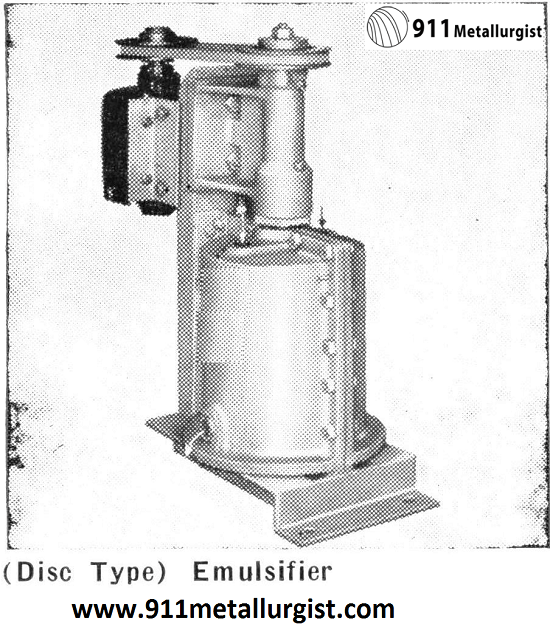

The (Disc Type) Reagent Emulsifier is used to emulsify flotation reagents with water before introducing them into the cells. By using this unit greater efficiency is attained from reagents, decreasing the amount necessary to produce the best flotation results.

The unit consists of a sturdily constructed tank and impeller, together with the driving motor, on a strong mounting bracket. The impeller shaft has a series of disc shaped vanes which rotate between stationary beaters welded to the sides of the emulsifier tank. The violent stirring action thus produced completely emulsifies the reagents before discharging them.

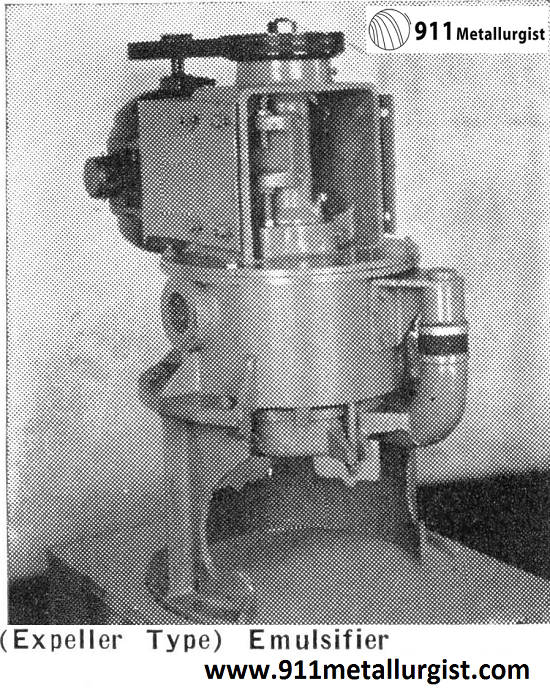

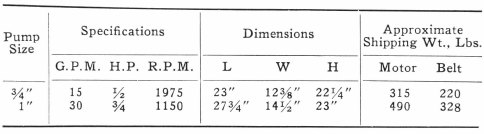

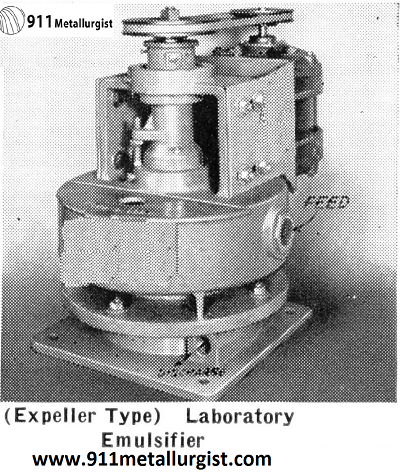

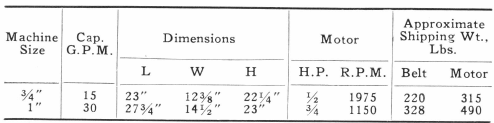

Expeller Type Reagent Emulsifier

Many operating plants in the field and tests performed in our own laboratory, have definitely proved that the ¾” and the 1″ Vertical Sand Pumps are excellent reagent emulsifiers.

The water insoluble reagent is fed full strength to the pump bowl together with the desired amount of water and any other reagents. The pump discharge is remarkably well emulsified with the complete dispersion of the reagent in the solution, resulting in a considerable saving in reagent consumption. If a still further degree of emulsification is desired, the discharge of one emulsifying pump can be pumped directly to the bowl of a second unit.

The Vertical Sand Pump is ideal for this purpose because it will handle very small tonnage rates. Exceptional wearing life is obtained by this unit as an emulsifier due to the fact that there are no bearings or stuffing boxes exposed to contact with the reagents.