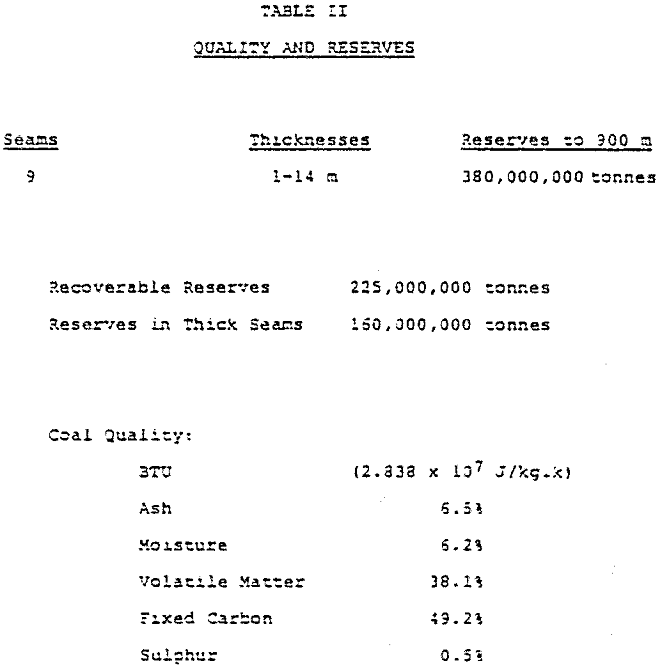

In evaluating the quality of coal, Storm King Mines carried out two years of exploration drilling. This drilling has established in-place reserves in excess of 500 million tonnes in seams greater than 1 meter thick, having an energy content in excess of 2.84 x 10 7 J/kg.k.

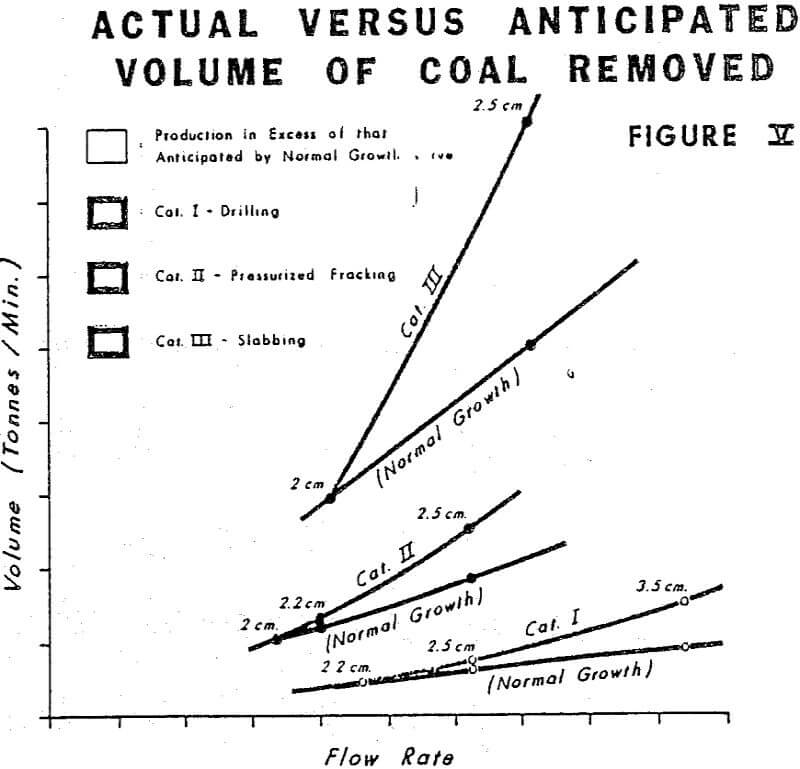

During the Fall of 1981, SKM conducted its first hydraulic mining tests. Utilizing equipment from the oil field industry and slighlty modifying a roadheader, tests were conducted both on exposed outcrop and underground. They are nozzle size, flow rates, pressure, and energy requirements. The idea was to fix rates of production, manpower, support requirements, water requirements, pump sizes and the resultant energy consumption, and other mine operating parameters.

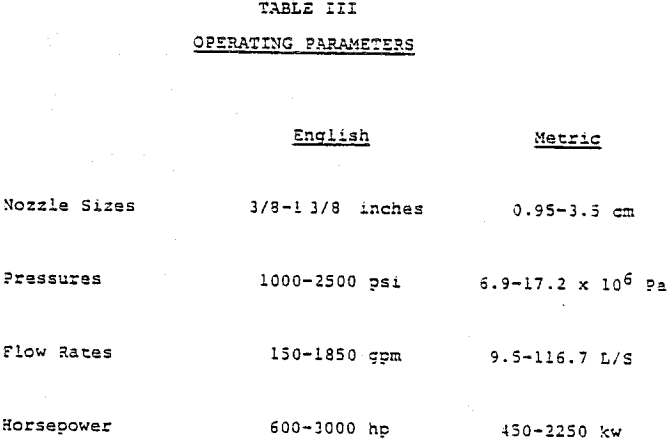

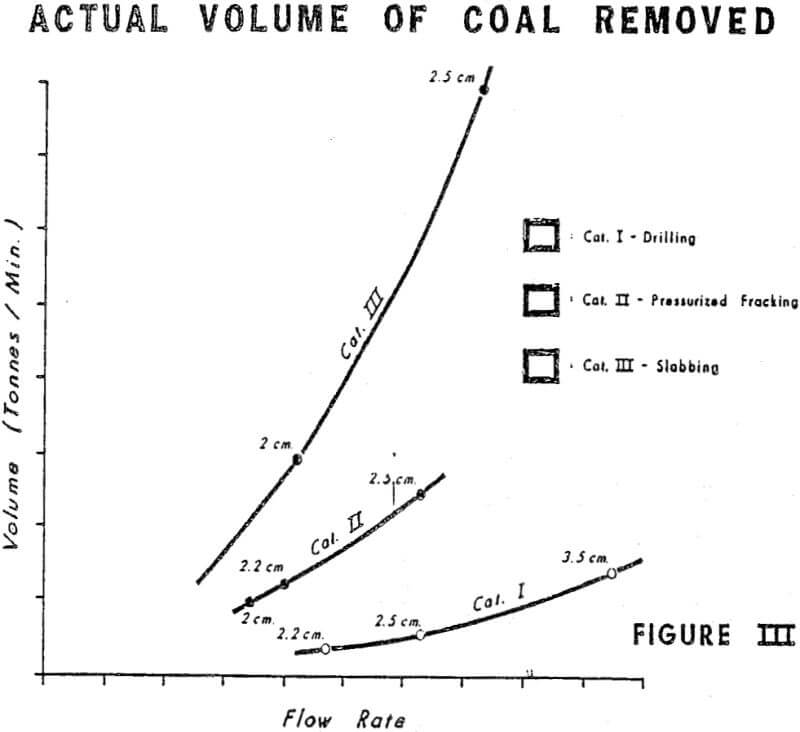

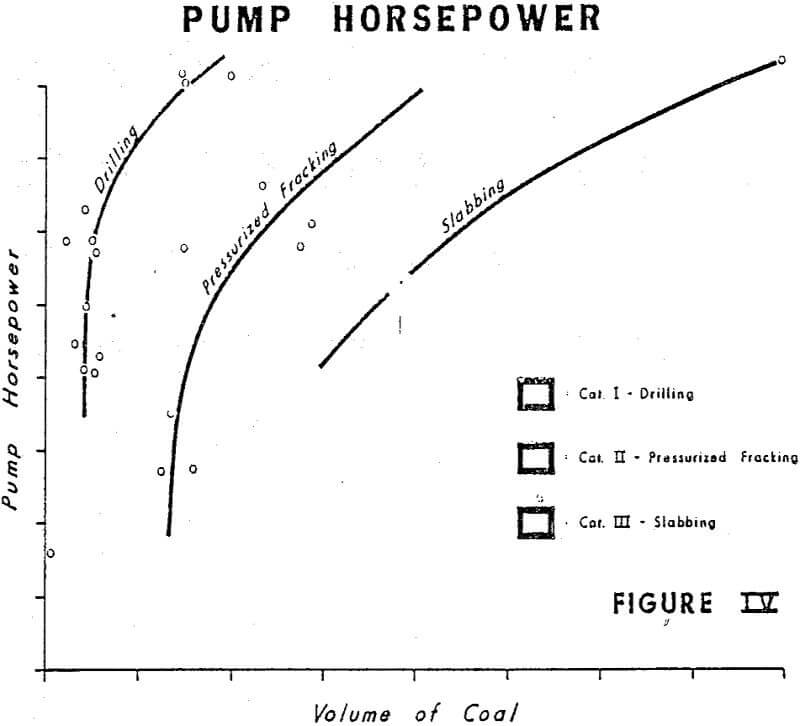

Both the graphs of flow rate and pump horsepower to volume of coal removed display the desired patterns. These are actually the graphs which isolated the categories previously discussed. What they indicate is a transition series from purely drilling to purely slabbing to a free face. None of the tests represent either extreme, but, as stated by the categorical analysis earlier, various combinations.

The evidence points to the fact that increasing the size of the nozzles can benefit the production rate. The limits to the size increase are both natural and economically induced. The economic factors deal primarily with material handling including rate of production, size of plant, water storage capacity, etc.

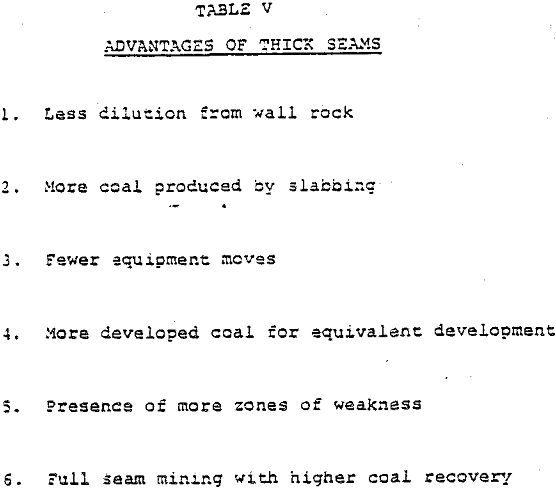

In determining the rate of production, several factors are to be considered. During the tests we operated in a 2.6 meter seam. When full scale operations commence, we will be operating in two parallel 6.6 meter seams. During the tests, the excavation was not large enough that the effect of overburden pressures assisted in breaking the coal. During the test we operated principally in the pressurized fracturing category driving development headings. In full scale operations, development headings will be driven by roadheaders and hydraulic mining will be utilized solely in production stopes whose dimensions (13.1 m x 6.6 m x 27 m) will allow for wall rock pressures, gravity and slabbing to open faces to keep production rates high.

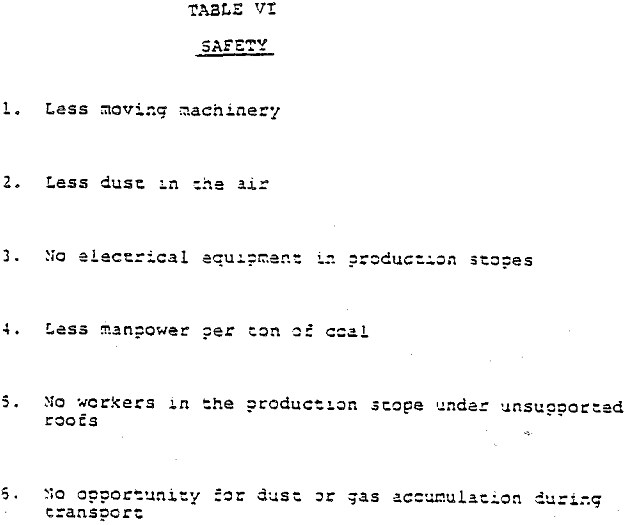

All operations were carried out in compliance with MSHA standards. It is noteworthy, that hydraulic mining has a superior safety record. Table VI enumerates several of the areas where safer conditions exist.