Table of Contents

I once had to conduct an MIBC frother test to confirm if it could give me better flotation results than the glycol frother my client was using. The technical/metallurgical problem we had in the plant was best described in the video below as well as a poor concentrate grade.

My “challenge” was that since MIBC is alcohol based, it is deemed explosive and requires a non-sparke pump.

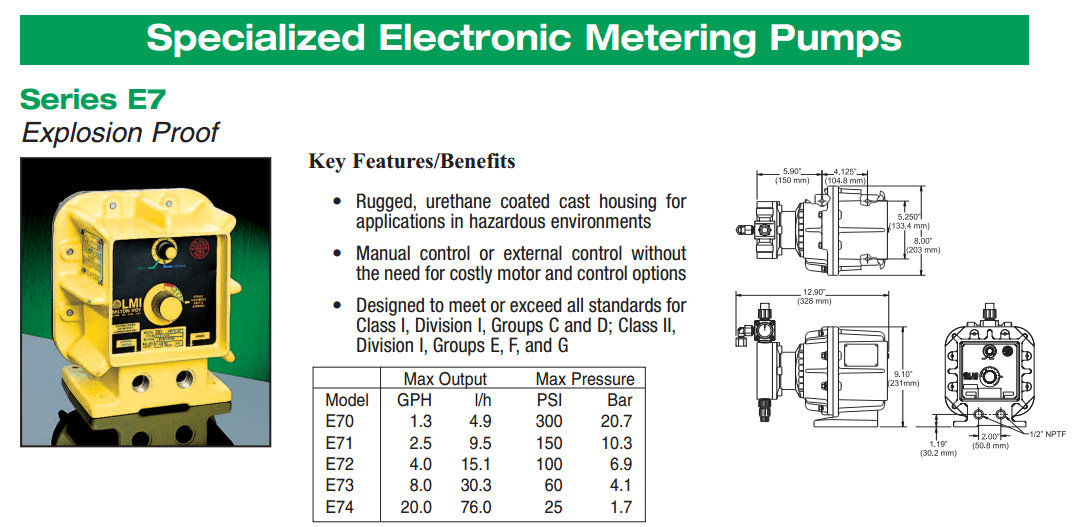

I really personally like the LMI Milton Roy E series.

Some frothers contains both an alcohol solvent and a glycol. The alcohols tend to cause problems with rubber over a period of time. So sometimes peristaltic pumps can have the tubing deteriorate. I often recommend LMI or FMI pumps to feed the material. Clarkson feeders will certainly work since all the components are generally stainless steel.

See, MIBC is superior to pine oil at achieving high grade concentrate. An MIBC formed froth recover less water and provide better drainage of mechanically-entrained particles. MIBC, however, lacks staying power, so often stage-addition is needed to maintain froth on the scavenger cells. Froth height can also be a problem with heavily-mineralized froths but the use of wash water addition as is done in Column Flotation can overcome this problem.

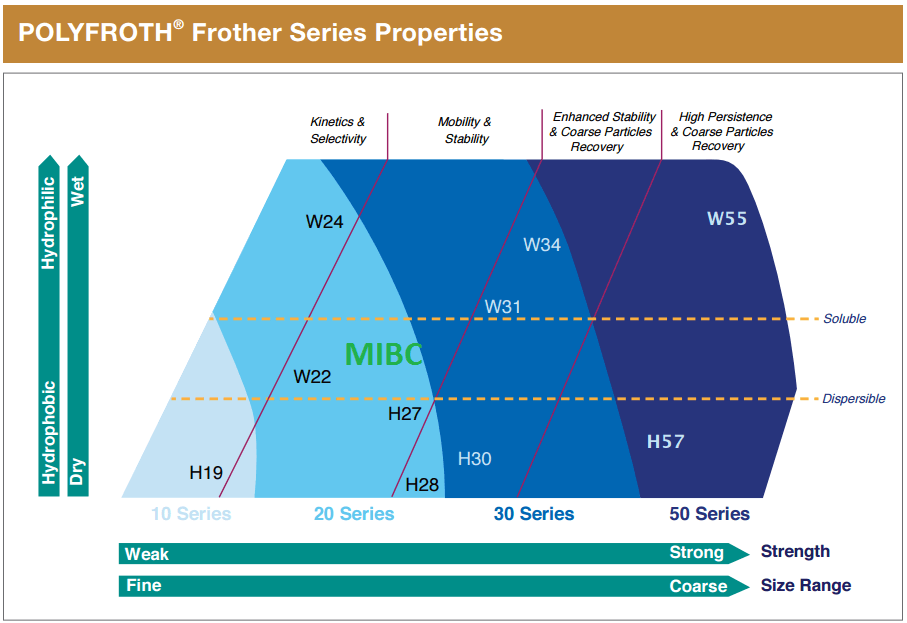

In the flotation of minerals, a frother or combination of frothers is chosen depending on the requirements of the mechanical and interfacial rheology characteristics of the froth. In addition to technical advantages, there are also economical advantages in using blends. Often in sulfide flotation, two or more frothers will be blended to improve flotation efficiency. Frequently, a short-chain alcohol such as MIBC is chosen as a versatile frother together with a higher-molecular-weight frother, such as pine oil or a PPG type, which leads to improvements of the froth or bubble size, especially when coarser particles must be floated.

MIBC did increase flotation concentrate grade

Compare Frother Strengths

Explosive-Proof no-sparke Pump

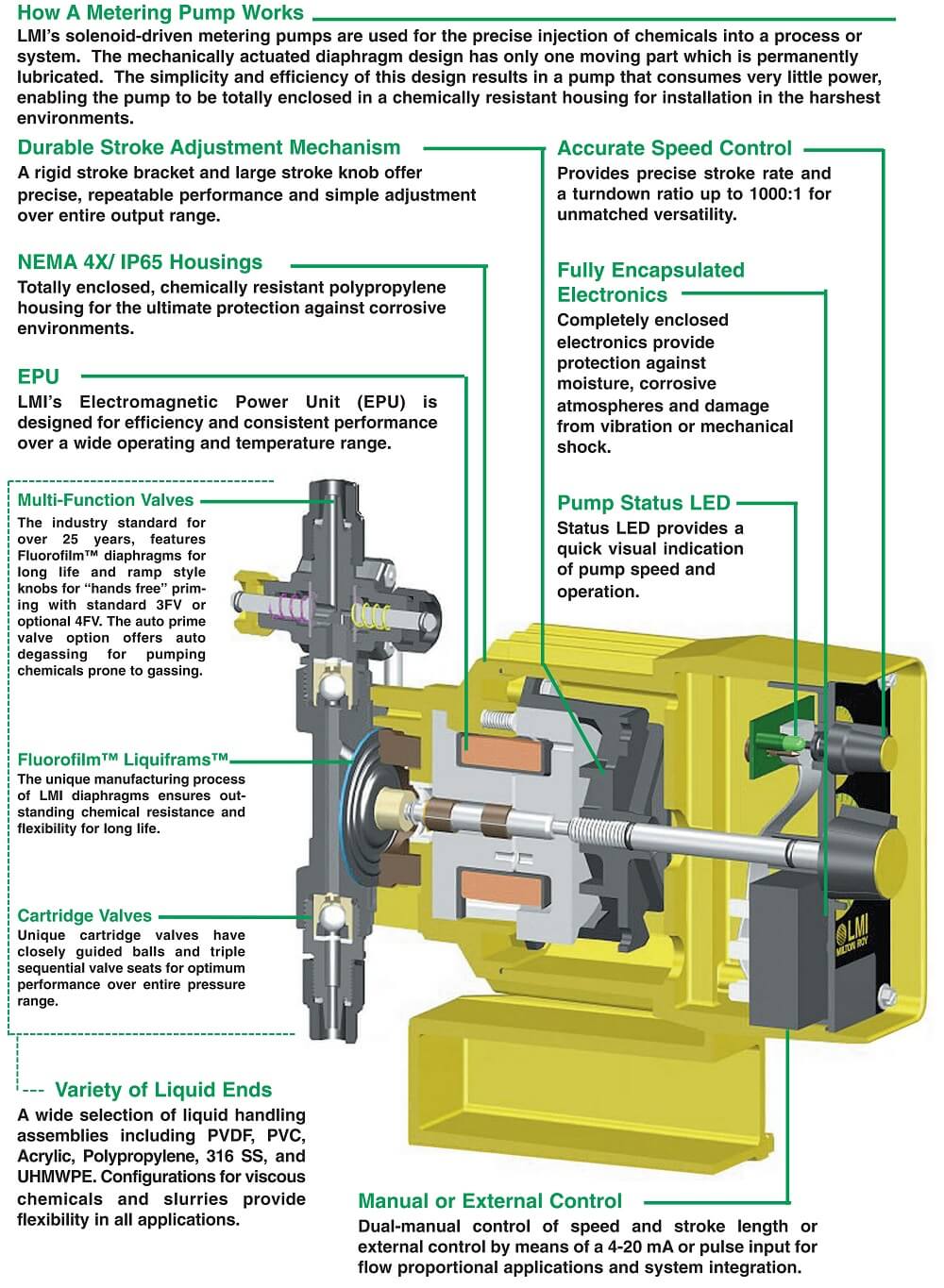

LMI’s solenoid-driven metering pumps are used for the precise injection of chemicals into a process or system. The mechanically actuated diaphragm design has only one moving part which is permanently lubricated. The simplicity and efficiency of this design results in a pump that consumes very little power, enabling the pump to be totally enclosed in a chemically resistant housing for installation in the harshest environments.

Durable Stroke Adjustment Mechanism

A rigid stroke bracket and large stroke knob offer precise, repeatable performance and simple adjustment over entire output range.

Accurate Speed Control — Provides precise stroke rate and a turndown ratio up to 1000:1 for unmatched versatility.

NEMA 4X/ IP65 Housings

Totally enclosed, chemically resistant polypropylene housing for the ultimate protection against corrosive environments.

EPU

LMI’s Electromagnetic Power Unit (EPU) is designed for efficiency and consistent performance over a wide operating and temperature range.

Fully Encapsulated Electronics

Completely enclosed electronics provide protection against moisture, corrosive atmospheres and damage from vibration or mechanical shock.

Pump Status LED

Status LED provides a quick visual indication of pump speed and operation.

Fluorofilm™ Liquiframs™

The unique manufacturing process of LMI diaphragms ensures outstanding chemical resistance and flexibility for long life.

Cartridge Valves

Unique cartridge valves have closely guided balls and triple sequential valve seats for optimum performance over entire pressure range.

Multi-Function Valves

The industry standard for over 25 years, features Fluorofilm™ diaphragms for long life and ramp style knobs for “hands free” priming with standard 3FV or optional 4FV. The auto prime valve option offers auto degassing for pumping chemicals prone to gassing.

Variety of Liquid Ends

A wide selection of liquid handling assemblies including PVDF, PVC, Acrylic, Polypropylene, 316 SS, and UHMWPE. Configurations for viscous chemicals and slurries provide flexibility in all applications.

Manual or External Control

Dual-manual control of speed and stroke length or external control by means of a 4-20 mA or pulse input for flow proportional applications and system integration.