Table of Contents

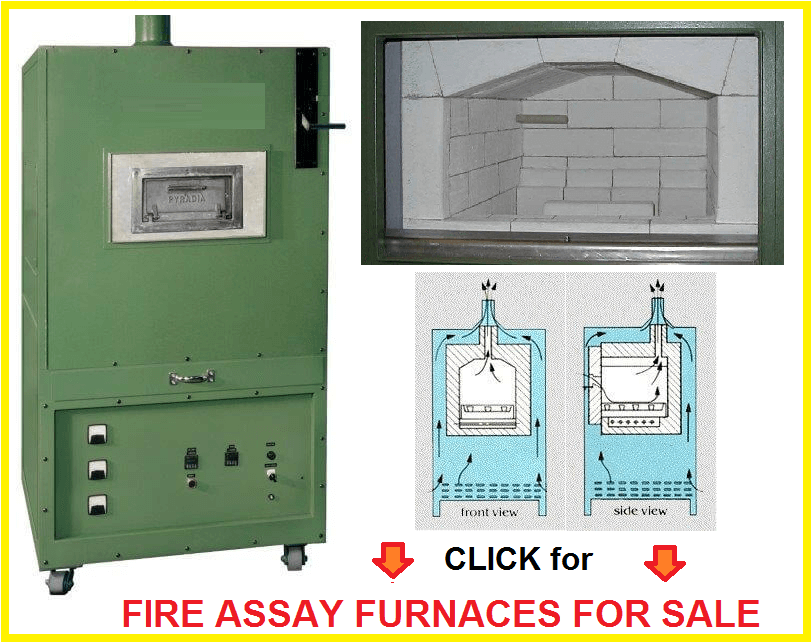

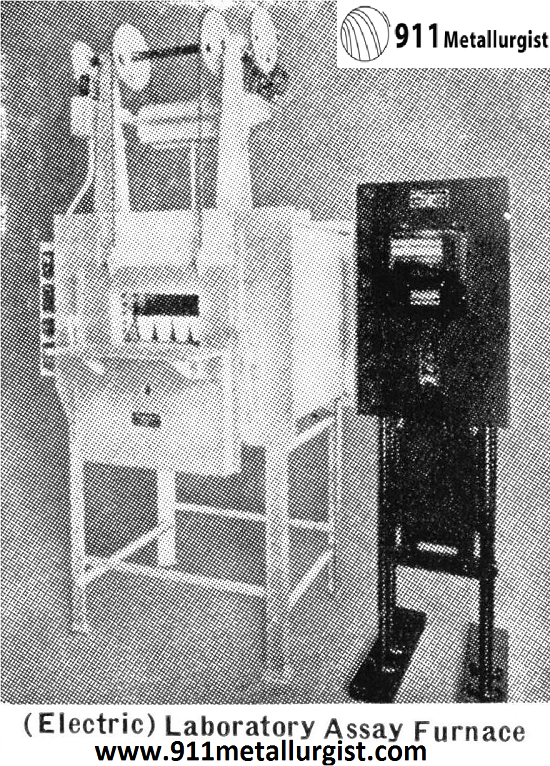

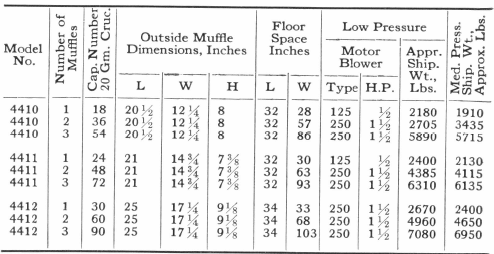

Electric Laboratory Assay Furnace

The (Electric) Laboratory Assay Furnace provides absolute, constant control of temperature, as well as positive control of atmospheric conditions. It is economical, clean, noiseless and no muffles are required. Off- peak power is frequently used, resulting in low operating cost.

Heating elements are U- shaped bars of nickel chromium, connected in series by nickel strips and iron clips for good contact. With the automatic control provided, there is no danger of overheating or burning out parts.

No muffle is required as the furnace is of the open type. Crucibles and cupels are supported on a crucible hearth of extremely high thermal conductivity. Low sides and back wall protect the bottom heating elements in case of spills.

Furnace lining is composed of specially designed refractory blocks, enclosed in a jacket of high-temperature insulating brick 4½” thick. This, in turn, is surrounded by a thick layer of low-temperature insulation and steel jacket.

Air is drawn into the furnace, and fumes carried from it, by means of an electric exhaust fan, or by natural draft operating through a manifold at the rear of the furnace.

(Electric) Laboratory Assay Furnace is available in four models; choice of manual or automatic control of temperature, manual or electric door operation, forced or natural draft in the ventilating system.

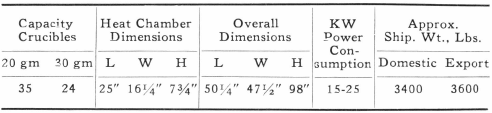

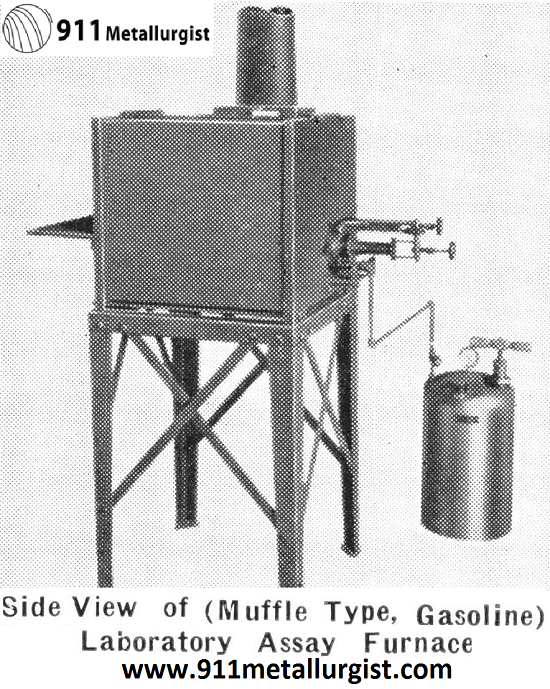

Muffle Laboratory Assay Furnace

The (Muffle Type, Gasoline) Laboratory Assay Furnace is ideal where a light, easily portable, and compact furnace is desired. Type 481 in this series is the lightest assay furnace with which dependable results are obtainable. Stand and clay-lined pipe have been omitted on this type to reduce weight to a minimum for prospecting. Each of the other units is furnished with stand, burner, tank, pipe and fitting, one clay-lined pipe and a muffle.

The Gasoline Burner which is supplied with this furnace is of the double injector type and gives the quickest and highest possible heat. The air pump on the gasoline tank is built inside the tank which makes a strong and compact unit. All tanks, except the small one supplied with Type 481, are equipped with pressure gauges.

Complete data and estimates on assay and test equipment will be gladly furnished. Let us make recommendations for your proposed installation.

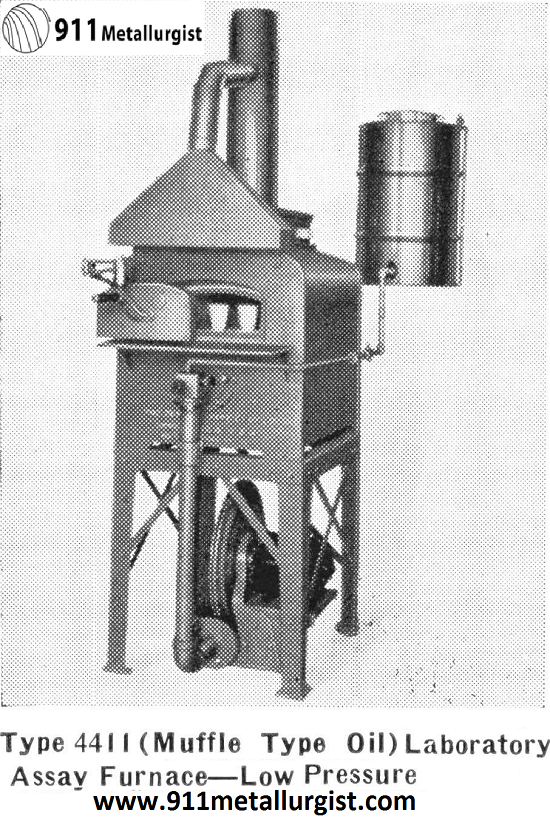

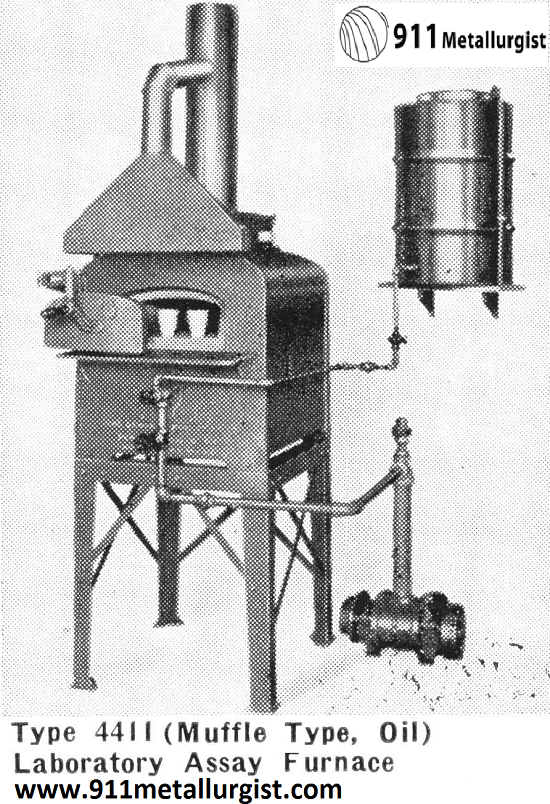

Muffle Laboratory Assay Furnace

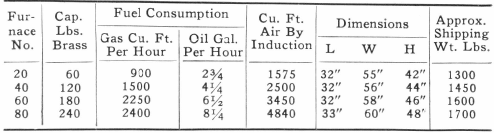

Where economy, efficiency, large capacity operation and quick results are required, oil has proved to be an ideal fuel for assay furnaces. With the (Muffle Type, Oil) Laboratory Assay Furnace a fusing heat is obtainable in 30 minutes and reducing or oxidizing atmospheres can be maintained absolutely. Three sizes of muffles have been standardized and these are built in one, two, and three muffle combinations for safe shipment and convenience in assembling. Any number of units up to twelve can be connected to one large blower and to one oil supply, thus reducing the unit cost of large batteries of furnaces. Each installation is equipped with its own motor blower, thus rendering it independent of any other equipment about the plant. The control of the burner is positive and variable and exact adjustments are possible.

Low Pressure (Muffle Type, Oil) Laboratory Assay Furnace is designed for installation wherever 50 or 60 cycle electric current is available for blower motor. Medium Pressure (Muffle Type, Oil) Laboratory Assay Furnace is designed to give assayers who are without 50 or 60 cycle current the advantages of a fuel oil furnace. One of the most efficient combinations is the positive pressure belt driven blower that can be connected to any lineshaft or gasoline engine. As many assayers prefer medium pressure burners, the belt driven blower can be replaced with a blower of the same type and capacity, but with a standard speed motor equipped with V-belt drive.

Laboratory Melting Furnace

The (Fisher-Monarch) Laboratory Melting Furnace is an ideal unit for melting small quantities of brass, copper, aluminum, gold, silver and other metals and alloys. This unit is of the stationary crucible type and requires only a very small floor space. The melting chamber is of heavy, durable construction and is furnished with a reverse or swing cover actuated by a lever arm operated from the rear of the furnace. Sufficient leverage is provided to easily lift cover. Fuel used for melting may be gas, crude oil, fuel oil, or any liquid hydro-carbon sufficiently fluid to pass through the burner. The time required for an average heat ranges from twenty to forty minutes for capacities up to 825 pounds. Every feature of this furnace has been carefully engineered.

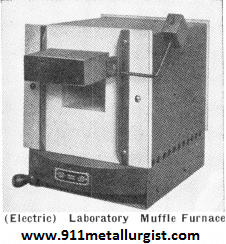

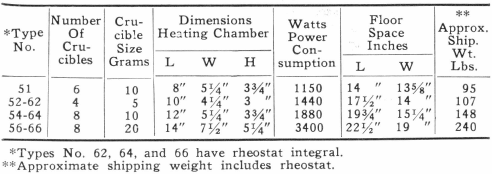

Laboratory Electric Muffle Furnace

General laboratory work such as fusions, ignitions, heating metals and alloys is efficiently done in this furnace. It is also useful in a testing laboratory for roasting concentrates and mill products prior to cyanidation or other treatment.

This furnace is of the muffle type. There are four heating units in the furnace, each consisting of a heating coil sup¬ported in grooves of a refractory plate. The top and bottom units are interchangeable, likewise the two side units. Safe working temperature is 1750°F, but for intermittent periods of short duration the furnace may be operated at a maximum temperature of 1850°F, By means of a selective connection at the rear of the furnace either 115 or 230 volts A.C. or D.C. may be used.

Control of temperature at any point between 1000″ F and the maximum of 1850° F may be supplied by a separate rheostat or by one built integral with the furnace. This unit can also be furnished with a special indicating pyrometer to provide an easy means of reading heating chamber temperature if desired.

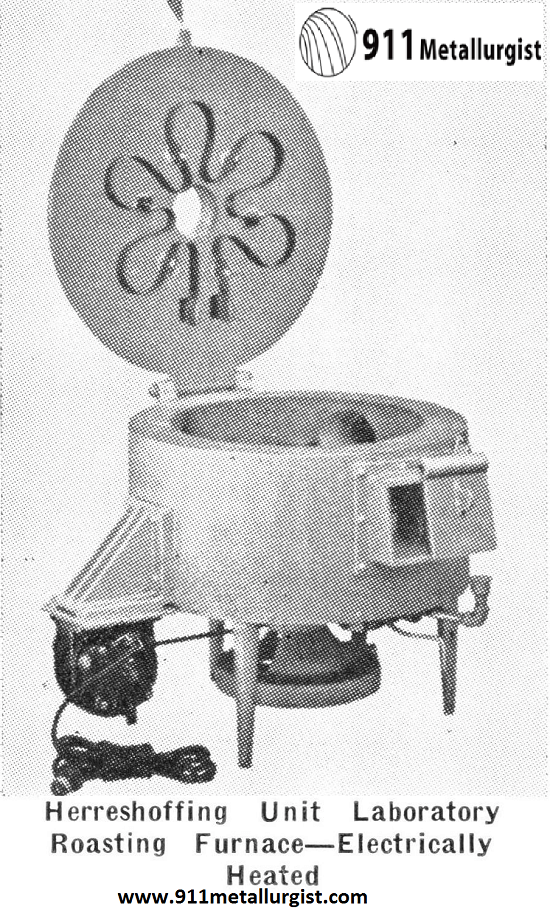

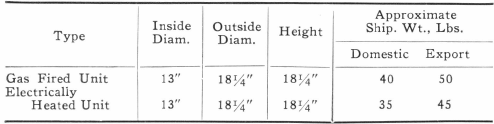

Laboratory Roasting Furnace

In order to meet the demand for a very small roasting furnace for the purpose of conducting laboratory tests, there has been developed the Herreshoffing Unit Laboratory Roasting Furnace. It is a self-contained apparatus including all of the necessary factors for making small volume tests.

This unit has proved itself a valuable device and excellent results have been obtained in the roasting of ores, the revivification of oil filtering media, the calcination of lime¬stone and the heat treatment and drying of other materials.

Standard equipment provided with this unit includes a 1/20 H.P., 110 volt, 60-cycle motor driving blower, gas burner and a 3″ diameter by 24″ long stack with damper. However, the Herreshoffing Unit Laboratory Roasting Furnace is so designed that an electrical heating element can be attached at any time.

This unit is compact, light and efficient and is an extremely useful item for any ore dressing laboratory. Detailed information will be promptly furnished on request.

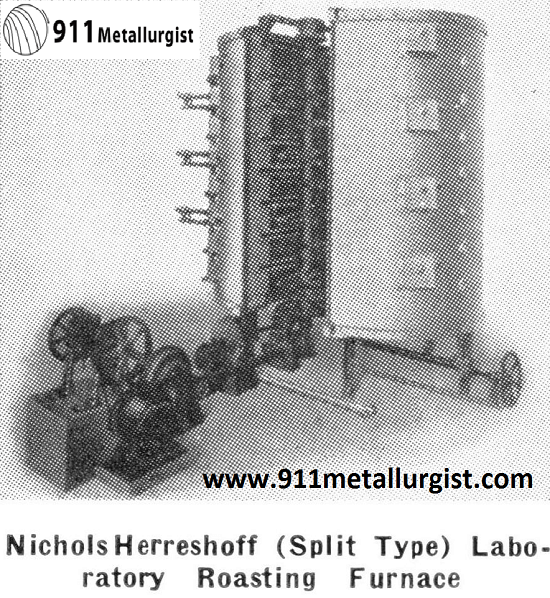

Laboratory Split Roasting Furnace

The Nichols Herreshoff (Split Type) Laboratory Roasting Furnace is designed particularly for experimental and test work in chemical and metallurgical laboratories. It is ideal for making test runs of various materials and ores where¬by the conditions can be regulated to approach actual practice with larger units.

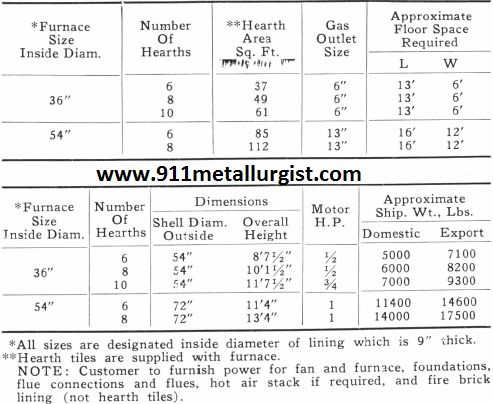

Many of these furnaces are installed throughout the United States and the popular sizes (36″ inside diameter with six or eight hearths and top dry hearth) are normally carried in stock.

The Nichols Herreshoff (Split Type) Laboratory Roasting Furnace is separated vertically through shell and brickwork. One-half is stationary and mounted upon cast iron columns; the other half is mounted upon rollers and rails so that it can be readily separated from the stationary half to allow ample room for cleaning, inspection and repairs.

Shaft and arms are air cooled by fan pressure in accordance with Nichols Herreshoff cooling system. Rabble teeth are removable from arm and speed of rabbling may be changed to suit conditions.

Thermal conditions in such a small furnace may call for the use of some form of extraneous fuel which would not be necessary in larger units and means are provided for attaching either gas or oil burners. Openings are also provided for installation of pyrometers on all hearths.

Power source, foundations, sidewall brick lining and stack or flue connections are not furnished, but in general, the furnace is shipped ready to set up, line and operate. Foundation blueprints are supplied with each furnace.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.