There are two kinds of sample salting: intentional and innocent. Intentional salting can be defined as the surreptitious addition of valuable material to a sample with intent to deceive. Innocent salting, which can have the same end effect, can be accidental or the result of carelessness or improper working procedures. Although intentional salting is seldom encountered, only the engineer who is constantly alert can feel secure about his sample results. A few of the salting methods applicable to trenches are:

- Adding gold in the material to be sampled.

- Placing gold in sample containers or in the sample itself.

- Adding gold in the excavating or washing equipment.

- Dropping bits of gold in the pan during final processing.

Where the volume of material obtained from a drill hole or from a channel cut is comparatively small it takes very little gold to appreciably alter the value. It should be noted that in bulk sampling a substantial amount of gold may be required to achieve the desired effect but, at the same time, the opportunity for salting may be greater. This is because the larger the sample the more it is handled, and the more it is handled, the more difficult it becomes to provide adequate safeguards or keep it under constant surveillance. Ironically, it may be easier to detect salting after it has happened than to prevent it in the first place.

But there are many precautions that can be taken to discourage salting, most of which require little more than common sense. Some are:

- Keep the exact location of the point to be sampled a secret until the actual cutting begins.

- Clean and carefully inspect all faces before sampling.

- Clean and carefully inspect all equipment before sampling.

- Check equipment at appropriate intervals.

- Complete the cutting and processing during a single work-day if possible.

When sampling is completed, go back and take a few check samples from selected points particularly those showing unusually high values.

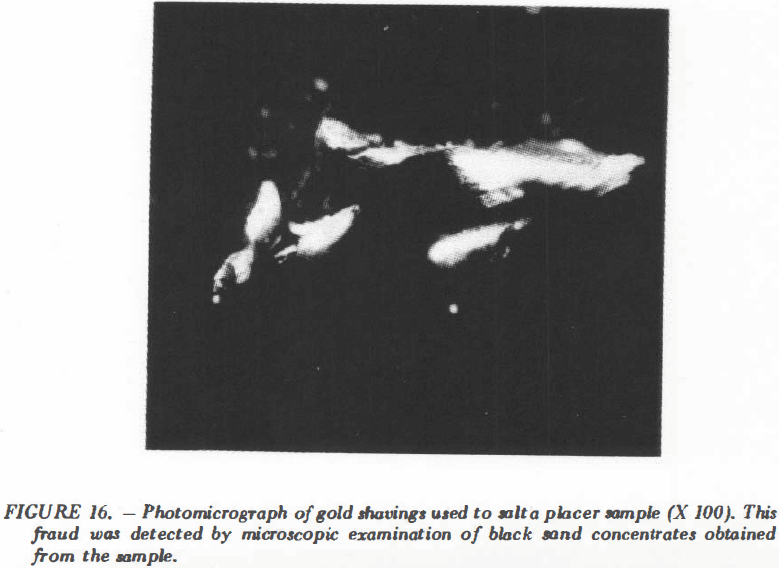

Some placer drillers place barren material in the bottom of the drill hole at the end of the shift and test it for values when resuming operations. The black sand concentrate obtained from a sample should be examined with a hand lens or preferably, with a low-power microscope because at this point the careful observer can usually detect any anomalous or foreign material in the sample. Figure 16 is a photomicrograph showing gold shavings found in a placer sample. In this case, the shavings were small enough to be missed in a cursory inspection of the pan concentrate but examination under a 20X binocular microscope revealed the fraud.

Another give away may be sample results that are consistently too high or too regular in value. The mineral examiner should always compare his sample results with the known or expected tenor of the district and where marked discrepancies appear, the cause should be ascertained.

While the possibility of samples being tampered with must never be disregarded, the possibility of the sampler “salting” himself through carelessness or through use of an incorrect procedure is usually much greater.

What Salting can do

When Acquiring Good Samples is Difficult to Impossible

Not all placers lend themselves to the usual forms of sampling and there are some which cannot be sampled by any means short of mining the entire deposit. This problem usually reflects one of two things:

- The gold or other mineral occurrence is so erratic that usual sampling or evaluation methods break down hopelessly.

- There are physical conditions which make sampling impracticable

Excellent examples of the latter condition can be found in California’s drift mines. Sampling problems inherent in this type of deposit have already been brought out under the heading of “Drift Mine Sampling” but the point to be made here is that the physical characteristics of such deposits when combined with an almost complete absence of surface guides to their underground location makes sampling in the normal sense impracticable. Historically, the successful exploration and development of this type of deposit has relied on the practical application of bits and pieces of information gleaned from limited surface exposures or underground workings. This is another way of saying the old-time drift miner relied largely on geologic inference tempered by good judgement. Today’s mineral examiner, when confronted by a deposit that cannot be readily sampled, may also have to fall back on his powers of observation and other resources.

Where factual sample data cannot be obtained without extensive and costly explorations, which except in isolated cases will probably never be made, authentic production records will generally be found a useful source of information. And even where the actual records are not available, it may be possible to obtain enough statistical information from state mining bureau reports or other government publications to ascertain the past production of better-known mining districts and to appraise their remaining potential. To varying degrees, this type of statistical data can be applied to individual properties. Noteworthy examples are found in studies of California’s hydraulic mine reserves carried out by State and Federal agencies, preparatory to construction of the North Fork and Yuba Narrows debris retention dams.

But, the point to be stressed is that sooner or later the mineral examiner can expect to encounter a placer deposit where sampling fails and when this happens, it is important that the fact be recognized.