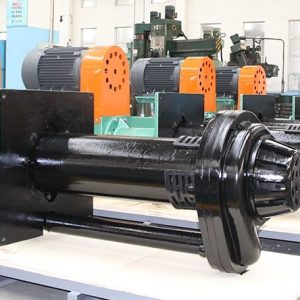

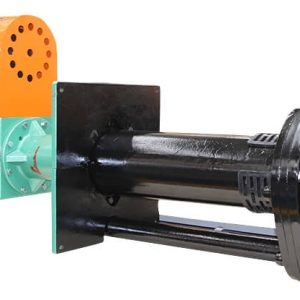

SP/SPR vertical sump pump is of vertical cantilevered design with hard alloy wear parts or full rubber covering option which can run continuously in abrasive and corrosive pumping environment. Vertical slurry pumps not only provide excellent wear life properties, they also operate efficiently to further reduce operating costs. There are no submerged bearings or packing with a unique high-capacity double suction design. Optional recessed impeller and suction agitator are available. SP/SPR heavy duty sump pumps are available in various standard lengths to suit different sump lengths.

Bearing Assembly

The vertical cantilever design with no gland or submerged bearings avoids the need for expensive gland or bearing flushing water.

Back Liner

The opened back liner allows plenty of room for the oversized shaft with slurry to pass through and pump from the top and bottom. The top suction draws the slurry away from the drive end.

Casing

Casings are made of cast high chrome alloy steel with rubber or metal lined option

Impeller

- Double suction impellers create low axial bearing loads, increasing bearing life

- Impellers are available in rubber-lined and metal-lined option

Lower Strainer

The lower strainers keep large foreign material entering the casing

Application

The rugged SP/SPR vertical sump pump with either hard metal or rubber covering are suitable for the following applications:

- Minerals processing;

- Coal preparation;

- Industrial sand and Aggregate;

- Power Plants;

- Chemical processing;

- Effluent handling;

Features & Benefits

- Cantilever design without submerged bearings or shaft seal;

- High capacity double suction design;

- Agitator option keeps solids in suspension;

- Wear parts are available in variety of different material;

- Optional recessed impeller for oversized material;

- Open and semi-open impeller available

- SPR models features full rubber covering for corrosion resistance