The furnace used for melting gold bullion is of simple construction. It may be round or square, with walls consisting of an outer layer of ordinary brick and an inner layer, at least 4 inches thick, of the best firebrick. There is often a complete outer casing of iron, which is useful in keeping the furnace from falling to pieces, but radiates more heat than the bricks. The fire-box in a small furnace may be about 1 foot square and about 2 feet deep; below it is an ashpit, usually lined with a cast-iron tray and provided with a working iron door, through which the air-supply of the furnace passes, and by which it is regulated.  The largest furnaces at the Mint are round, 21½ inches in diameter and 31½ inches deep. Still larger furnaces are in use at the Rand. The fire-bars are movable, and their ends rest loosely on iron supports.

The largest furnaces at the Mint are round, 21½ inches in diameter and 31½ inches deep. Still larger furnaces are in use at the Rand. The fire-bars are movable, and their ends rest loosely on iron supports.

The top of a Gold Melting Furnace may be made flat or sloping up towards the back at an angle of about 30°. In this case a wide flat ledge should be provided at the front, on which crucibles and moulds can rest.

The top is always made of a cast-iron flanged plate, with an opening of the same area as the fire-box. This opening is closed by a cast-iron sliding door made in one or two pieces, and preferably lined with firebrick and running on rollers. The flue is placed at the back of the fire-box near the top ; in a small 12-inch square furnace the cross-section of the flue should have an area of about 16 or 18 square inches—6 by 3 inches, and 4 inches square are both convenient sizes. The round furnaces at the Mint have a flue of 6 inches square. The flue communicates with a stack, which must be of brick for a distance of 2 or 3 feet from the furnace, but may be of wrought-iron tubing in its upper part.

The height of the stack will depend on the position of the furnace, and should be as great as possible, 60 feet giving better results than any less amount. It has been stated that a height of 30 feet is the minimum that can be allowed in order to ensure a good draught, but very satisfactory results can be obtained with a stack only 16 feet high. The furnace can be built by any bricklayer acting under directions. No mortar is used in its construction ; clay, mixed with an equal bulk of sand, being substituted for it. A sliding damper in the flue at a convenient height above the ground is necessary, so as to regulate the draught. The fuel used in such a furnace may be anthracite, charcoal, or good coke, made in coke ovens, and broken into pieces of moderate size.

If the coke is of high quality, it is the most satisfactory fuel, making a hot fire and lasting for a long time, so that it does not require very frequent replenishing. Neither dust, nor very small, nor very large pieces must be used. Charcoal is preferred in the United States Mints for small charges, and anthracite for large ones.

Gas furnaces are also used, the crucible being heated by three or more burners, each with a blast of air, placed at regular intervals in the circumference. Gasoline or naphtha furnaces are also in use.

The flues should pass into dust chambers. At the Mint the dust chamber is 12 feet high, 1 foot wide, and of the same length as the row of furnaces, and at the Melbourne Mint the dust chamber is 8 feet high and 5 feet wide. Baffle plates should be inserted in the dust chambers, which are built of brick.

What Furnace is best to Melt Gold

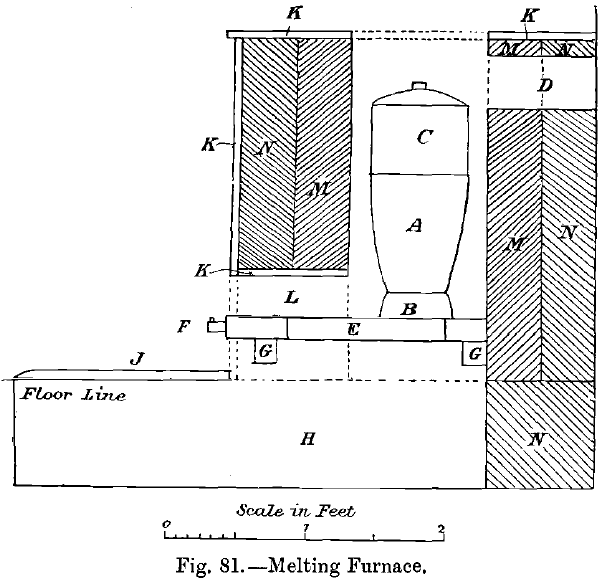

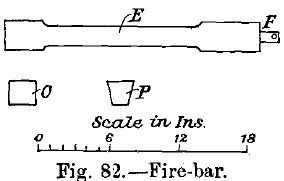

One of the gold melting furnaces in use at the Royal Mint, London, is shown in sectional elevation in Fig. 81, and a fire-bar belonging to the furnace is shown in Fig. 82. The crucible A stands on B, which consists of the lower part of an old plumbago pot cut off about 2 inches from the bottom. C is the “muffle,” a plumbago cylinder 6 inches high, resting on the crucible. It enables a deeper bed of coke to be used, and also gives space for charging-in bulky material. The furnace is 12 inches square and 2 feet deep above the fire-bars. The pot is 8 5/8 inches diameter at the widest part, and its charge is 1,200 ozs. of standard gold. The flue D is 4½ inches deep and 5 inches wide, and communicates with a stack 45 feet high. The fire-bars, E, are 22½ inches long and 2 inches deep. They are tapered downwards, especially in the middle portion. The section of the thick part near the ends is shown in O, Fig. 82,. and that of the middle part in P, Fig. 82. The projection F is used for withdrawing the bars. G G, Fig. 81, are the supports for the bars; they are of

The crucible A stands on B, which consists of the lower part of an old plumbago pot cut off about 2 inches from the bottom. C is the “muffle,” a plumbago cylinder 6 inches high, resting on the crucible. It enables a deeper bed of coke to be used, and also gives space for charging-in bulky material. The furnace is 12 inches square and 2 feet deep above the fire-bars. The pot is 8 5/8 inches diameter at the widest part, and its charge is 1,200 ozs. of standard gold. The flue D is 4½ inches deep and 5 inches wide, and communicates with a stack 45 feet high. The fire-bars, E, are 22½ inches long and 2 inches deep. They are tapered downwards, especially in the middle portion. The section of the thick part near the ends is shown in O, Fig. 82,. and that of the middle part in P, Fig. 82. The projection F is used for withdrawing the bars. G G, Fig. 81, are the supports for the bars; they are of

2-inch square iron, and let into the brickwork. H is the ashpit, 12 inches by 3 feet 4 inches and 9 inches deep below the floor. It is lined with ¾-inch cast-iron plates. J is a sliding iron plate covering the exposed part of H. KK are cast-iron plates ¾ inch thick covering the furnace. There are four fire-bars and their thickened ends nearly touch, occupying 11 inches in the width of 12 inches. The spaces between the middle parts of the bars, however, are over ½ inch wide, and some air passes in between the bars, but most of the air enters the furnace through the aperture L which is 3½ inches high above the fire-bars and 12 inches wide. The pot-support B rests on the two middle fire-bars, so that the outer fire-bars can be withdrawn without disturbing the pot. The furnace is lined with firebrick, MM, 4½ inches thick, the outer layers N being filled up with ordinary brick. The top of the furnace is 29 inches above the floor line. A row of eight furnaces have one stack in common. The distance between the centres of two adjacent furnaces is 2 feet 6 inches.

Melting Furnace Crucibles

The bullion is melted in either graphite or clay crucibles, or in graphite pots lined with clay. Detachable clay liners are sometimes used, or a clay pot may be fitted inside a graphite guard pot. The size of the crucibles and the weight of the charges of bullion vary greatly, but in extraction mills, as a general rule, a gold-charge does not exceed 400 ozs., and a silver-charge 1,200 ozs. in weight. In mints and refineries, much larger crucibles are employed, holding different amounts up to 6,000 ozs. of metal On the Rand No. 400 pots are used in certain cases, capable of holding 12,000 ozs. of metal.

Melting Gold Bullion

All crucibles must be thoroughly annealed before being used; otherwise, the contained moisture being suddenly converted into steam when the crucible is heated rapidly, the pots crack. The crucible is kept on a shelf near the flue, for as many days or weeks as convenient, before being used. It is then placed on the top of the furnace or in the ashpit for a few hours, when it will probably be safe to hold it over the open furnace by means of the crucible tongs, until it becomes gradually warm. After a few minutes, the crucible being turned round at intervals, it can be lowered rim downwards upon the burning fuel, and as soon as the rim becomes red-hot, the crucible is quite safe, and may be turned over and placed in position for the reception of the gold. With Salamander crucibles, a less degree of care in annealing will suffice, as they are well annealed before being sold. The crucible rests on a firebrick about 3 inches thick, which is laid on the bars of the grate. If the firebrick were omitted, the bottom of the pot, resting directly on the fire-bars, would be too cold, while a layer of fuel, if placed below the pot, would soon be burnt out, and could not readily be replaced, so that the pot would sink down to the bars.

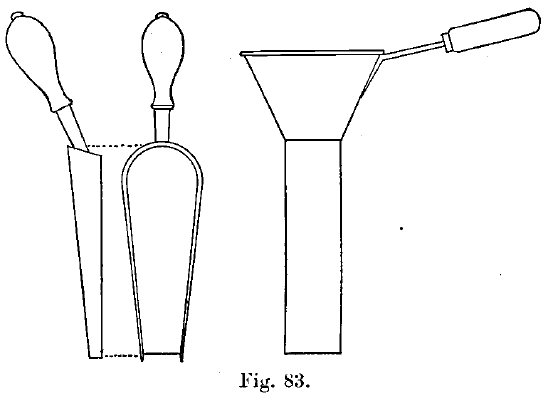

The fuel is built up round the pot until it reaches to its rim, or the top of the muffle furnace, and the fire urged until the whole pot is at a full red heat. Borax is then thrown into the crucible by means of a scoop to slag off metallic oxides and so assist the metal to melt. As soon as the borax is melted, the introduction of the bullion is commenced. The safest way to do this is to use the shoot shown in Fig. 83, which is held in position, its lower edge being inside the crucible, with the left hand, while the metal is transferred to it in a scoop by the right hand. In this way the melter avoids all danger of loss which might be encountered if the metal scrap were wrapped in paper and added by the tongs. Large pieces of metal are added by the crucible tongs. The cover, which must also have been previously well annealed, is kept on the crucible as much as possible, and the fuel pushed down with the poker to avoid scaffolding, and fresh pieces of coke added when required. The crucible is not allowed to become more than two-thirds full at any time, but more metal is added when the first supply has been melted down, and the operation repeated until the pot is sufficiently full of molten material.