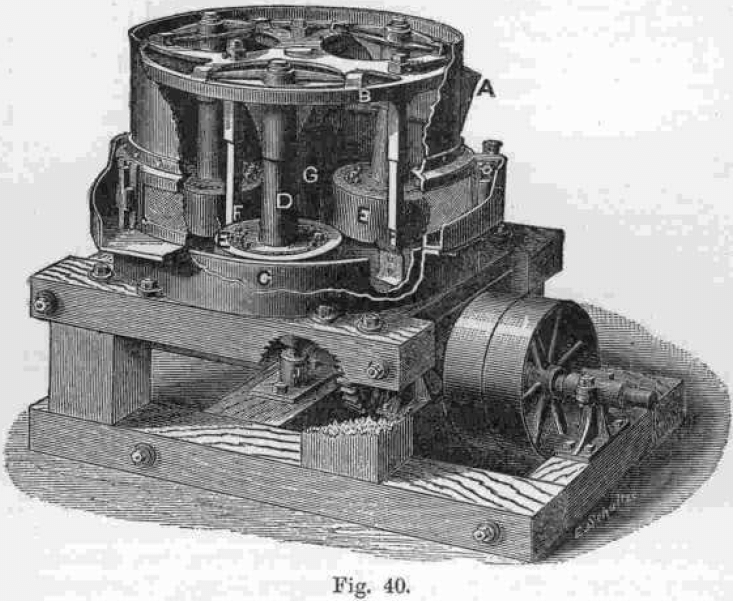

The Huntington Roller Mill, here described as a type of the many good roller mills now in use, is best suited for the fine crushing of ores which are not too hard. It consists of an iron pan, at the top of which a ring, B (Fig. 40), is set, and attached to this are three stems, D, each of which has a steel shoe, E, fastened to it. The stems are suspended from the ring and are free to swing in a radial direction, as well as to rotate round their own axes, whilst the whole ring, B, with the stems and shoes, revolves round the central shaft, G. The shoes or rollers, as they are called, are thus driven outwards by centrifugal force and press against the replaceable ring die, C. In front of each roller is a scraper, F, which keeps the ore from packing. The rollers are susp ended with their bases at the distance of 1 inch from the bottom of the pan, which can also be replaced when worn. The lowest part of the screen is situated

ended with their bases at the distance of 1 inch from the bottom of the pan, which can also be replaced when worn. The lowest part of the screen is situated

a little above the top of the rollers, and outside it there is a deep gutter into which the ore is discharged, and from which a passage leads to the amalgamated plates. The ore and water being fed into the mill through the hopper, A, generally by an automatic feeder, the rotating rollers and the scrapers throw the ore against the sides where it is crushed to any required degree of fineness by the centrifugal force of the rollers acting against the ring die. From 17 to 25 lbs. of mercury are placed in the bottom of the pan, the clearance below the rollers permitting them to pass freely over the mercury without coming in contact with it, so that it is not stirred up and “ floured,” but the motion is such as to bring the pulp in contact with the quicksilver. The speed of the mill is from 45 to 75 revolutions per minute. The ore should be broken in rock-breakers to a maximum size equal to that of a walnut, or, better still, of a cobnut, before being fed in. The action of the rollers is one of impact rather than of grinding, the ore being granulated without the production of much slimes. The free gold, as soon as it is liberated from its matrix, is in great part amalgamated and retained by the mercury at the bottom of the pan, the remainder being caught on the plates outside the mill. Coarse gold is caught inside and fine gold outside the mill, but the yield inside is comparatively small when ores with high percentages of sulphides are in course of treatment.

The mill is particularly adapted for the treatment of ores containing brittle sulphides, which, if pulverised by stamps, are liable to become “slimed,” and so to be in an unsuitable condition for concentration. It is also suitable for argillaceous quartzes, which yield their gold more readily under the “ puddling” action of the rollers than when pounded by stamps. Moreover, the Huntington mill does much more satisfactory work than stamps on soft ores or in regrinding coarse tailings. The reason for this lies, of course, in the relatively large amount of screen area in the mill and its consequent high efficiency of discharge, a point in which stamps are decidedly inferior to it. As the splash is heavy against the sides the wear of the screens is somewhat rapid, but they can be very quickly replaced.

The capacity of a 5-foot mill, the one which is most commonly in use, is from 10 to 20 tons of rock per day through a 30-mesh screen, the power required being from 10 to 12 H.P. The weight of each of the roller shells, which are replaceable, is about 170 lbs. The wear and tear on the replaceable parts is very great, amounting to about 14 ozs. per ton of rock crushed when soft ores, previously broken small, are being treated. If large pieces of hard quartz are fed into the mill, or if the mill is overfed, the mercury is splashed against the screens and passes through with the pulp, and when by accident pieces of iron or steel are introduced, the ring die is occasionally broken.

Another source of disaster in Huntington mills lies in the use of acidulated water, such as that derived from mines or encountered when decomposing pyritic ores are treated; the mill is rapidly corroded and rendered unfit for work by such water.

The chief advantages supposed to be gained by the use of Huntington mills instead of stamps may be thus epitomised:

- Reduced First Cost,—The cost for the same capacity is not more than two-thirds that of stamps, even at the manufacturer’s’ shops, while the difference in favour of the mill is even more in outlying districts from its light weight, and corresponding low freight, and from the cheapness of its erection.

- Saving of Power.— The mill is said to run with about one- half the power per ton of ore crushed.

- The wear and cost of renewals is less for the mill than for stamps, the cost being from twopence to threepence per ton of ore for the former, against about five-pence or six-pence for the latter.

- There is less loss by flouring of amalgam and quicksilver, while the good discharge and absence of grinding leaves the pulp in a better condition for concentration.

The first three advantages appear to refer only to such soft and brittle ores as are especially suited to the Huntington mill. The mill requires to be set to work in an intelligent manner by experienced and skilful hands, and watched carefully. The dangers of over-feeding have been already alluded to. One difficulty in automatic feeding is that self-feeding, such as is carried on by stamps, is impossible. The automatic feeder must work separately and be set to feed a certain weight of ore per hour, this weight having been determined by trial. If, after this, there is any change in the hardness of the rock, no automatic change in the rate of feeding takes place, and the machine may be choked up or run at below its maximum capacity unless watched and the feeder regulated. Another difficulty is in the quantity of water to be added. An excess of water, making thin pulp, does not favour internal amalgamation, and it may be stated that, in general, the pulp should be kept as thick as possible, consistent with its prompt discharge through the screens when sufficiently fine. If the pulp is too thick to run easily over the copper plates outside the mill, water may be added there by means of a perforated pipe. The rate of running should be as high as possible, since, if the other conditions are the same, the crushing power varies as the cube of the number of revolutions per minute. The usual rate is from 70 to 100 revolutions per minute.

A few examples are appended of the results obtained in actual practice by this excellent machine. At the Spanish Mine, Nevada County, California, there are four Huntington mills, three of 5 feet diameter and one of 4 feet diameter. The ore is free-milling and is passed through a Blake stone-breaker and thence to the mills. The four mills run at 58 revolutions per minute, and pulverise 35 tons of ore each in twenty-four hours, to pass through a slot screen equal to 20 mesh. The pulp is passed over the usual amalgamated plates after leaving the mills, and ¼ oz. of mercury is added with each ton of ore. Forty-five per cent, of the gold recovered comes from the inside of the mill, where the amalgam obtained is much richer than that from the plates. The loss of quicksilver is from 1/15 to 1/30 oz. per ton of ore, and the total cost of milling is about one shilling per ton, while for the month of November, 1887, it was only tenpence per ton. The ore is a soft talcose slate, containing streaks and veins of ferruginous quartz, carrying gold. The chief trouble in working lies in the frequent re-adjustment of feed which is found necessary. In a special test run of one month 42.4 per cent, of the gold contents was extracted, and the remainder lost in the tailings. This poor result was probably due to over-feeding, but profits were made, nevertheless, although the ore yielded only a little over 1 dwt. of gold per ton in 1887 and 1888. Twenty-two horse-power were used by the Huntington mills in crushing from 120 to 140 tons per day.

At the Shaw Mine, El Dorado County, a 5-foot mill, making 50 revolutions per minute, pulverised 10 to 12 tons per day, so as to pass through a 25- to 30-mesh screen. At the Mathines- Creek Mine, in the same county, a 5-foot mill pulverised 9 to 10 tons per twenty-four hours, so as to pass a screen equal to a 40 mesh. At the Monto Cristo Mine, Mono County, two 5-foot mills, running at from 65 to 75 revolutions per minute, pulverised 2 tons of ore per hour to pass a screen equal to a 40 mesh ; 25 lbs. of quicksilver were charged into each mill at the commencement of the run, and about ½ oz. more added each half hour.

Although cases have been adduced in which 90 per cent, of the gold contents of an ore crushed in the Huntington mill was retained inside the machine, this is decidedly exceptional, and the mill is probably inferior to the stamp mill as an amalgamator on many ores, although its product is better adapted for treatment on copper plates and by concentration.