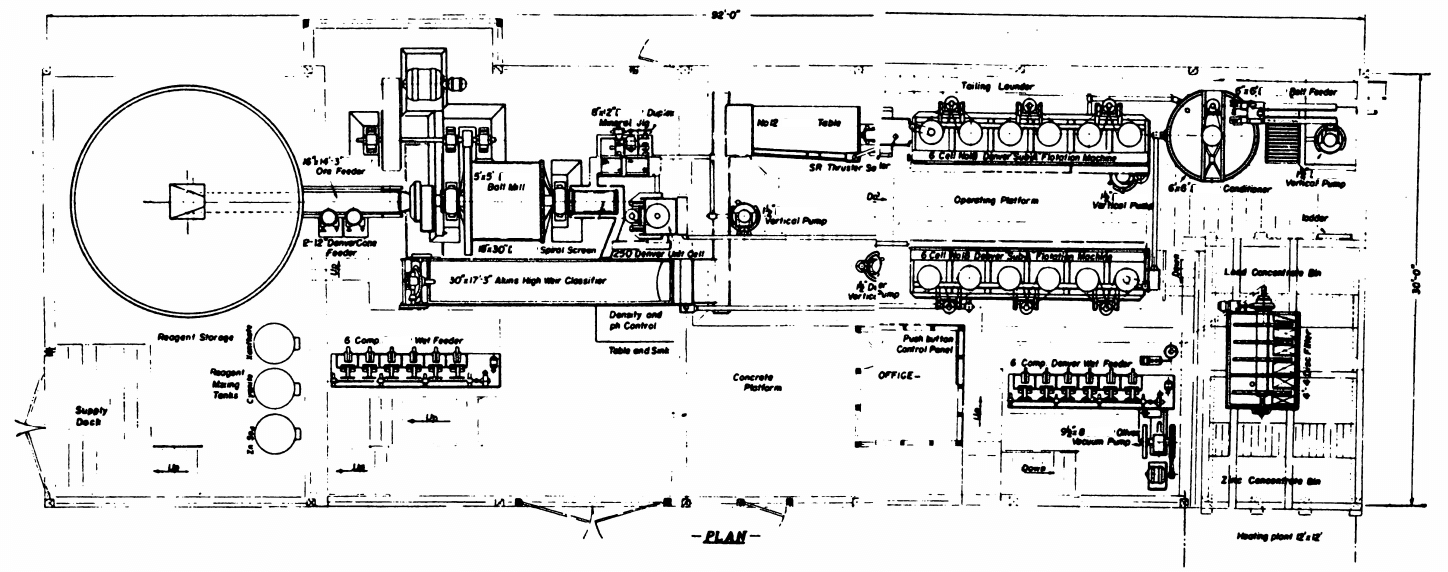

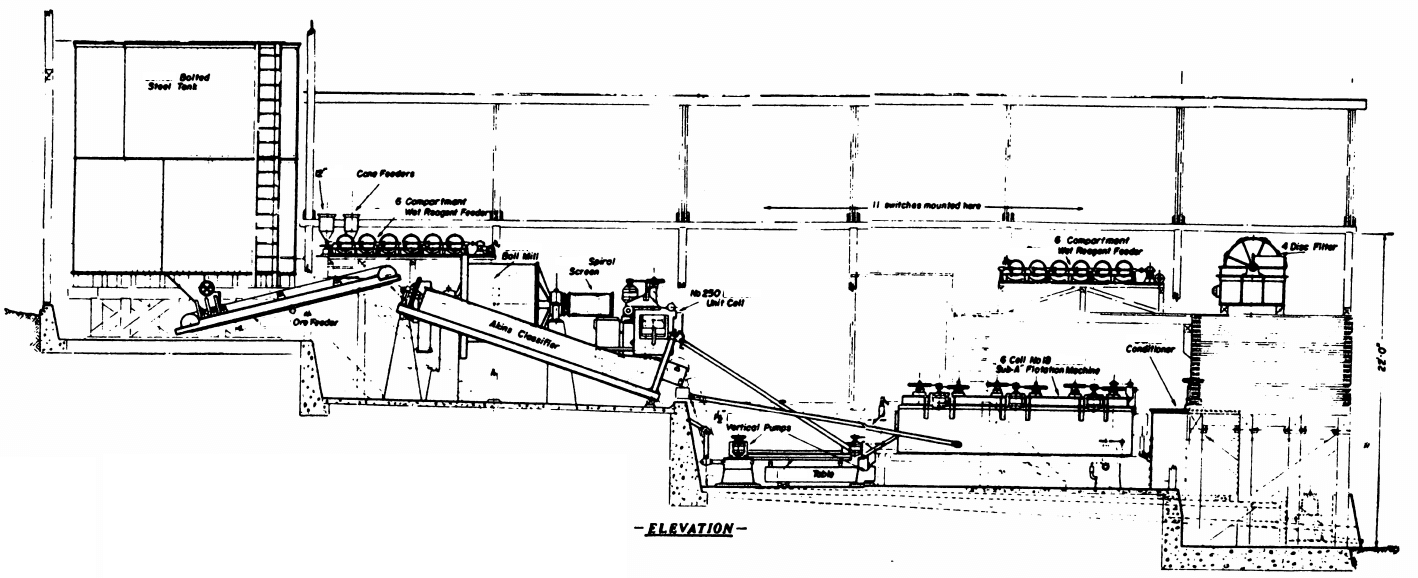

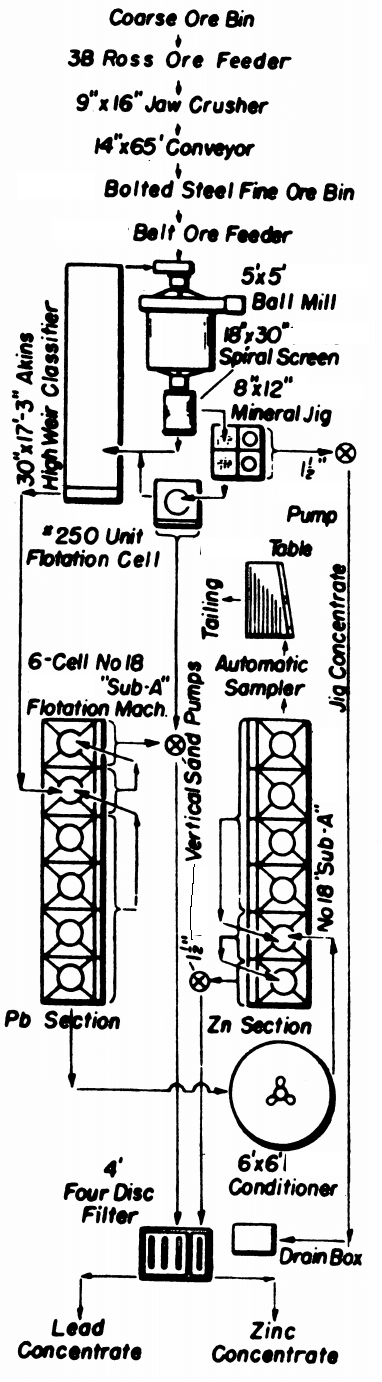

Here is an example process equipment list you’d need to build a small 50 TPD flotation plant to recover metals like copper, lead, zinc or even nickel and most sulphides be froth flotation.

|

Process Plant Equipment |

Approximate Motor H.P. |

|

Crusher 10 x 16 |

20 |

|

Fine Ore Bin |

|

|

Belt Ore Feeder 20″ x 10″ |

2 |

|

Ball Mill 5′ x 5′ |

50 |

|

Duplex Mineral Jig 8″ x 12″ |

1 |

|

Spiral Classifier 30″ x 16′ x 9″ |

2 |

|

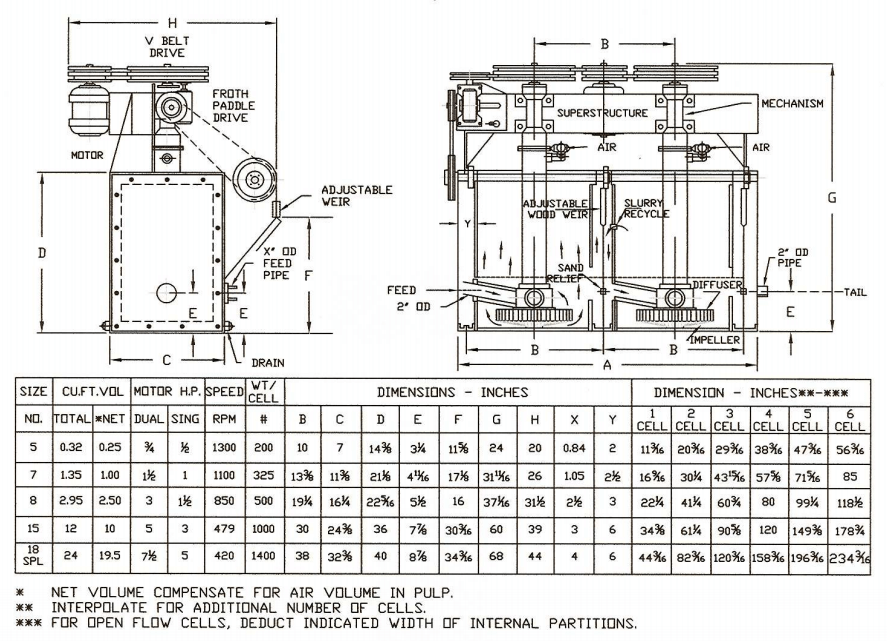

8 Cell x 24 CuFt Flotation Cells |

20 |

|

Reagent Feeders |

0.5 |

|

Sampler |

0.5 |

|

Disc Filter—4′ x 3′ Disc |

1 |

|

Vacuum Equipment |

9 |

|

Mill Water Tank |

|

|

Sand and Water Pumps |

5 |

Construction Items to Consider

when planning and costing a installation of a 50 Tons Per Day TPD Flotation Plant and all its Process Equipment

- Roads and Clearing Site

- Excavation 250 Cu. Yards Rock and Dirt

- Foundations—45 Cu. Yards Concrete—

*Materials Only - Buildings and Foundations

*Laborers—2,750 Hours

*Carpenters and Millwrights—

**1,350 Hours

*Lumber and Hardware

*Glass Windows

*Roofing—Mill Sides and Roof - Machinery F.O.B. Factory

*Freight and Haulage - Electrical Switches and Wiring—

*Materials - Machinery Installation, and Wiring Labor—

*1,450 Hours - Designing, Testing and Supervision—

*680 Hours

Mill operation and costs vary so widely that it is possible, in this section, to give you only a limited amount of information which is intended for rough approximations. Plant location, local labor conditions, distance from sources of supply and markets are all factors which must be taken into account in predicting and establishing milling costs.

General information presented in this and the foregoing sections represents a composite of many actual operations. We hope it will be able to serve you by furnishing a basis for rough estimates so essential for planning long-range profitable milling.

https://www.911metallurgist.com/mobile-ore-processing-beneficiation-plant