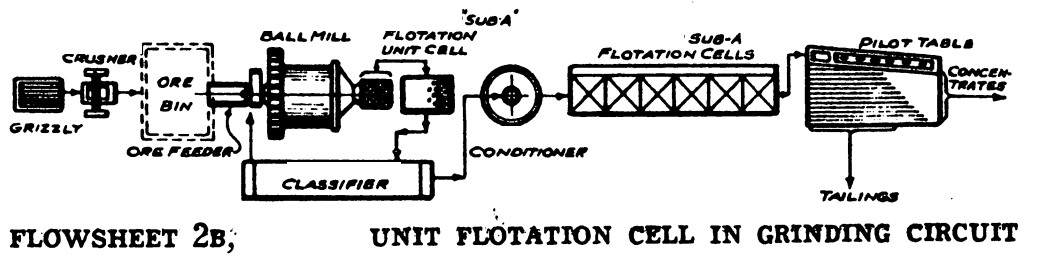

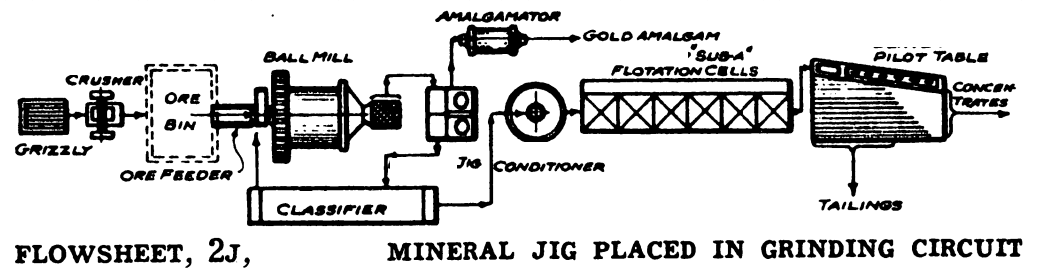

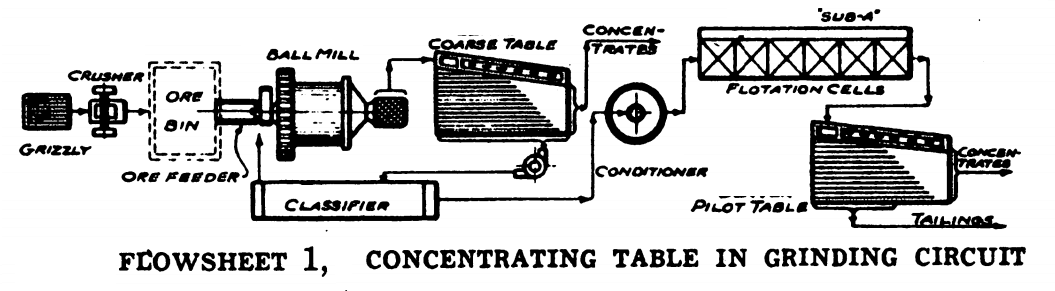

These 5 following estimates on flotation mills cover standard practice as used on base metal and non-metallic ores where the majority of values are recoverable by flotation, and where there is sufficient freed mineral in the ball mill discharge to warrant recovery by means of process Equipment like either a Unit Flash Flotation Cell, a concentrating table, or a jig, in the ball mill-classifier circuit. Many gold and silver ores come under this same classification as not enough of the precious metals are present as free metallics to warrant the use of amalgamation. On lead copper ores, the unit flotation cell is recommended, whereas with free gold ores containing coarse metallic gold values, along with sulphides, we recommend Equipment like a Mineral Jig. No elevator or pump is necessary in this circuit when using the unit cell or jig, such as is the case when the table is placed between the ball mill and classifier. Care must be taken when using a table in not permitting the use of too much water in the circuit to interfere with subsequent treatment, therefore the Unit Flash Flotation Cell or Mineral Jig is economical to install and more efficient.

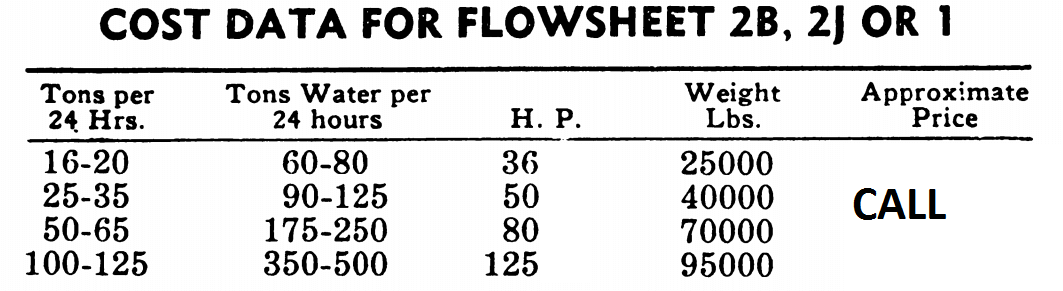

Flowsheets 2B (unit cell), 2J (jig) and 1 (table), with either the unit flotation cell, the jig, or the table between the ball mill and classifier, makes the standard flotation mill. The data below is for all equipment necessary and with either unit flotation cell, jig or coarse table, but with no amalgamator.

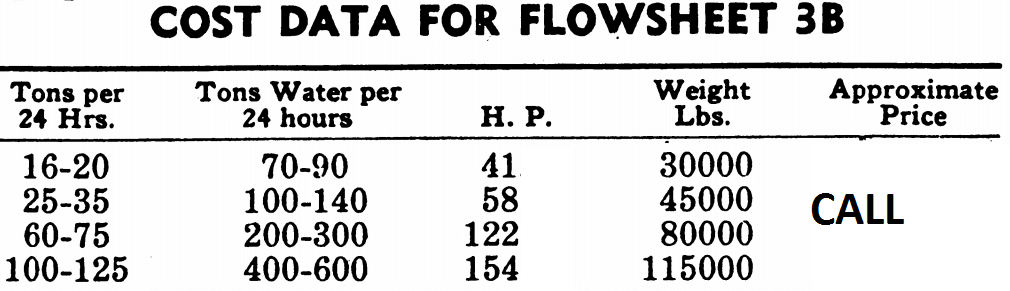

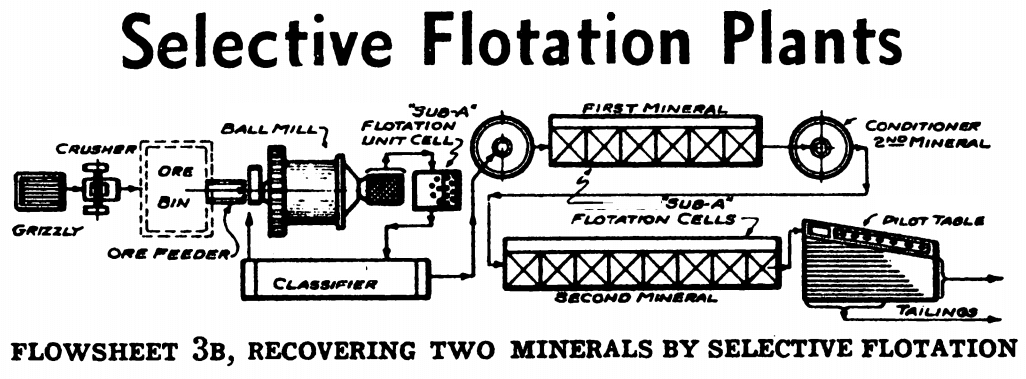

Below are prices and data for a selective flotation plant where two minerals are to be recovered as separate concentrates. This includes all necessary equipment as shown on Flowsheet 3B.

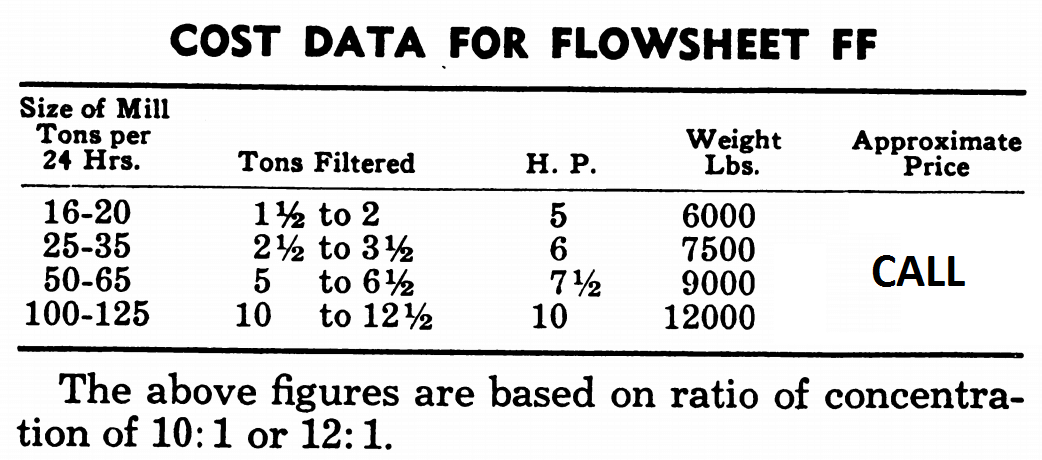

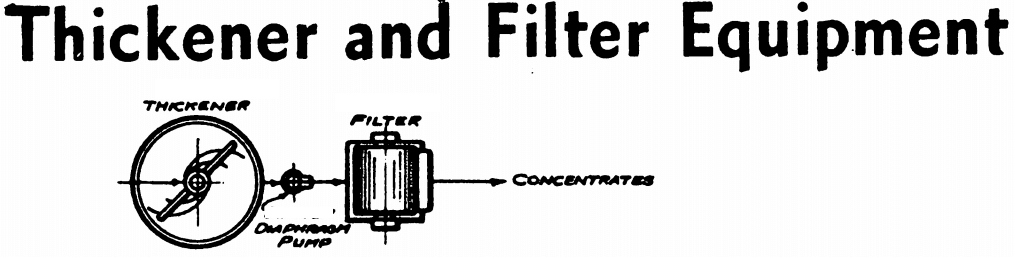

If thickener (including mechanism superstructure, and wood tank) diaphragm pump and filter are required in Flowsheet 1, 2B, or 2J, add the following prices to those already given. For selective Flotation Plants, Flowsheet 3B, add 75-80 % to the weights and prices shown below to cover’ the extra thickener, diaphragm pump, and filter for the second concentrate.