the inner diameter of the Solid Bowl cylinder section. The higher specific gravity solids settle against the bowl wall due to the increased centrifugal forces with the liquid migrating toward the axis of rotation.

Once this initial separation has taken place, a helical screw conveyor, operating at a slightly lower speed, advances the solids towards the screen section of the machine. The rate of advancement is controlled by 1) a mechanical gear reducer, which provides a fixed ratio differential, 2) rotational speed, and 3) conveyor pitch. At some point, depending on the liquid level controlled inside the machine, the solids emerge from the slurry. The partially dewatered solids continue towards the screen section while the clarified liquid overflows at the effluent end of the machine.

With the development of modern coal preparation technology and an increased emphasis on fines recovery. Screen Bowl Centrifuge designs were modified and improved. The earlier machines offered length to diameter ratios which limited clarification capabilities. They were well designed to handle bulk solids but could not effectively recover ultrafine material. Second generation units substantially increased clarification through improvements in the geometrical design configuration coupled with higher speed capabilities. The concept of bulk solids classification has been replaced by efficient one-step recovery and dewatering.

On the early designs, high maintenance costs and onstream reliability were major concerns. Up to this point, the Centrifuge application in coal had been successful from a process standpoint but proved to be extremely expensive to operate. The hardfacing technology clearly was insufficient to address the levels of abrasion associated with the required rotational speeds. It became evident that improved wear resistant materials were needed to increase the life of components subjected to abrasion.

Large diameter Screen Bowl Centrifuges have been chosen as the primary dewatering units in proposed coal slurry pipelines. Detailed test programs, performed initially on small scale equipment and later confirmed with full-size production units, have demonstrated the viability of the Centrifuge circuit.