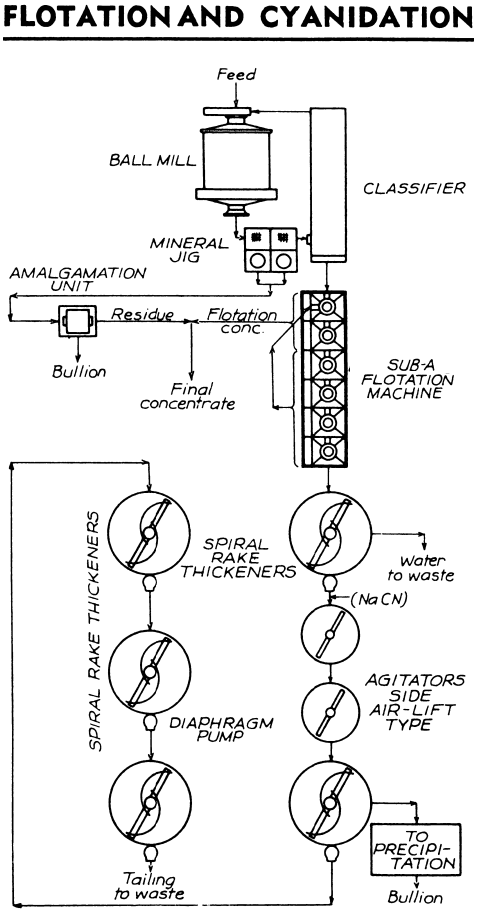

DESCRIPTION: Flotation with cyanidation of flotation tailings. This flowsheet has a gravity gold recovery embedded into the grinding circuit’s ball mill discharge.

ORE TREATED: Ores containing both oxide and sulphide minerals with gold or silver, or those with cyanicides which must he removed before cyanidation.

ADVANTAGES: This flowsheet makes possible the milling in one plant of two types of ore, oxide and sulphide. The oxide ore may lie readily cyanided but not floatable. The sulphide ore may float readily, but due to the contained copper or other cyanicides it is not amenable to cyanidation.

In several cases, cyanicides have interfered with the operation of the cyanide plant and the addition of flotation for removing these has been very successful. In other cases, the economic advantages of cyanide treatment have been made possible on low copper ores by selectively floating a high grade copper concentrate for shipment to the smelter and rejecting a high gold tailing from which the gold is recovered in bullion form through cyanidation.

PROCESS COMMENTS: This flowsheet may be applicable in other cases, also, as for example, on a sulphide ore with galena, wherein the lead values could be recovered and shipped to the smelter. In some ores containing pyrite, this pyrite fraction requires finer grinding than does the quartz or other fraction of the ore for maximum recovery, by cyanidation. In this case, it might be advisable to remove this pyrite by flotation, (see this Flowsheet) or by a Mineral Jig for regrinding or roasting prior to cyanidation.