Gravity tests, also known as gravity separation tests, are used to determine if a constituent, especially gold, can be concentrated by exploiting differences in density, shape, and or size between the constituent of interest and the waste material (gangue). 911 Metallurgy specialists have extensive experience in gravity processing and can provide you with the gravity concentration services you need.

Why use gravity concentration?

Gravity concentration is often an effective and economic unit operation, with low capital and operating costs. The process can also be environmentally favorable, as little to no reagents are used in the process. 911 Metallurgy can help you determine if your ore process could benefit from gravity concentration.

What are the different types of gravity test equipment available?

There are many different types of equipment that can be used for gravity separation including but not limited to:

- Cyclone Separation

- Dense Media Separation

- Hand Panning

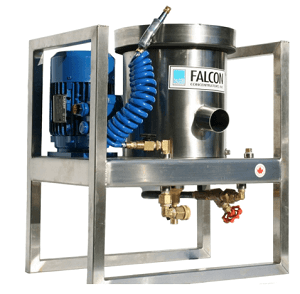

- Falcon Concentrator

- Knelson Concentrator

- Jigging

- Spirals

- Wilfley Tables

911 Metallurgy specialists have extensive experience with all types of gravity concentration equipment and will help you optimize your process with the equipment best suited to your ore.

What is a gravity test?

Gravity test procedures can vary depending on the type of equipment being used. Generally, a known amount of material is processed by the gravity concentration equipment, resulting in a concentrate and tailings product. The concentrate and tailings are then weighed, dried, and assayed to determine final constituent mass balances and recoveries. 911 Metallurgy specialists have experience with all types of equipment and will tailor your testing program based on your ore.

How can I optimize recoveries?

Gravity separation recoveries are often significantly impacted by the feed size of the material. Additionally, 911 Metallurgy specialists can also provide extended gravity recoverable gold testing and gravity process circuit modeling.