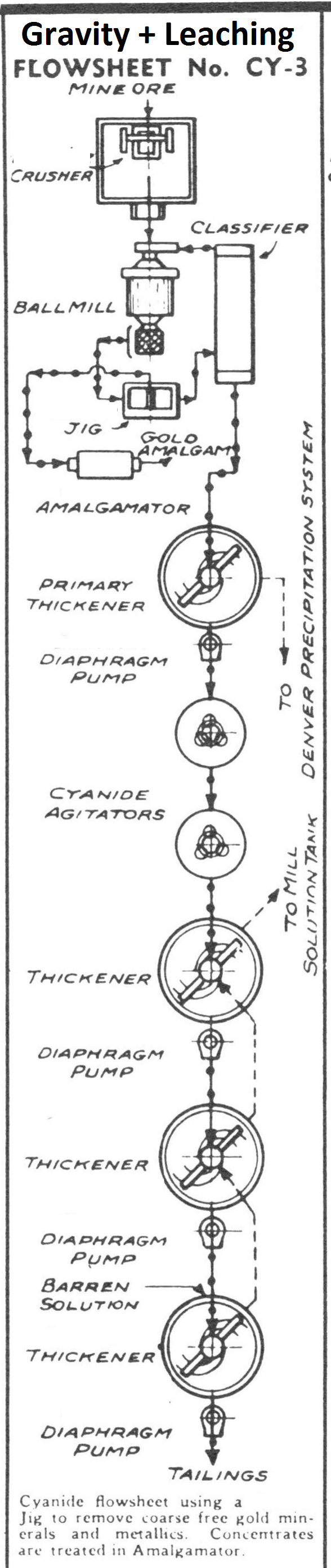

Process Flowsheet NO. CY-3 is shown one of the outstanding improvements made in cyanidation whereby the coarse metallic minerals are removed from the grinding circuit by means of the Mineral Jig. The hutch product from this jig is amalgamated with a Amalgamator or Clean-Up Pan and thus the coarse mineral values, such as metallic gold, are removed from the circuit before complete fine grinding takes place. This jig hutch product containing most of the fine as well as the coarse metallics, can also be treated by a separate grinding and cyanide treatment plant. This Jig, due to its synchronized valve action, requires the minimum amount of water. Its feed and discharge elevations are sloped as a launder, so that pumps or elevators are not required.

By the early removal of the coarse gold and other minerals, it is possible to materially reduce the chemical consumption in the cyanide plant and also the time required for agitation, as well as offering the possibility of grinding at a coarser mesh. In other words, the removal of a certain portion of the minerals at a coarse mesh, and their separate treatment, either by amalgamation or by a small cyanide plant, eliminates the necessity of fine grinding the entire tonnage to recover the values from this small portion of the ore that often contains the majority of values.

The balance of the circuit is then similar to that shown on Flowsheet No. CY-1, with the advantages, however, of lower chemical consumption and a lower agitating time, with less equipment needed for final thickening and filtering. This is due to the high efficiency of the Mineral Jig in removing not only the coarse values that are free and that would require additional time and equipment, but also in removing most of the middling values that would require finer grinding of the entire ore with the resulting higher equipment and operating costs.

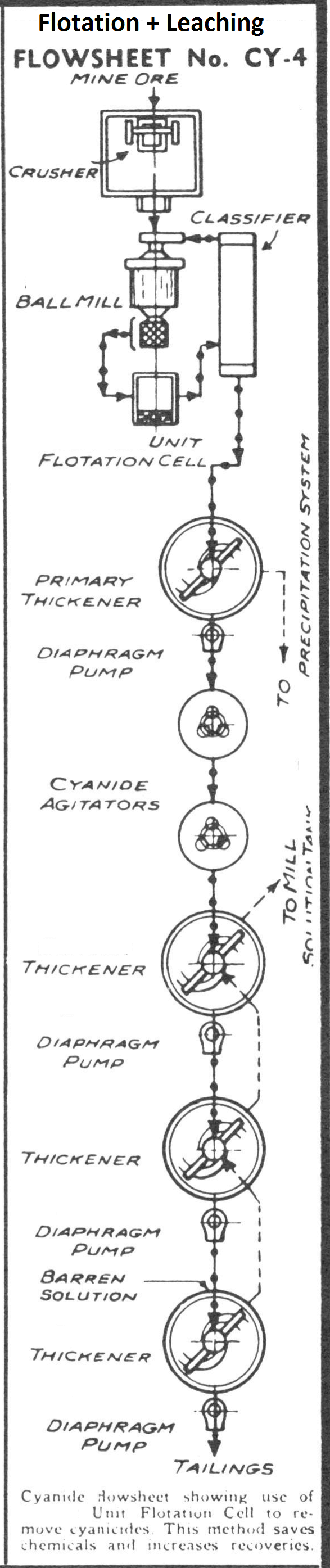

Process Flowsheet NO. CY-4 is similar to Flowsheet No. CY-3, excepting that a Unit Flotation Cell is used between the ball mill and the classifier to remove cyanicides or harmful elements from the cyanide circuit, thus preventing an excessive chemical consumption. This concentrate produced on the Unit Flotation Cell can be sent to a smelter or treated separately from the balance of the cyanide circuit. This method of treatment has been proved distinctly advantageous and should have an important application on ores where copper and other cyanicides are present. Flotation chemicals or reagents used in the Unit Flotation Cell do not affect the subsequent treatment by cyanidation.

In many instances this Unit Flotation Cell, due to the additional aeration secured, plays an important part in the chemical reaction between the cyanide and the gold and silver values. In the cyaniding of silver ores it is essential to have ample air and therefore the air that is introduced in the Unit Flotation Cell and in the Super-Agitators, is very important.

These flowsheets are widely used for the treatment of average ore by the cyanide process and indicate the improvements which can be made.