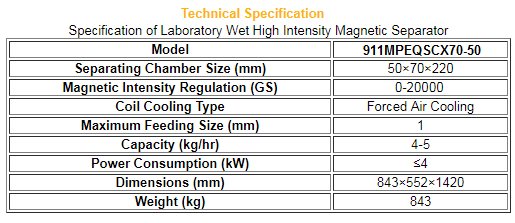

TUNGSTEN & HIGH-INTENSITY WET MAGNETIC SEPARATOR

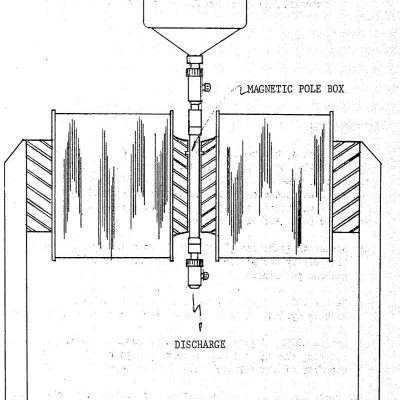

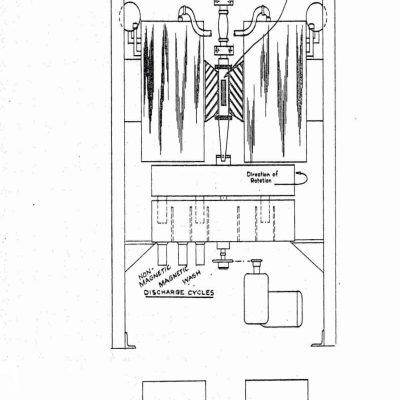

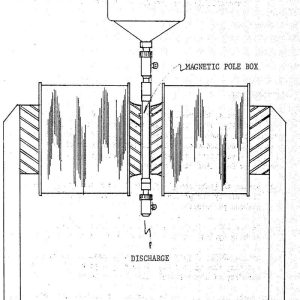

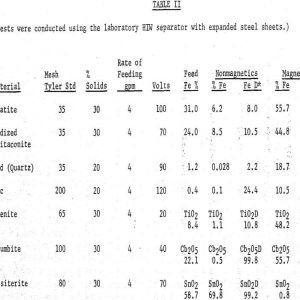

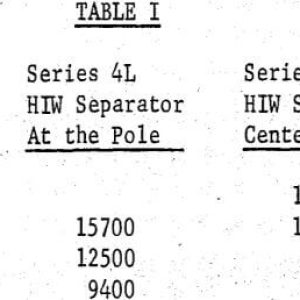

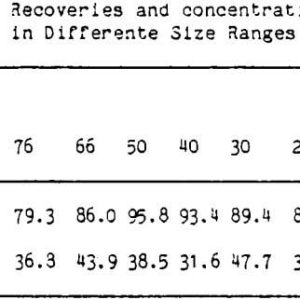

Wolframite minerals, being weakly magnetic with a specific susceptibility of 39×10 -6 to 46×10 -6 cm³/g, can be effective separated from cassiterite and other nonmagnetic minerals and gangue using a high-intensity wet magnetic separator (HIWMS). Recently, various versions of this machine made in China have been introduced in wolframite mines. For example, by using the SQC series HIWMS machine to treat the wolframite slime at a plant, a concentrate grade of 8.4% WO3 (concentration ratio of 19.2) with a recovery of 75.96% was obtained. The lower limit of effective recoverable size was found to be 10 µm (corresponding to wolframite size 5.3 µm) under a condition of maximum field intensity of 1.8×10 4 Os in the separation zone (Table 3). for cleaning and upgrading, various types of HIWMS are being employed to separate wolframite from cassiterite, apatite, scheelite, etc. for example, in another plant, using the SQC-Z-1100 type HIWMS and a rougher concentrate containing 44.72% WO3 and 1.3% Sn, a final product grade of 55.66% WO3, with 0.19% Sn was obtained at a recovery of 95.47%.

In addition, a new type of high-gradient magnetic separator (HGMS) has been used in tungsten ore processing. Treating a refractory slide which contains 27.55% WO3 53% Sn, and 74% minus 74-µm fraction, the machine gave a final concentrate grade of 63.98% WO3 and 0.4% Sn with a recovery of 82.65% WO3.