With the rising price of gold and the limited amount of mineable land, people are now focusing on the recovery of fine gold. Some rivers of the world have been sluiced as many as 6 times, yielding profitable gold each time – and demonstrating that traditional sluices can have very poor recovery.

“Small” Gold Wash Plants like the IGR500 focuses on the recovery of Fine Gold.

The submersible feed pump can be placed in the belly pan of a trommel/screen deck, placed directly in the tails of a sluice or used as a booster pump for dredge operations.

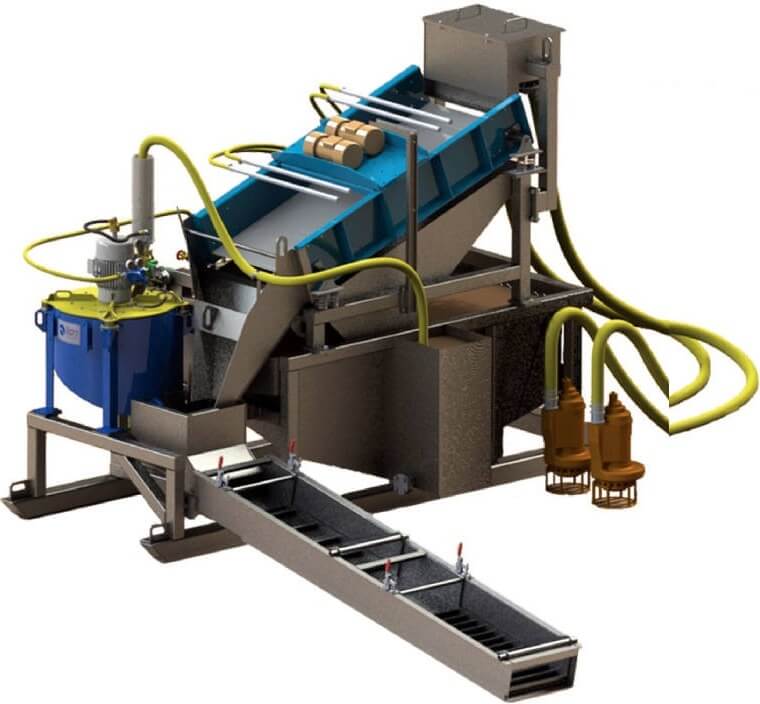

The IGR 500 is a Modular Pump Fed Plant.

- The pre-screened gravel is transported to the plant by 2 5 HP, 3-inch submersible slurry pumps.

The feed pumps are the same model as the transport pump for the commonality of parts. - The maximum solids capacity of the pump is 7/8 inch, 1/2 inch recommended

-Screened by a sluice plant, trommel, vibrating screen, grizzly or suction dredge - The slurry is distributed over the single-deck vibrating screen

-The -2mm material is pumped to the i350 Concentrator

-The +2mm material is passed to the high-efficiency sluice - A specially designed hopper acts to dewater/thicken the slurry while paying close attention to retaining the fine and/or floating gold

- A third 5 HP, 3-inch submersible pump transports the -2mm slurry to the concentrator.

The plant includes 3 x 5HP submersible pumps: Model KZN37.