Table of Contents

Whether you’re sampling for exploration, development or production, getting asset data is a critical part of your workflow. Traditionally, it can take weeks to access this data, causing delays and drastically affecting productivity.

Portable XRF Gun X-ray technologies have made it possible to achieve real-time chemical and elemental analysis in the field, but despite all of the hype, they’ve never reached their full potential. Portable XRF is a terrific technology but the problem is the industry treats it as a point solution. This leads to problems with using the technology effectively in the field to generate good data at the point of sample measurement, and also managing the data after it’s been collected. We recognize this and we also recognize that using these machines effectively is not just about the gun.

There are four barriers that have been holding XRF Guns back from reaching its full potential within the industry:

- Lack of training for using the technology effectively;

- Challenges with managing data once generated;

- Complications with global logistics and transport of radiology equipment;

- High upfront cost to access XRF technology.

We created an XRF package to overcome these barriers and provide XRF technology that can deliver the full value it was designed for.

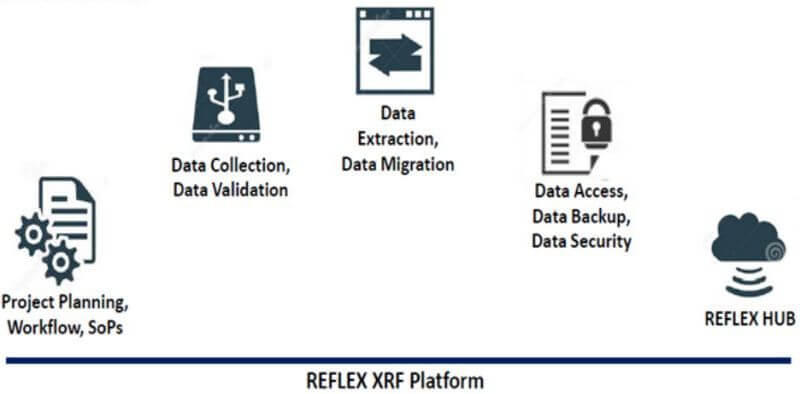

Firstly, we’ve reinvented the interface and written our own software to ensure that optimal readings are taken every time. This means that technology is available to geologists but also drilling and field crew. Secondly, the data generated by the XRF gun is validated in the field at the point of data collection, transmitted to XRF Hub and is then available in real time to geologists anywhere in the world. Once in the Hub, the XRF data can be used in conjunction with other data types, such as your geological logging, survey or orientation data.

So, now we can see it being used in the field, how do you get it there? As an industrial radiology device, the XRF unit can be difficult to transport across state and country borders due to strict policies from customs with this type of equipment. With our global network of Reflex offices and distributors, you don’t need to worry about all of those transport and logistics problems. Making our XRF readily available is the third way we’ve improved the technology. The fourth way we improved the XRF is to make it available for hire, which makes it even more accessible for you.

XRF SOLUTION FEATURES

By automating the time consuming processes such as QA/QC, data validation, database cleaning and formatting, geologists have more time for geology.

Project planning, workflow and Standard Operating Procedures

The XRF Gun solution automates vital processes to ensure data quality and data interoperability within multiple existing platforms. The XRF Gun software has been optimised for geological applications. Workflow, operating procedures and parameters have been standardised within the software to simplify sample collection and ensure data quality and productivity is maximised. Real-time monitoring also allows QC data to be assessed as the data are generated.

Data collection and validation

The XRF Gun solution allows you to configure the operating parameters [count time optimisation, mode and beam settings] and design your own project specific data validation (QA/QC) rules. These rules are built into the data collection routine with immediate feedback on instrument values outside acceptable ranges on blanks, standards and duplicates. The XRF Gun solution allows users to rectify data quality problems at the time of collection rather than when it is too late.

Data access, backup and security

The XRF solution allows users to upload files into HUB, data can then be accessed through the internet from any networked device. Secure, multiple access to the data reduces the risk of error, mismanagement and duplication. The data backup in HUB includes the raw data spectrum and machine state information which is invaluable where data is in doubt as it reveals other matrix and operational conditions that may impact on the data.

The Geochemistry Team is highly experienced in spectral analysis and can provide the most comprehensive and reliable information about your data.

Data extraction and migration

Data is retrieved from the XRF unit in a structured way for further processing and/or storage without multi-handling of the dataset. Data from multiple XRF units are aggregated automatically without duplication. Results may be accessed through HUB from any internet connection for further processing and advanced modelling in software platforms such as ioGAS and Leapfrog.

HUB

The cloud computing environment offered by the HUB allows customers to develop a common operating solution. Within the HUB, data are transformed into information and delivered in near real time, in a unified format, to decision-makers.

| STANDARD ACCESSORIES

CONNECT XRF SOFTWARE

|

CERTIFIED REFERENCE MATERIAL [CRM] KIT

We provide a customised Certified Reference Material [CRM] kit with each XRF instrument. One kit of the customer’s choice is included in each rental and additional kits can be purchased if required.

The kits use Ore Research CRMs and are customised for particular commodities.

Each kit includes 14-15 CRMs. All kits include a silica blank and 6 low level soil and lithochemical CRMs [Group 1]. The remaining CRMs in the kit are selected for specific commodities [Groups 2-7].

CRM certificates of analysis and MSDS sheets are supplied on a USB memory key with the instrument.

BLANKS, LITHOCHEM AND SOIL CRMS.

These are included in all CRM kits.

| CRM_ID | Description |

| OREAS22d | Quartz matrix blank (multi-element) |

| OREAS24b | Granodiorite goechem blank |

| OREAS25a | Soil geochem blank |

| OREAS24c | Basalt lithogeochem blank |

| OREAS45d | Anomalous ferruginous soil |

| OREAS45e | Anomalous ferruginous soil |

| SiO2Blank |

FE ORE

| CRM_ID | Fe_% | Description |

| OREAS401 | 45.63 | Hematite Ore |

| OREAS402 | 48.41 | Hematite Ore |

| OREAS403 | 52.30 | Hematite Ore |

| OREAS404 | 55.10 | Hematite Ore |

| OREAS405 | 58.00 | Hematite Ore |

| OREAS406 | 61.44 | Hematite Ore |

| OREAS40 | 66.72 | High grade Hematite ore |

COPPER-GOLD (INC PORPHYRY AND EPITHERMAL)

| CRM_ID | Cu_% | Au_ppm (for reference only) | Description |

| OREAS501b | 0.26 | 0.248 | Porphry Copper-Gold-Molybdenum |

| OREAS502b | 0.773 | 0.494 | Porphry Copper-Gold-Molybdenum |

| OREAS503b | 0.531 | 0.695 | Porphry Copper-Gold-Molybdenum |

| OREAS504b | 1.11 | 1.61 | Porphry Copper-Gold-Molybdenum |

| OREAS901 | 0.141 | 0.363 | Low grade transitional oxide copper-gold |

| OREAS902 | 0.301 | Low grade transitional oxide copper | |

| OREAS903 | 0.652 | Medium grade transitional oxide copper | |

| OREAS904 | 0.612 | 0.045 | Medium grade transitional oxide copper |

LEAD ZINC

| CRM_ID | Pb_% | Zn_% | Comment |

| OREAS36 | 4.22 | 0.553 | Low grade zinc ore |

| OREAS37 | 6.3 | 0.597 | Medium grade zinc ore |

| OREAS38 | 9.99 | 0.56 | High grade zinc ore |

| OREAS131b | 3.05 | 1.9 | Galena, Sphalerite, Pyrite and Pyrrhotite |

| OREAS132b | 5.19 | 3.88 | Galena, Sphalerite, Pyrite and Pyrrhotite |

| OREAS133b | 11.62 | 5.2 | Galena, Sphalerite, Pyrite and Pyrrhotite |

| OREAS134b | 18.12 | 13.2 | Galena, Sphalerite, Pyrite and Pyrrhotite |

URANIUM

| CRM_ID | U_ppm | Comment |

| OREAS100a | 235 | IOCG – granitic and haematitic breccia |

| OREAS101b | 396 | IOCG – granitic and haematitic breccia |

| OREAS102a | 662 | IOCG – granitic and haematitic breccia |

| OREAS105 | 532 | |

| OREAS120 | 40.8 | Karoo sandstone-hosted tabular deposit |

| OREAS122 | 418 | Karoo sandstone-hosted tabular deposit |

| OREAS123 | 853 | Karoo sandstone-hosted tabular deposit |

| OREAS124 | 1794 | Karoo sandstone-hosted tabular deposit |

NICKEL

| CRM_ID | Ni_ppm | Cu_ppm | Comment |

| OREAS13b | 2247 | 2327 | PGE-Cu-Ni |

| OREAS182 | 7070 | 52 | Laterite |

| OREAS187 | 13700 | 40 | Laterite |

| OREAS72b | 7086 | 193 | Sulphide |

| OREAS73b | 15044 | 430 | Sulphide |

| OREAS74b | 33933 | 947 | Sulphide |

| OREAS75b | 53825 | 1483 | Sulphide |

| OREAS76b | 77800 | 2262 | Sulphide |

COPPER

| CRM_ID | Cu_% | Comment |

| OREAS901 | 0.141 | Low grade transitional oxide copper-gold |

| OREAS902 | 0.301 | Low grade transitional oxide copper |

| OREAS903 | 0.652 | Medium grade transitional oxide copper |

| OREAS904 | 0.612 | Medium grade transitional oxide copper |

| OREAS504b | 1.11 | Porphry Copper-Gold-Molybdenum |

| OREAS100a | 0.169 | IOCG – granitic and haematitic breccia |

| OREAS101b | 0.416 | IOCG – granitic and haematitic breccia |

| OREAS102a | 0.289 | IOCG – granitic and haematitic breccia |

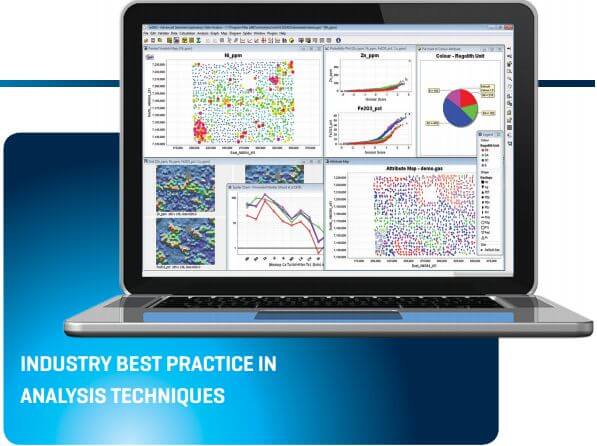

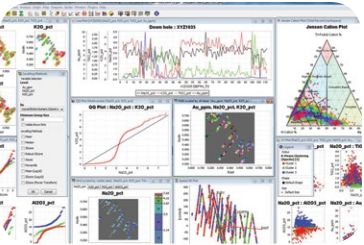

XRF DATA ANALYSIS SOFTWARE

Effortlessly detect patterns, anomalies and relationships in your geochemical and geometallurgical data.

Inbuilt knowledge

Knowledge from ioGAS experts is captured to deliver optimised workflows and easy-to-use tools that incorporate industry best practice in interpretive techniques.

Streamline data

Import data from a variety of source formats including Excel, Text, CSV, HUB, ODBC connection and selected field portable XRF units.

Real time data capture

Interact with data in real time using the ioGAS dynamic graphical environment to get to the right targets and facilitat timely decision making.

Trial ioGAS Software

TRIAL ioGAS SOFTWARE: Download a free two-week trial of ioGAS from our website. 32 and 64-bit Windows & Mac versions are available.

DATA ANALYSIS SOFTWARE

ADVANCED DATA HANDLING

- Streamlined data import (Excel, Text, CSV, HUB, ALS Webtrieve, ODBC connetion)

- Field portable XRF data import utility

- Data validation tools

- Automatic unit, oxide and molar conversions

- Missing data patterns

- Append new data

DYNAMIC GRAPHICAL ENVIRONMENT

- Univariate statistics, histograms, probability plots, box plots

- Scatter plots, 3D plots, ternary plots

- Multiple plot generation and vector file output

- Templates for preset lists of diagrams and plot windows

- Store and restore checkpoints

MULTIVARIATE STATISTICS

- Regression analysis

- Principal components analysis

- Mahalanobis distance analysis

- Cluster analysis

- Discriminant projection analysis

MAP AND SPATIAL VISUALISATION

- Subset sample point data using colour, shape and size attributes

- Gridded interpolation maps

- View spatial distribution for more than 20 elements instantaneously

- 3D XYZ plots and stacked line plots for drillhole visualisation

- Export to Google Earth, ArcGIS, MapInfo, 3D DXF

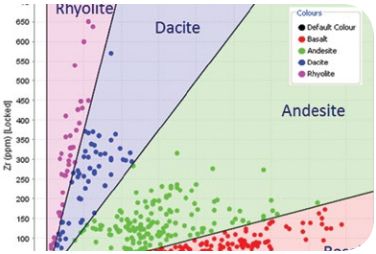

PETROLOGY

- Comprehensive rock classification diagrams

- Up-to-date alteration indices from international journals

- Display mineral and rock composition nodes

- Point density gridding

- Normalise data to selected geochemical compositions

ADVANCED APPLICATIONS

Our team of geochemists have developed unique and effective tools for quickly and accurately identifying mineral exploration targets based on the following geochemical analytical methods:

- Tukey outlier identification

- Data levelling and weighted sums

- Parallel coordinate plots

- Robust multivariate statistical analysis

MINING GEOMETALLURGY

Use ioGAS to measure geometallurgical parameters and incorporate them into resource models to better estimate plant throughput rates, processing costs, ore recovery and improve mine planning.

- Compile rock properties such as specific gravity, multi-element data or phase specific data (e.g. extractable copper, sulphide sulphur, silicate nickel, carbonate, organic carbon) from exploration or grade control samples

- Estimate mineral compositions, hardness, grindability, liberation and acid consumption parameters

- Map deleterious elements

- Model ore deposit geometallurgical domains

TRAINING

A range of training options is available including public, online and custom in-house training courses. Get up to speed with our ioGAS Fundamentals course or for the more experienced user, enhance your ioGAS knowledge with our Advanced Techniques course. See our website for course details and upcoming training dates.

XRF Geochemistry can also provide applied geochemistry training (including ioGAS) as part of an exploratory data analysis workflow tailored to client-specific needs. A combination of theory and case study examples from a range of topics such as pathfinder associations, primary and secondary dispersion, partial leaches, surface sampling strategies, QAQC, lithogeochemistry, geometallury and target identification can be undertaken and applied to your own datasets.

HOW TO USE A XRF GUN ANALYZER

Let me show you how quick and easy it is to use your Olympus Delta XRF Analyzer right out of the case, and how to be safe when using it.

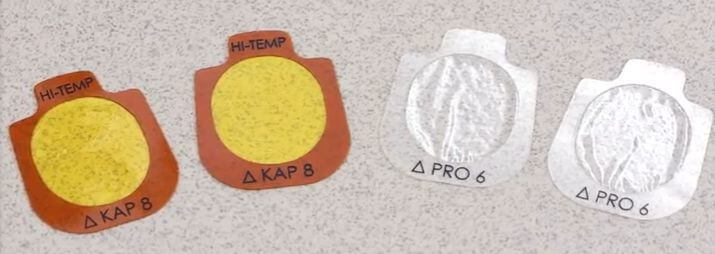

When you first open the case, you’ll find the shipping papers and documentation for your Delta, your Delta Analyzer, two lithium-ion batteries,

the Cal Check coupon, USB cables, a USB drive that includes software and user documentation, either Kapton or Prolene windows

and the AC adaptor for the docking station.

Underneath the first layer of protective foam you’ll find the docking station and the AC adaptor for the Analyzer if you bought one.

To use the Analyzer, pull open the battery latch and insert one of the fully-charged batteries, then close the latch. The batteries only go in one way.

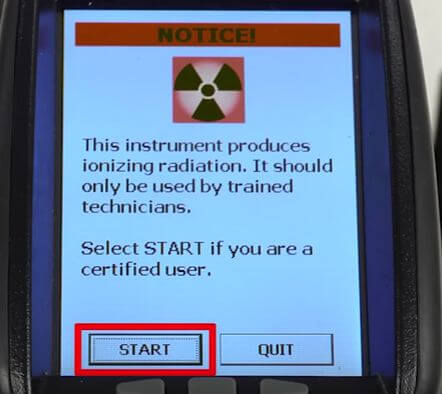

If the battery isn’t sliding into position, take it out, rotate it, and slide it back in. Press the power button on the top of the Analyzer. After it powers up, the radiation safety notice appears. After you read it, tap start.

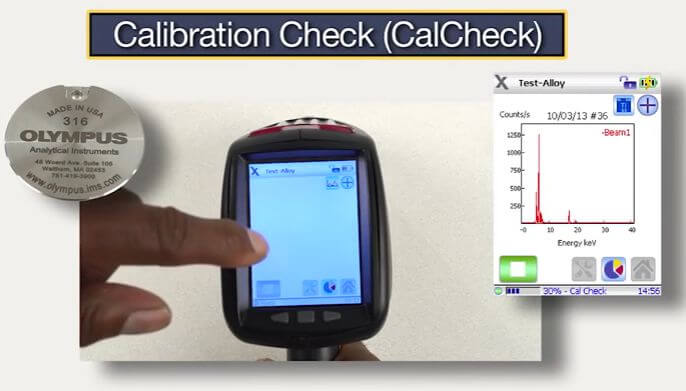

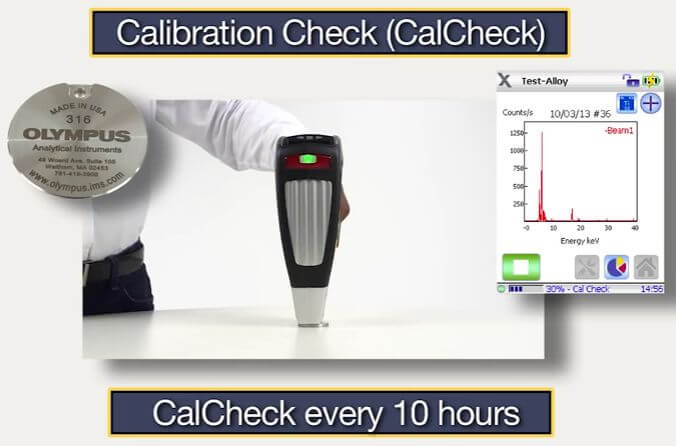

Because this is your first time using the Analyzer, it will need a calibration check. The Calibration Check or Cal Check makes sure that the Analyzer is working correctly.

The Analyzer will need a Cal Check approximately every 10 hours, whether it’s being used for those 10 hours or not.

Put the Cal Check coupon on a flat surface and place the Analyzer window on the coupon.

Tap the Cal Check icon on the Analyzer screen. Cal Check will take less than 30 seconds.

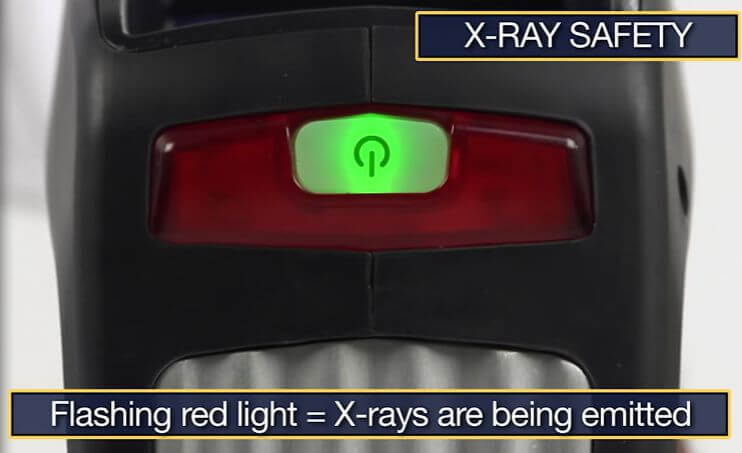

Cal Check is an X-ray test, so the red X-ray indicator will be flashing to warn you that X-rays are being emitted.

This is a good time to talk about X-ray safety. As long as you use your Delta Analyzer correctly, and follow the recommended testing techniques and safety precautions found in your manual, you and everyone around you will be safe.

Our instruments are secure and dependable, but there are a few things that are important for you to know. When the red light is flashing, X-rays are being emitted. Never point the Analyzer at yourself. Never point the Analyzer at anyone else.

Never place your hand in front of the Analyzer window.

Once Cal Check is done, your Analyzer is ready to use. Your Analyzer has been configured to your specifications. The Delta in this video has been configured for metal allow identification, so we are going to test some metal.

Deltas with an allow calibration will have the window guard system installed. For premium and professional models capable of testing lighter elements, you must remove the window guard window and change your mode to Alloy Plus to test for these elements.

Testing is a short, simple, 3-step process. Place, test, view the result. Your Delta is configured to end testing when an alloy has been identified, so you don’t have to determine when a test has ended. As soon as a test is over, you can go on to the next test. Remember, when the X-ray indicator is flashing, X-rays are being emitted. When the X-ray indicator is solid red, the X-ray tube inside the Analyzer is powered on, but not emitting X-rays. The battery in the Analyzer should last for about 4 hours.

All Deltas have hot-swappable batteries, so you don’t have to power down the Analyzer just to put in a fresh battery.

To swap batteries, just open the battery latch, pull out the battery and insert a fresh one. A countdown screen shows you how much time you have to complete the swap. Once the fresh battery is in, you can keep right on testing.

When you are using the Delta for any length of time, place it in the docking station. The docking station will automatically run a Cal Check, automatically charge the battery in the Analyzer and automatically charge the backup battery.

As long as the Analyzer is powered on, the docking station will recognize it. The status of both batteries will be displayed on the Analyzer screen and a Cal Check will be performed automatically.

CONFIGURING AND EXPORTING THIS XRF GUN

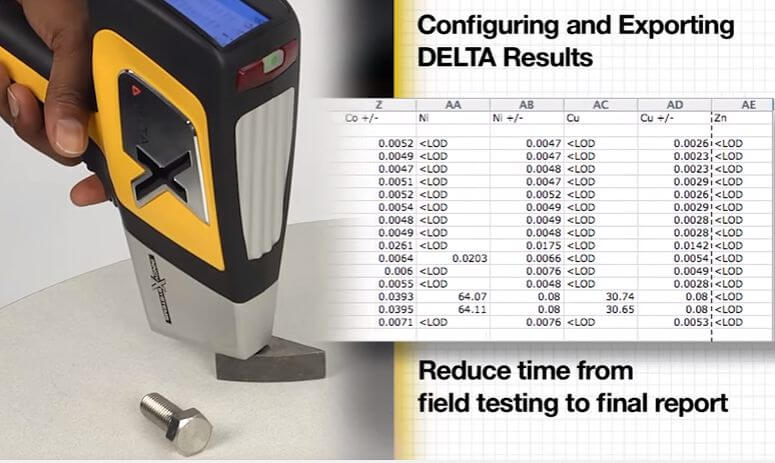

Just to show you how easy it is to export test results from the Olympus Delta hand-held XRF Analyzer and how to reduce the time required to go from field testing to the final report.

The results report generated by the Delta, whether in digital or hardcopy form is often the most important outcome of field testing.

The ability to customize the Delta’s export format to meet the needs of your project, application or company’s preferred data format is a powerful time-saving feature.

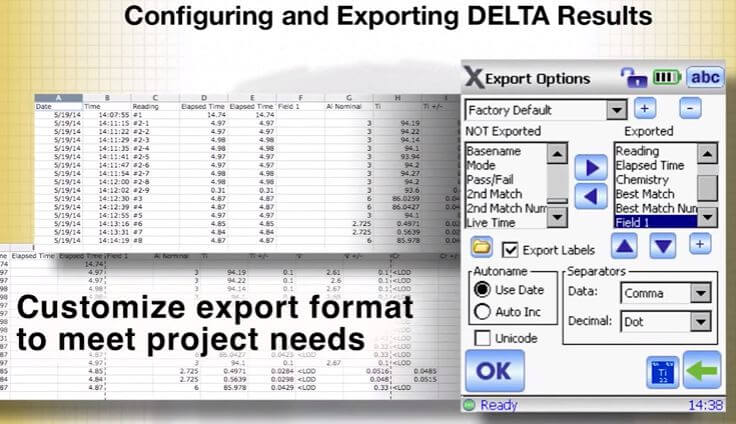

The Delta has simple, intuitive tools for customizing the order of columns, positioning the test labeling and displaying the information needed.

If your organization requires more than one reporting format, you can easily save templates for later use.

You can then seamlessly merge the Delta export results with a Word or Excel document to create a client-specific summary.

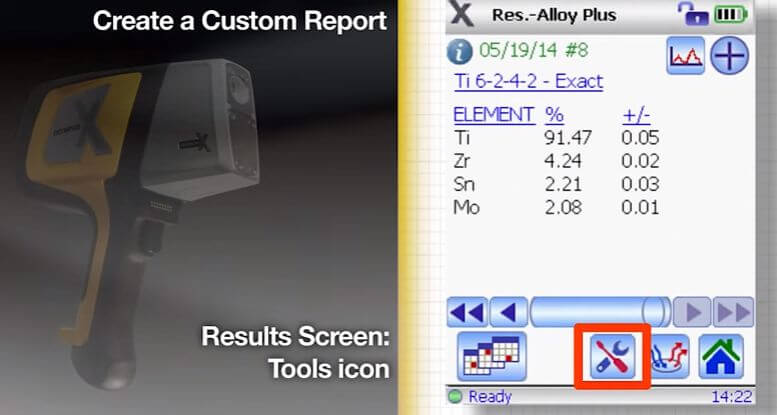

The following example shows you how to create a custom report. On the Results screen, tap the Tool icon at the bottom of the screen.

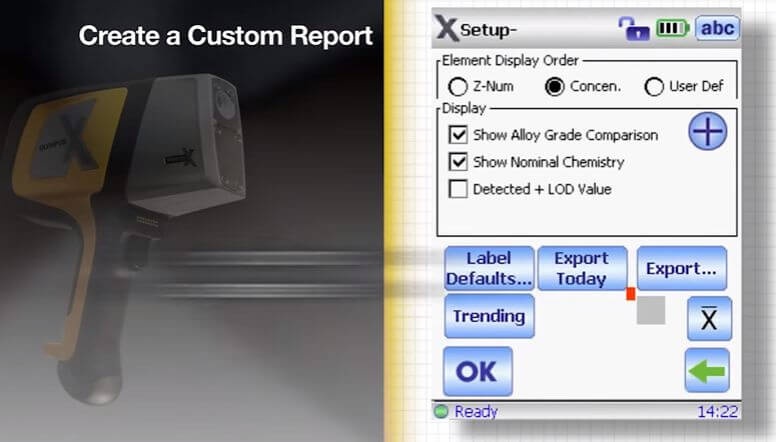

The Export Today button is a convenient shortcut to output today’s test results. Tap the Export button to customize.

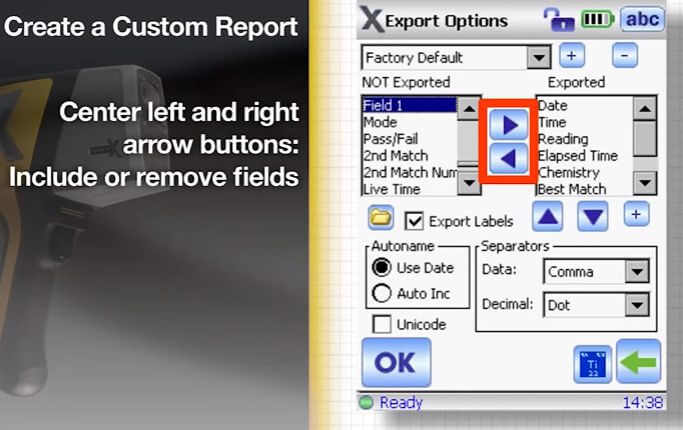

Here’s where you can select what data you want to export. Select the tools icon again. Use the center left and right arrow buttons to include or remove fields from the report.

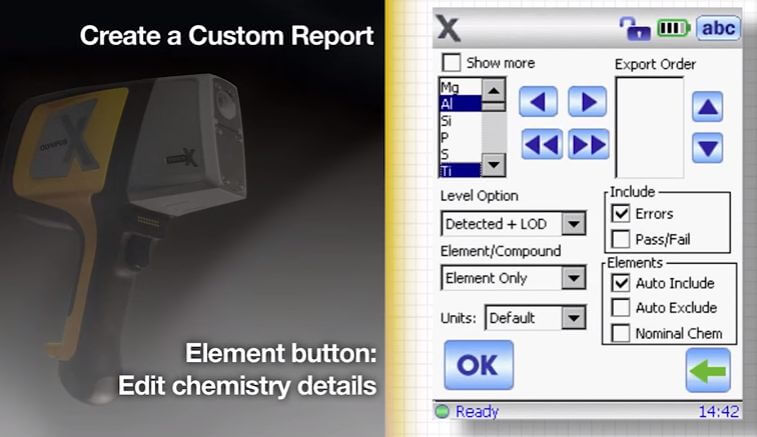

Use the up and down arrow buttons to change the order of columns displayed. You can tap the plus button to make a custom column of your own; it will be added to your list of exported columns. Press the Element button to add in the details of the chemistry section.

Elements can be added or removed from the report just like other columns. To change the location of the saved file, select the export destination by tapping the folder icon. Now that we have changed some settings, we can save this as a template.

![]()

Tap the plus icon at the top of the Export Options page and then select Yes to save and name your template.

Now it’s time to export the data. Tap the export icon in the lower left-hand corner. The test results are stored in a tamper resistant encrypted database on the Delta.

![]()

The data is exported in a .csv format containing comma-separated values which is easily read by a spreadsheet program like Microsoft Excel. You can save multiple export formats to review test results. To review, the key export features are: selection of columns, customizing the order of columns and displaying the information needed.

Through simple, intuitive customization you can make your export results match your final report format. Save the template to support multiple field inspectors, client requirements and testing applications.

Exporting report results from the Delta handheld XRF Analyzer is fast and easy. You’ll save time and money by shortening the distance from field measurement to the final report.

Olympus DELTA Element

The newest and most affordable addition to the DELTA family of handheld XRF analyzers.

The DELTA Element offers powerful analytical performance for fast, accurate results in a cost-effective handheld XRF analyzer. The Element offers fast measurement, low limits of detection and outstanding precision. The DELTA Element’s compact, accurate and fast testing is completely non-destructive as it uses X-ray fluorescence to evaluate material chemistry in seconds.

With fast elemental ID for screening, sorting and metals analysis, the Element provides a quick return on investment for scrap, PMI, QA/QC and precious metals applications. The Element’s field worthy and rugged design features rubber overmolds and a thick Kapton measurement window to protect the analyzer in tough processing environments.

The rechargeable lithium-ion batteries can be hot-swapped or changed without powering down the analyzer. The DELTA Element has all the advanced features of the DELTA family, including grade match messaging, nominal chemistry and a tramp library to make operators more efficient for greater throughput and quick ROI.

For scrap recycling environments, the Element provides fast, reliable ID in seconds. Designed to withstand the toughest processing environments, the Element enables sorting and analysis for high-alloy steels, such as stainless steel and titanium. When reliable material analysis is required, the DELTA Element provides fast and accurate positive material identification. The Element allows testing anytime, anywhere.

For alloy QA/QC applications, the Element rapidly and accurately identifies alloy grades and pure metals for quality control and assurance. The element determines alloy chemistry grade ID to confirm material specification from the manufacturer to the end user. The element comes equipped with both alloy and precious metals calibrations, for identifying accurate karat classification at no extra cost. Test results can be viewed on screen, and the analyzer has a USB port for downloading results and seamless PC control.