Fire Assay Cupels: Calmix, Machine Made—Under the process of manufacture, the material used produces a cupel uniform in density and power of absorption with a firm and glossy surface that will not crack nor check. They embody the following advantages :

- Need no initial drying.

- Absorb more lead than bone ash.

- Greater absorbing power permits the use of smaller cupels.

- Greater conductivity makes them respond quickly to temperature regulation and permits exceptionally close control of cupellation.

- Are uniform in size, appearance and performance.

- Are hard, packed securely, and will stand the roughest kind of transportation.

- The cupellation losses are much less than with bone ash cupels due to the better conductivity of the material.

Calmix cupels do not require the careful drying of other cupels. Try this severe test. Place a calmix cupel in a beaker of water. Take it out and without drying, put it in the muffle. The button will cupel perfectly during Fire Assay.

Caution: While calmix cupels are harder and will withstand shipment better than bone ash cupels, it will be found out that when hot in muffle, they are softer and therefore require more careful handling than bone ash cupels.

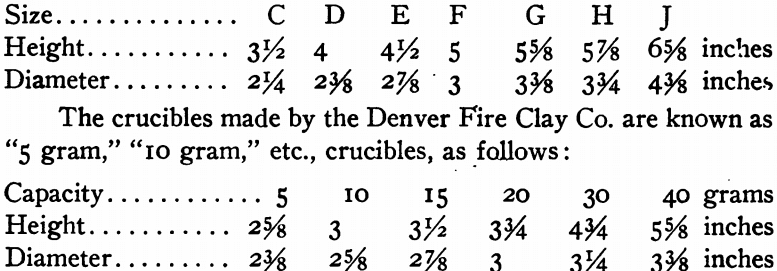

CUPEL MOLD, Hand—Consists of a heavy cylindrical iron cup and a solid iron die which fits the inside of the cup closely. Used for compressing bone ash or substances of similar nature into cupel form for assaying.

CUPEL MACHINE, Foot Pedal—A fast machine, capable of producing 500 cupels per hour. The pedal operation leaves both hands free for handling the bone ash. The density and thickness of the cupels are controlled by one set-screw in the pedal, which is easily adjusted. All dies are brass, and a change of dies takes only a minute. Built for either two or four sizes of dies. Shipping weight 40 pounds. For 1¼ and 1½ inch cupels.

CUPEL MACHINE, Table Pattern, Braun—This machine produces perfect cupels, is simple in construction and easily operated. The compressing power is obtained by a series of levers which multiply the applied power about twenty times. This machine is made with interchangeable molds and dies. In ordering, please mention the size or sizes wanted. Length, 24 inches; width, 16 inches; height, 19½ inches.

It is apparent that the results of this investigation cannot be reduced to any hard and fast conclusions.

In assaying high-grade products giving large assay buttons, the following general conclusions may be drawn: Within wide limits the screen composition of the bone ash is not the dominant factor in cupellation, but the assayer should inform himself as to the grades of ash available and adopt some plan in selecting or mixing his ash. In the same way, the pressure used in making cupels is not highly important, although it is well to keep it fairly uniform. There is no necessity to season cupels. In making comparative tests, the closest attention must be given to the temperature question, but the temperature of the cupelling bead is for the present beyond either measurement or control, and high general temperature in the muffle may produce wide variations in the absorption of gold in adjoining cupels. The pyrometer is a good guide to the general temperature conditions, but uniformity of pyrometer reading does not mean uniform bead temperature.

In assaying ductile fine gold, for instance, it is evident that the gold absorption by a cupel may be kept down to 0.1 mg. and need not exceed 0.2 mg. Certainly an absorption of over 0.25 mg. should not be countenanced in fine-gold assaying. That these figures are attainable in regular work is shown by the results obtained in laboratory No. 5, which is a large and busy commercial laboratory. In the case of coin gold the figures might be increased by 0.05 mg.

There is no apparent relation between the absorption of the two precious metals and much more work is required to establish facts regarding the absorption of silver.

The careful assayer should establish standards of cupellation suitable for his particular lines of work and should assay his used cupels from time to time to see that the standards are being maintained.

Crucibles, Scorifiers and Cupels

Crucibles for the assay of gold, silver and lead ores are made of fire clay. They are made in two forms, round and triangular. For an ordinary crucible charge of one assay ton of ore and fluxes a crucible 5 inches high and 3 inches in diameter can be used. The Battersea crucibles go by letters as follows:

A low form 30-gram crucible 3 7/8 inches high and 3½ inches in diameter, is also obtainable for fusions made in a small muffle.

Scorifiers are made of fire clay and run in sizes from ½ inch to 4 inches in diameter. Those 2¾ or 3 inches are most used and are suited to changes from 1/5 to ½ assay ton. For scorification and to reduce a too large lead button the 2¼-inch size is well suited.

Cupels are made of bone ash and may be made by the assayer himself or they may be purchased. A cupel should be about 1 1/3 times the weight of the lead button to be cupelled. A cupel 1½ inches in diameter is a good size.