Table of Contents

Running a thickener properly isn’t as easy as it looks. True enough, a thickener doesn’t make a racket like a ball mill, or spew out froth like a flotation machine, or bounce up and down like a jig, but down inside that big tank there is a lot going on just the same.

You, as operator of a thickener, or group of thickeners, will find out, if you haven’t already, that your machine is as slow and deliberate in operation as a sleepy elephant, and just about as hard to control if you let it get out of hand. We want to suggest some ways by which you can keep your thickener headed in the right direction. To be able to do that is a good idea for two reasons: first, because your job as thickener operator is just as important to the success of the company as any other job in the mill; second, your job is more fun and is easier when you do it well. If you study thickener operation a little and think about it, you can make a really interesting job out of it.

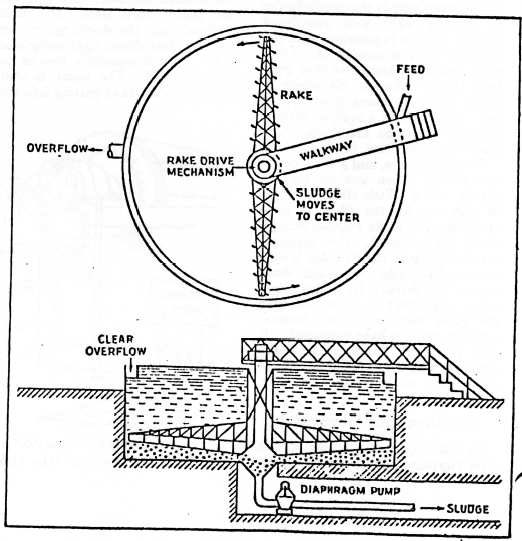

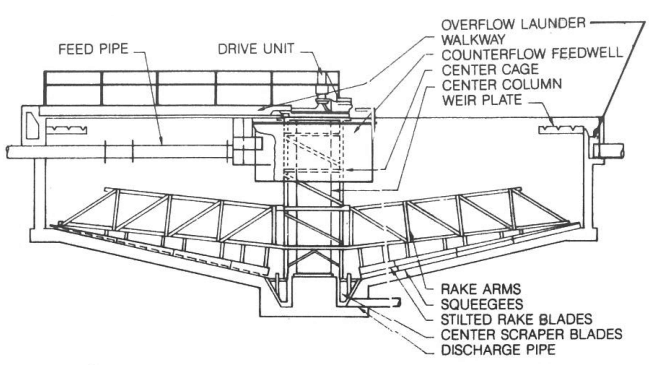

To start at the beginning, let’s see what a thickener is. We have fixed up a couple of diagrams on this page to show you the inside of one,and, as you see, the main elements are the tank, the rake arms, and the drive mechanism. In operation, the tank is full of whatever it is you are thickening, usually a pulp of ground ore, or tailing, and water. The liquid overflows around the edge of the tank, and the solids, also called the slime or the sludge, settle to the bottom of the tank. The rake arms go around very slowly, and the plows set on the arms gradually work the sludge over to the center of the tank bottom, along with lime sacks, old shoes, your lunch box, or anything else you drop into the tank that won’t float.

The main idea in running a thickener is to get the sludge that comes out of the bottom of the tank as thick as you can, and, at the same time, keep the overflow clear. Also it is important just to keep her going, and there are times when that may not be so easy.

The purpose of a thickener is to thicken, which is simple enough, but it isn’t enough for you just to know that. You also ought to know why and how this thickening is to be done. We can’t tell you the whole story here, but we can give you a start on it, and then we’ll ask you to finish the story for you.

The simplest use of a thickener in a metal-mining operation is to get water out of a pulp; for example, in a desert country where water is too valuable to be thrown away with the tailings. There you have a thickener treating the tailings and recovering some of the water to be sent back to the mill and used over again. The partially dewatered tailings are then easily stacked up. Other similar uses are to recover water from concentrates, or to cut down on the water content of a flotation feed.

Thickening In Cyanidation

Another use of thickeners is in the operation known as counter-current decantation, or C.C.D., for short. Here you have a string of thickeners that are not just recovering water, but are acting as big washing machines. In a cyanide plant, after the pulp has been treated in the agitators, the gold has dissolved in the solution and the problem is to get the solution separated from the solids, because if you lose any solution with the solids when they go out as tailing, you lose gold, too, and that isn’t good business.

So you start the mixed solids and solution in at one end of a line of thickeners, and start clear weak solution in at the other end. The solids go from the bottom of one thickener to the top of the next; the solution overflows from one thickener to the next, but in the opposite direction to the way the pulp is travelling. As the solids go up the line, more and more gold-bearing solution is washed out of them by the solution which is headed down the other way. The result is that the solids that come out of the bottom of the last thickener have so little gold in them that they can be thrown away; and the solution that overflows the first thickener now has recovered a lot of gold.

If that sounds a little complicated right now, don’t worry about it, but if you are in a C.C.D. plant treating gold ore, or perhaps aluminium, manganese, or nickel ore, it will pay you to study out what is going on and why. But no matter whether you are doing C.C.D. or straight thickening, remember that the main idea is still to get the sludge as thick as you can, and to keep the overflow clear.

Slime Layers

Since slime layers have not been much studied, the remedies proposed in the following are conjectural and not part of established industrial tradition or know-how. Where segregated slime layers form, they almost surely govern and limit thickener capacity, so something should be done about them. Since they almost surely arise from segregation of fines in the feed layer, anything that can be done to decrease the segregation should help. Deep feedwells should help, and indeed substantial capacity increases have been claimed in South Africa when deep-slotted feedwells were installed. Remixing, either internally or externally, of material from the slime layer back into the feed should help. It might be conjectured that deep-slotted feedwells were helpful precisely because they cause such recirculation to occur internally. Further, since the slimes are teetered on the total overflow emerging from the feed layer, they must settle against the entire overflow rate. Perhaps if materials were constantly withdraw n from the slime layer and were fed to a small auxiliary thickener, the solids throughput per unit of combined thickener areas would be increased.

It will help you understand what is going on in a thickener if you get a milk bottle and fill it with the thick- how the slime all settles together, leaving clear liquid behind; and how the slime line comes down rapidly at first, and then slows down and finally stops altogether. Look closely at the sludge after it seems to have stopped settling, and you will see little channels twisting up through the slime. Every so often a little squirt of water will run up one of these channels, and the slime will settle a little farther. You see, liquid has to be squeezed out to make room for the slime to pack down more tightly, and this liquid pushes out along those channels. The rakes travelling around help squeeze out liquid in just that way in the thickener.

Notice the difference between the way the slimes look when you stir up the bottle, and the way they look when they are all settled and packed down in it. The first way, the slimes are settling down, and the slime line comes down in the bottle pretty rapidly; the second way, the slimes are packed up like so much mud and the slime line stays put. Here’s how you can use that bit of information:

Suppose you come around to the thickener and find a lot of slime coming off in the overflow. That means you are either feeding more pulp than the thickener can handle, or not pumping sludge out of the bottom fast enough. But how can you tell which? One quick way is to take a sample of the pump discharge. If the sludge is thicker than the boss has told you to hold it at, you should pump faster and pull it down. But if the slime level does not drop down, then the tonnage must be cut and quick. Going still further, you may find that even with a dilute pump discharge slimes continue to overflow, and this means that you have run into a bad- settling ore. All that you can do tonnage increases the settling area per ton to be handled.

You can explore the inside of a thickener some evening when you haven’t much else to do and learn a lot about what goes on. To do this, fix up a sampler which is nothing but a milk bottle tied to a long stick marked in inches and feet. There has to be a cork in the bottle, and a string tied to the cork. Put the bottle down into the thickener as deep as you want it, then pull out the cork with the string. Wait a second for the bottle to fill, then pull it up, and there’s your sample. Then measure the distance on the stick, and this will show you how deep down the sample was taken in the thickener. In this way you can explore all parts of the thickener.

In general, the best indicator to tell you how the thickener is doing is the condition of the sludge being pumped out of the tank bottom. You will undoubtedly be required to take regular samples of the sludge, and probably record the weight of the samples you take, but it doesn’t do any harm to take a few more samples just to see how things are going. A great many skilful operators -take samples in a pint milk bottle (Doesn’t anybody drink anything but milk around here?), and they can tell by looking at the sample whether or not the thickener is “on the beam.” You can’t be expected to do that right away, but you may be able to in time. Of course, if you are made to take samples in a special container and weigh them on a special pulp balance, you probably won’t develop an “eye” for it, because you won’t have to. It won’t do any harm to try, though.

Thickener Segregation

With segregating pulps, flushing out the underflow line becomes more of a problem. The fines wash away, leaving heavy sands in the line, and they are hard to move. For this reason it is often unwise to try to push the plug with wash water to the underflow line’s destination. Drains that can be opened to discharge the plugging material should be provided at judicious points.

Segregating pulps also may give start-up problems that, in extreme cases, can be severe. The coarse segregates away from the fines and drops to the bottom at small diameters. There the rakes move slowly, and so do not have the sand-raking capacity to move all the segregated sands on into the discharge. Sand raked in soon forms a reef at small diameters that buries the rakes. Torque runs away. If the rakes are not shut down by a high torque cutout, enough force may be developed to crumple the innermost blades or otherwise damage the rake arms. Torque arms are of little benefit for this problem. Since they are hinged to the drive cage, they do not raise much at their inner ends where the problem develops. Rake-lift mechanisms are better, permitting a longer lime for a steady-state to be approached, in which settling fines raked in from large diameters are incorporated back into the segregating sands settlings at smaller diameters. These start-up problems are aggrevated in countercurrent decantation processes since the initial wave of segregated sand moves ahead of fines down the system. There are initially few fines even in the feed to downstream stages.

It is easier to say what not to do during start-up than what to do with segregation pulps. One of the worst things is to fill the thickener with water before starting solids feed. The feed stream becomes partially diluted while plunging to the bottom, and segregation is increased. The large volume of liquid holds back segregated fines longer, so it takes longer to attain a steady operating state. Ideally; feed should be introduced near the bottom of the empty thickener through a temporary’ distribution system. It usually suffices to run it in through the regular feed lines. Feed should not be abnormally dilute, as often happens during start-up, since segregation is thereby increased. When the torque starts to rise, don’t increase the underflow- rate so excessively that the strata of settling fines above the segregated sands are pulled out by rat-holing. Addition of flocculating agents during start-up will alleviate the problem, since they tend to hold the solids structure together and decrease segregation.

Extreme segregating pulps are not common, and all the difficulties described above are seldom met. If in a batch test a gritty layer of segregated solids build up in the bottom of the graduate within an hour or so, one that has to be spooned out of the graduate, such start-up problems should be anticipated.

Follow Orders

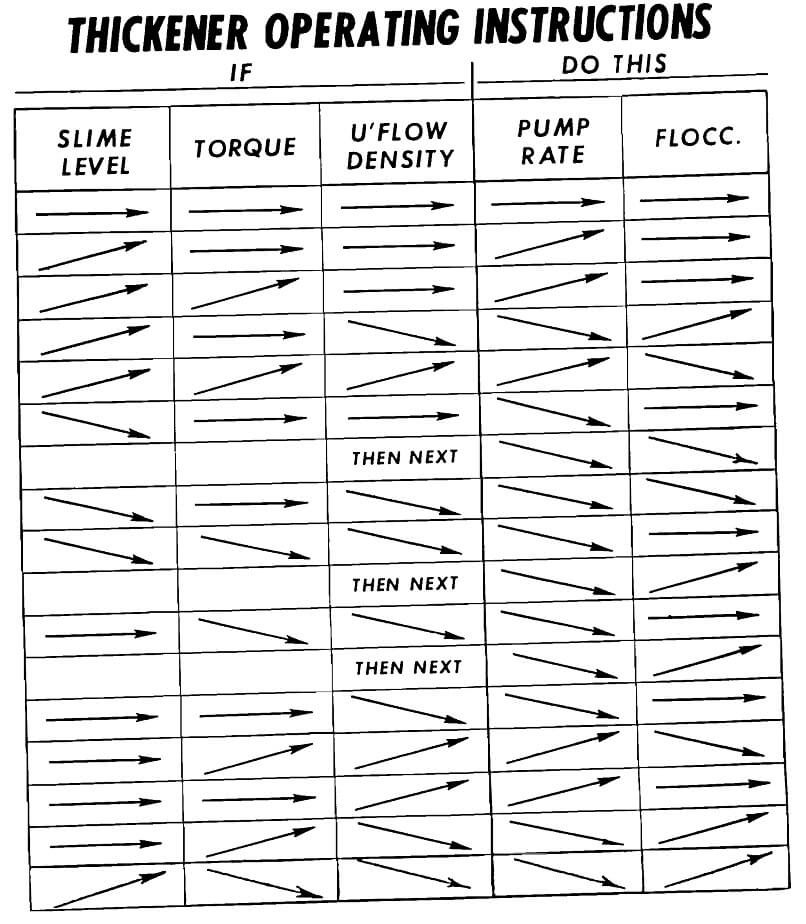

In any case, the shift boss will start you out by showing you, or telling you, how thick the sludge is supposed to be, and all you have to do is to keep it that way. If it gets thinner than it ought to be, slow up the diaphragm pump. If it gets thicker than it ought to be, speed up the pump. As to just how much to change the pump setting, all we can do is tell you to go easy until you learn by experience. If you shift the setting too much, you may run the thickener away over in the wrong direction and then you’ll have to coax it back again. This sort of see-saw operation is bad for any piece of mill equipment, but it is particularly bad in thickeners used in counter-current decantation work. Handling flotation machine upsets is child’s play by comparison, because the thickeners take so long to make up their minds.

What happens if you do let the thickener underflow (the sludge) run too thin? If it is a tailings thickener, you are wasting water, which is unforgiveable in the desert. If it is a concentrate thickener, you . may be handing the filter operator a headache, which he may return with interest. If it is a C.C.D. thickener, you are only making trouble for yourself farther along the line.

Suppose you let the thickener underflow run too thick—what then? You may cause the overflow to become slimy, for one thing, but the big danger is that you may overload the thickener. It was built to handle just so much sludge, and if you crowd it beyond that point, you are in for trouble.

This brings us to the most important indicator of thickener operation, the overload alarm. There is a spring arrangement attached to the drive mechanism up on top in such a way that when the arms begin plowing into sludge more than they were meant to, the spring pulls over a pointer on a scale put up where you can see it. The tougher the going, the more the pointer comes over; until finally a bell rings to warn you to get busy and do something about the overload. If you should leave things alone after that, the pointer moves a little farther, closes a contact, and shuts the thickener down. The fat is now really in the fire. The rake arms are buried in mud, and the feed will have to be cut until the thickener has been unloaded. When unloaded, the arms have to be raised until the thickener mechanism will again turn. Following this, the pump must be speeded up to help draw down the sludge load as fast as possible. While this is going on, the thickener arms must be lowered slowly until they finally reach their normal operation location. And then after you have done probably more than your share of this dirty job, you will be hauled up on the carpet to explain where you were when the bell rang.

And yet there have been thickener operators who stuffed paper in these warning bells because they didn’t like to be startled out of a sound sleep, by loud ringing noises. Just remember that pointer and the bell are there for a purpose, and that

when they indicate an overload, the changes are about 100,000 to 1 that the thickener really is overloaded. You will save yourself an awful lot of trouble by paying attention to these warnings.

For those people who are still operating one of the old-style-hair- on-the-chest belt-driven thickeners, let us add this warning: If your thickener bogs down, there isn’t any fancy cut-out switch, and you may be tempted to start the thickener by main strength. You slap on belt dressing, maybe you even tighten the belt, and give it everything you’ve got. Sure enough, you may get the central shaft to turning, but the rake arms won’t turn. You will discover before long that your strong-arm stuff has turned the central shaft into a poor imitation of a barber pole, which is a very difficult thing to explain away.

What to do when the pointer begins to show an overload? Look at the discharge to see whether or not you are “over-thickening,” which means pumping sludge too slowly. Also, run a pole down into the thickener over near the centre of the tank. You can tell by the feel when the end of the pole reaches the layer of thick sludge. This thick layer ought to be about two feet thick—not much more and not much less. In case of overload, it will probably be more, and you can cut it down by pumping faster. If the slimes are away up, you may be feeding too fast.

In the case of the belt-driven thickener with the stuck rakes, the thing to do is to raise the rakes until they clear the sludge. Instead of slapping on the dope, run them around by hand a complete revolution to make sure they are clear; then start up again, gradually lowering the rakes every hour or so until you work the load off. Never stop the diaphragm pump when the thickener cuts out or gets stuck. If anything, hurry it along.

A Few Other Points

The foregoing are the main items to remember in thickener operation, but there are a few other points worth mentioning. For example, there is this matter of dropping things into the tank. It is a safe bet that there would have been no tool shortage at the beginning of the war if all the thickeners in the country could have been drained and the “lost” tools recovered from them. And what is worse, a tool may be shoved by the rakes over into the center of the tank bottom, where it will jam the outlet and perhaps choke off the sludge. Digging it out is the only remedy, unless you can fish it out; so the moral is, hang onto your pipe wrenches when you work near a thickener.

In a really big thickener, it is sometimes difficult to tell if the arms are moving. Not just for that reason, but because it is a pretty good idea anyway, some companies have had their men fasten a thin pole in an upright position to the end of one rake arm. This pole should be long enough to reach the surface of the water, and on top of the pole is fastened a red ball, a decoy duck, a model of the “Queen Mary,” or whatever you like. Then as the arms go around, the duck goes around, too, and because it is out at the end of the arm, it swims fast enough to leave a wake.

Sometimes a “washboard” condition may develop the thickener gravel roads, and the ‘‘tame duck” will give this condition away instantly by beginning to travel like A porpoise. The washboard effect may sometimes be stopped by changing the speed of the arms, just as you can find a car speed that will stop the bouncing over washboard roads.

Island Formation

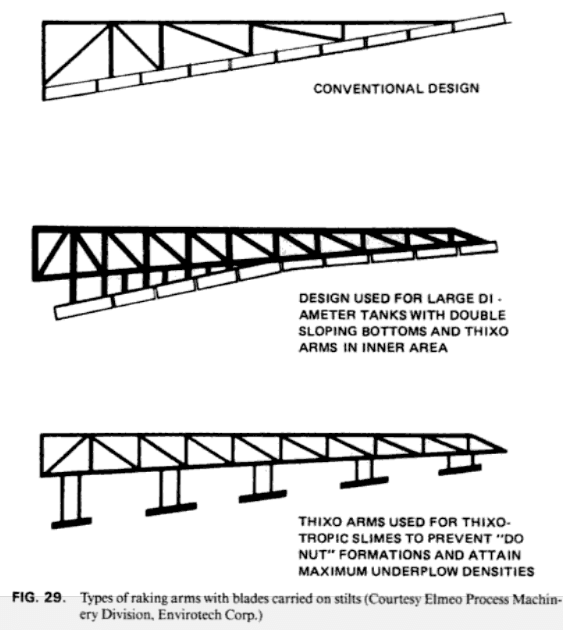

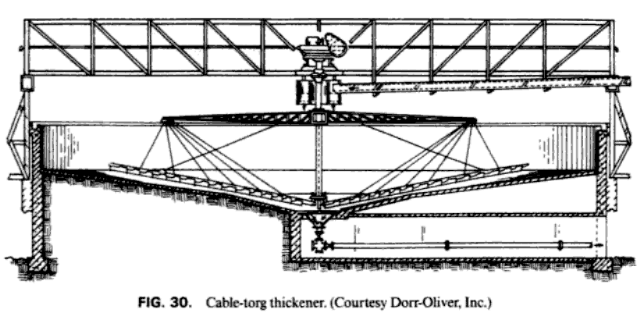

If “islands” tend to form, they can usually be kept under control by raising and lowering the rakes once a shift. If this fails, they can often be broken up without shutdown by poling or by the use of water or air lances. If island formation is anticipated, raking mechanisms with a minimum of structure down in the compression zone should be used. In one class of designs the rake arm is arranged above the mud level and the blades are carried on stilts (Fig. 29). More recently, units have been offered in which the rake arms are a minimal structure and are towed around by cables from rotating drag arms located above the liquid level (Fig. 30).

More recently, units have been offered in which the rake arms are a minimal structure and are towed around by cables from rotating drag arms located above the liquid level (Fig. 30). The arms also raise at high torque. They are pivoted at the center so that the plane defined by the rake arms and the towing cables can rotate hingewise along a line drawn through the central pivot and the cable tow point b. The rake arms thus torque up in an arc whose center is the hinge line. In the original design developed in South Africa, the rake pivot is doubly-hinged to create a universal joint. The rake arm is then free to follow the arc that maintains constant cable length and tensions, while still preventing rotation of the arm and tilting of the rakes.

The arms also raise at high torque. They are pivoted at the center so that the plane defined by the rake arms and the towing cables can rotate hingewise along a line drawn through the central pivot and the cable tow point b. The rake arms thus torque up in an arc whose center is the hinge line. In the original design developed in South Africa, the rake pivot is doubly-hinged to create a universal joint. The rake arm is then free to follow the arc that maintains constant cable length and tensions, while still preventing rotation of the arm and tilting of the rakes.

Cable-towed rakes have proven most advantageous for applications in which scaling is a problem. Their minimal submerged rake structure collects scale at a much lower rate than conventional ones, and they can be operated for substantially longer times between shutdowns for descaling. They are rapidly replacing conventional units for red mud washing in alumina plants, where scaling is severe.

If the sludge slows down or suddenly stops coming into the pump, the pipe is probably plugged. You have no doubt already been shown how to blow air and water through the pipes to clear them. If the pipe doesn’t seem to be plugged, there may have been a “snowslide” of pulp over into the center of the tank, and you may have been the victim of island formation. Islands are big collections of sludge that ride around on the rake arms and refuse to be scraped out of the tank. You can tell by sounding with a pole whether you have a snowslide or an island, and if it is a slide, treat it like an overload. If it is an island, try to break it up by shoving a water jet down into the center of it.

Just a word about thick pulps. Don’t be afraid that a thick pulp will plug up the diaphragm pump or the sludge lines. Actually a thin pulp will plug the line much quicker than a thick pulp will, the reason being that sand settles out of a thin pulp faster than it does out of a thick one. If you try to pump a thin pulp from a thickener, sand may settle out and plug the pipe lines.

This may seem to be rather late in the game to tell you how to start a thickener, but we do want to get it in. Don’t start a nice clean thickener by filling it with fresh water and then running in pulp. If you do, the chances are that sand will settle out so fast in the clear water that it will bury the rakes before they do any raking, and you are licked before you start.

The thing to do is start the arms going with the thickener empty, men run in pulp, and let the thickener fill up with it. Run the diaphragm pump slowly for as long as is necessary to bed the thickener down with a couple of feet of thick sludge, then bring the pump up to what seems to be the proper speed for steady operation.

Now for a few mechanical details, and that will be all. Keep all the bolts tight around the drive mechanism, and clean regularly the screen on the feed launder so that wood chips don’t get into the tank. Waterlogged wood helps form islands. Sluice out the sludge line once a week, and test the overload alarm daily. Keep the worm chamber on the drive mechanism full of oil, and take care of the grease fittings daily. The lifting screw gear ought to be greased well, and it is a good idea to keep grease on the central shaft for about a foot below the worm gear. And don’t fall into the thickener; it doesn’t look well.

How to Operate a Grinding Circuit

How to Operate a Flotation Circuit

This Robert Ramsey article, now in the Public Domain, is based largely on information furnished by C. K. McArthur, of The Dorr Co., Inc., New York, N. Y., and further information and suggestions were furnished by H. L. Hazen and Wayne C. Hazen, of Manganese Ore Co., Boulder City, Nev. Their assistance is gratefully acknowledged.