For Sale is a MAS Series Industrial Fire Assay Furnace – Cupellation Assay Furnace, Fusion, Globar Elements

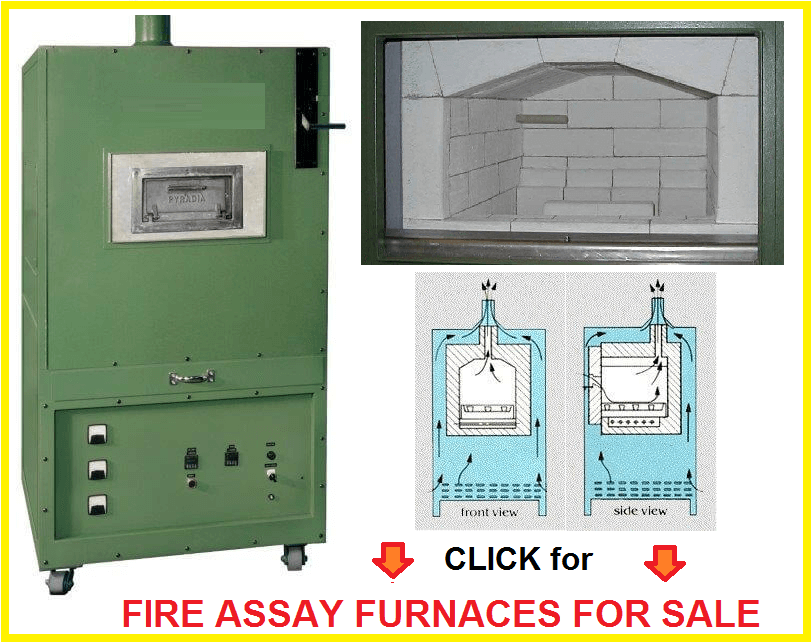

The Mine Assay MAS-series fire assay furnace (formerly known as “Williams & Wilson”) is well known in the mining industry all across North America, as well as in other locations worldwide. Solid construction, durable features, and dependable, continuous operation have allowed it to become the criterion for quality for over 50 years while continuing this standard of excellence with ongoing technical improvements.

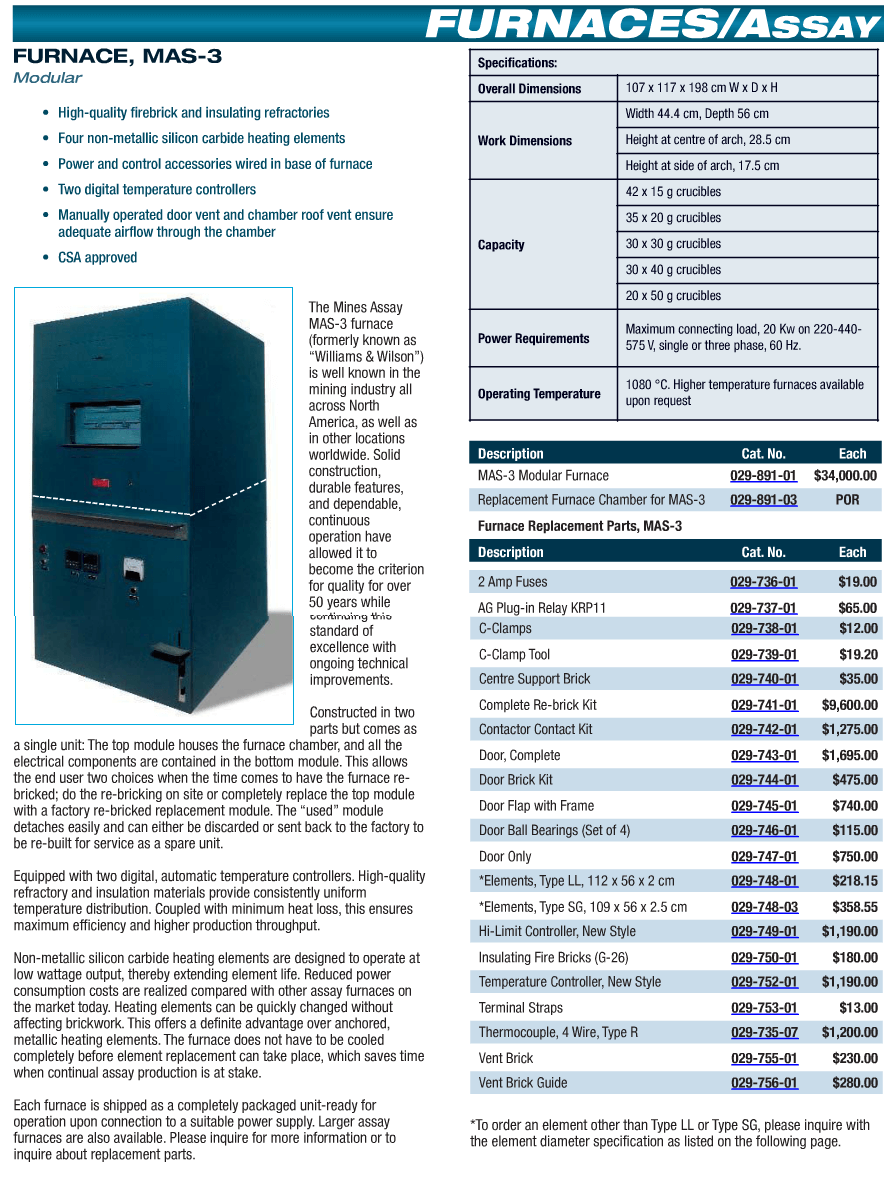

- Replacement Cost: $34,000

- POWER: 22 kW / 460 Volts / Three Phase / 60HZ

- High-Quality Firebrick and Insulating Refractory

- Four GLOBAR SG-Series Non-Metallic Silicon Carbide (SiC) Heating Elements

- Maximum Element Temperature: 1650°C (3000°F)

- Power and Control Accessories Wired in Base Of the Fire Assay Furnace

- Two Digital Temperature Controllers

- Manually Operated Door Vent and Chamber Roof Vent Ensure Adequate Airflow Through The Chamber

Furnace Interior: 444 mm Wide x 560 mm Deep x 285 mm High

Overall Dimensions: 57″ Wide x 48″ Deep x 85″ High

Weight: 2,205 lbs

Constructed in two parts but comes as a single unit: The top module houses the Fire Assay Furnace chamber, and all the electrical components are contained in the bottom module. This allows the end user two choices when the time comes to have the furnace re-bricked; do the re-bricking on site or completely replace the top module with a factory re-bricked replacement module. The “used” module detaches easily and can either be discarded or sent back to the factory to be re-built for service as a spare unit.

The Fire Assay Furnace is equipped with two digital, automatic temperature controllers. High-quality refractory and insulation materials provide consistently uniform temperature distribution. Coupled with minimum heat lost, this ensures maximum efficiency and higher production throughput.

Kanthal’s GLOBAR non-metallic silicon carbide heating elements are designed to operate low-wattage output, thereby extending element life. Reduced power consumption costs are realised compared to other assay furnaces on the market today. Heating elements can be quickly changed without affecting brickwork. This offers a definite advantage over anchored metallic heating elements. The furnace does not have to be cooled completely before element replacement can take place, which saves time when continual assay production is required. Each furnace is shipped as a complete package unit, (Still in its Original Crate) ready for operation upon connection to a suitable power supply.

No crating or loading charges.