Table of Contents

The cleaning of coal by the use of jigs is one of the oldest methods of separating coal from its impurities. Although in many situations jigs have been replaced by other methods, by far the largest percentage of coal today is still being cleaned by some form of jigs.

Description of the Batac Jig

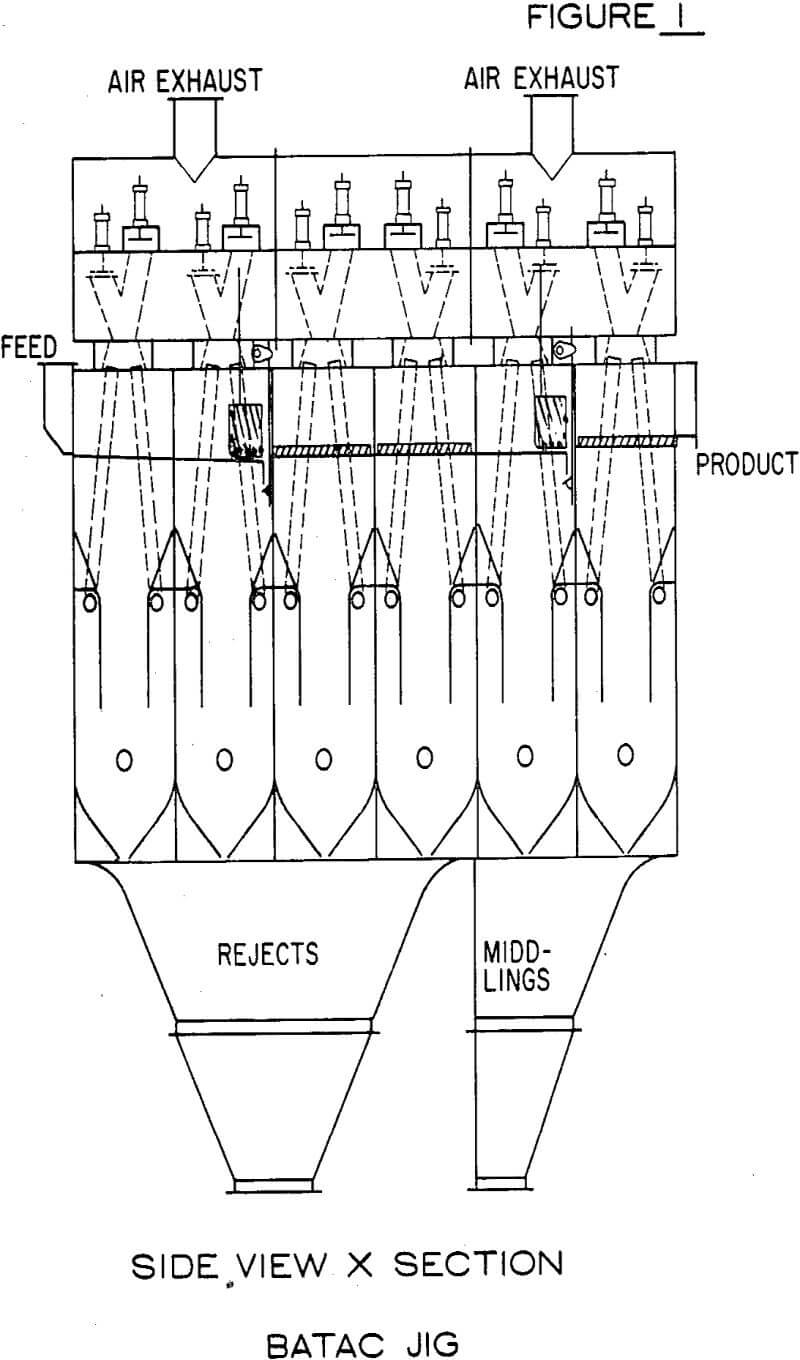

In the Batac, the pneumatically pulsated principles of the Baum jig are still used; however, the method of air distribution has been changed, the pulsations of the air causing the jigging action have been greatly improved by new compressed air valves electronically controlled, and the bed stratification level operated by the reject ejectors is more precisely controlled by inductive-hydraulic apparatus.

In the Baum jig, air under pressure is forced into a large air chamber on one side of the jig vessel causing pulsations and suction to the jig water, which in turn cause pulsations and suction through the screen plates upon which the raw coal is fed. The distribution of this force, being on one side of the jig, tends to cause unequal force along the width of the jig screen area and, therefore, tends to cause unequal stratification and some loss in the efficiency of separation of the coal from its heavier impurities.

The Batac jig can treat coarse as well as fine sizes of coal. In other words, it can handle any of the sizes now being washed in the various types of Baum jigs installed in this country.

The standard Baum jig uses either plunger-type air valves or rotary valves. The Batac jig uses flat discs which are electronically and pneumatically controlled. These valves, both for inlet and outlet of air, can be infinitely varied as to speed and stroke, thus accurately controlling the speed, length and cycle characteristics of the pulsations and suction. The ability to vary the cycle and characteristics of the air operation is of prime importance and is one of the major factors in the Batac performance. Longer pulsation and shorter suction or vice versa are of immense value in opening and closing the bed and obtaining proper stratification. The air valve characteristics are automatically controlled from an electronic solid-state instrument panel, which can be installed remotely in the plant control center.

A Batac jig of this size will require the following:

- Water requirements: 5,300 gallons per minute at 12 psi for the underwater and water with the feed, the latter being generally about one-third of the requirement.

- Operating air: 130 m³ or 4,590 cfm at 7 psi.

- Compressed air for controls: 2 m³ or 70 cfm at 88 psi.

Performance of the Batac Jig

The performance of the Batac jig has been well proven in Germany and other parts of the world. In terms of efficiency and sharpness of separation, it is equal to or better than other coal washing processes in specific gravity ranges above 1.45, except in comparison with heavy-media processes using magnetite. However, even in comparison with heavy media, it may do a comparatively efficient job at separating densities of 1.55 and above.

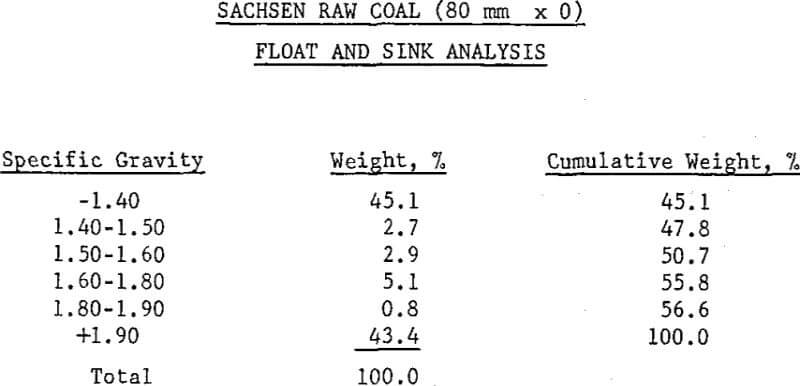

The reasons for presenting the latter are that it gives an insight as to what can be expected in treating an American coal. This particular coal is being prepared for the steam coal market, and sulfur reduction as well as high efficiency is of prime consideration.

Since, in most coal washing processes, the performance of the equipment is shown cleaning down to ½ mm or 28 mesh size and the 28 mesh x 0 is cleaned by froth flotation if at all the data presented in this paper first show the performance at ½”-28 mesh- Data are also presented showing the cleaning performance for the 28 mesh-100 mesh sizes, thus results can be calculated for ½” x 100 mesh. In this way, comparison can be made with other cleaning devices, which also do some cleaning down to this fine size.