Laboratory Conditioners and Super-Agitators are available in sizes to meet the need for a single batch unit, a multiple batch unit or a continuous pilot test plant size unit. This machine is designed for use in metallurgical, chemical and process laboratories to condition, agitate, aerate, or mix any combination of liquids or liquids and solids which will flow through a 10 mesh screen. It is distinctive in that it is particularly well suited to any job requiring highest conditioning efficiency or intense agitation and aeration and for handling pulps of high density and those containing high specific gravity solids the kinds of material so difficult to handle in ordinary units.

Laboratory Conditioners and Super-Agitators are available in sizes to meet the need for a single batch unit, a multiple batch unit or a continuous pilot test plant size unit. This machine is designed for use in metallurgical, chemical and process laboratories to condition, agitate, aerate, or mix any combination of liquids or liquids and solids which will flow through a 10 mesh screen. It is distinctive in that it is particularly well suited to any job requiring highest conditioning efficiency or intense agitation and aeration and for handling pulps of high density and those containing high specific gravity solids the kinds of material so difficult to handle in ordinary units.

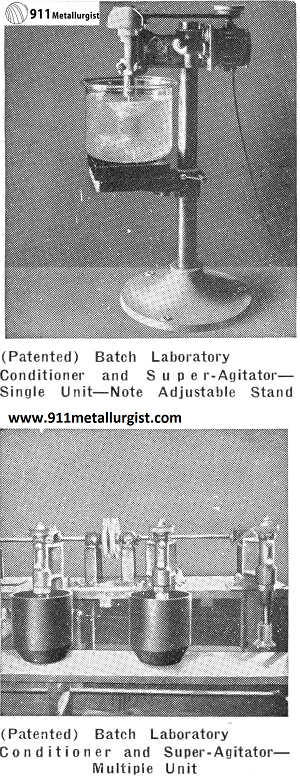

The (Patented) Batch Laboratory Conditioner and Super-Agitator is a simple flexible unit, low in cost and durably constructed for dependable operation. This unit approximates, as closely as possible in batch testwork, the operation of the commercial (Patented) Conditioner and Super-Agitator.

The patented central stand¬pipe provides positive and controlled circulation. Feed enters the standpipe and is positively circulated by the propeller thus, there is no settling of solids and no possibility of the material short circuiting across the conditioner with resulting insufficient mixing with reagents. Flow of pulp down the standpipe, combined with flotation of the propeller, will pull air into the propeller zone where it is finely disseminated throughout the pulp.

Three sizes of heavy, cast, spherical bottom Pyrex jars and two conditioning mechanisms with adjustable stands are furnished as standard laboratory equipment with the single unit.

These jars have a capacity of 1.75 Gals. (6.62 Liters), 3.37 Gals. (12.75 Liters), and 5.03 Gals. (19.03 Liters).

Multiple conditioner units, as illustrated, are available when it is necessary to condition several pulps simultaneously. A number of units can be mounted on a single base, with individual rubber covered supports and driven by V-belts from a common line shaft and motor.

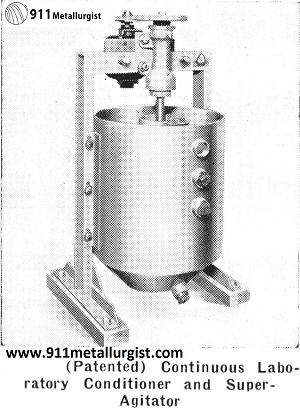

The (Patented) Continuous Laboratory Conditioner and Super-Agitator effects the conditioning of pulp in the continuous test

laboratory or pilot plant that helps to produce results that can be duplicated in actual plant practice. This unit is ideal for continuous test work, as each sample can be thoroughly conditioned before flotation, with intermediate discharge points allowing adjustment of conditioning time.

This machine is rugged, self-contained, and easily portable. Unit is equipped with an all-steel tank which can be completely drained through the plug in the conical base. The superstructure supports the shaft, with totally enclosed ball bearing housing, and motor drive.

This conditioner can also be used as a pulp storage tank, as a source of constant feed to a concentrating table or filter, or as an agitator.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.