DESCRIPTION

This machine has lightweight aluminium lift doors on both sides for unrestricted access to grinding barrels and automatic air clamp and electronic timer for adjustable grinding cycles.

You can operate this machine with 1 x 4kg grinding barrel, 4 x 250mL grinding barrels or 2 x 1kg grinding barrels and an air hoist for removing or inserting 4kg barrel is optional and can be mounted on either side.

The rugged stainless steel cabinet has sound dampening enclosure and the heavy duty long lasting motor has been proven by years of service.

It weighs 375kg and comes in 3 phase/60 cycle, 1.5Hp motor as standard. 1 phase and / or 50 cycle motor available. These options need to be specified at time of ordering. All grinding barrels are sold separately.

We like to inform you of the composition of the different steels and other materials used in the manufacturing of grinding barrels to help you choose the most suitable ones for your operations.

Attention User

This manual might have illustrations, parts, and instructions that may not pertain to your machine.

Warning

The vibrating body of the machine has been secured rigidly to prevent damage during shipping using four ½” screws on top of the vibrating body and four under the springs’ plate. REMOVE THESE HOLDING DEVICES BEFORE ATTEMPTING TO OPERATE THIS MACHINE. ADD BALLAST BEFORE STARTING THE MACHINE.

(Read further instructions)

One Year Limited Warranty

This Pulverizer is warranted against defective materials or workmanship for one year from date of original purchase. This warranty is void if the product has been damaged by accident, unreasonable use, neglect, improper service, by not following the instructions in this owner’s manual, or other causes not arising out of defect in material or workmanship.

Attention Purchaser

Any Alterations, Re-Wiring or Modifications To Be Done On This Machine While Under Warranty, Must Be Authorized By The Manufacturer Otherwise All Warranties Become Void.

4KG Troubleshooting Procedure When Machine Won’t Start

First check :

- to ensure the air pressure is 90-94 psi

- to ensure the pressure gauge is functioning properly

- if the PLC display operates this confirms there is power going to the machine

- to ensure the electric motor is mechanically functional (full rotation)

- to confirm the door is closed and also the electrical interlock to allow the machine to start

Instruction Manual for Vibratory Ring Pulverizer Model TM/4KG

- Description

- Installation

- Electrical Connections

- Maintenance

- Operating Instructions

This manual is the only instruction needed for keeping and maintaining the V.R.P. in operating conditions. Read it carefully before operating the Pulverizer.

It is T.M. Engineering’s Policy not to supply manufacturing drawings, production, and technical information that don’t pertain to the operation and use of the machine. If any additional information is required to operate or repair this machine, please contact our service department.

We decline all responsibilities if mishaps occur due to unqualified person wiring and manipulating the electrical system of this machine.

Description

This Vibratory Ring Pulverizer consists of:

- Sound dampening enclosure with hinged door.

- Vibratory body with a clamping system.

- Electric motor

- Control panel

- Grinding Barrel(s)

- Air Hoist (for machines supplied with one)

The grinding barrel(s) are mounted and locked on the vibratory body with the airbag self-adjusting clamping device. The hinged door should be closed during operation.

The control panel has a green start button (V061), an emergency red stop button (V062E), and a PLC (V063A). See Figure 6. To start the grinding cycle, one can either use the soft key ‘DEL’ on the PLC touchpad or alternatively the green start button. Should one want to stop a grinding cycle before the expiration of the pre-set time, the soft key ‘ALT’ on the PLC should be pressed. The emergency red stop button should be used only in emergency situations as it cuts out all functions including air pressure. In normal circumstances, the machine will retain air pressure for a short while after completing the grinding cycle to allow the mechanical components to reach a stand-still position.

The pulverizer should be used at all times in accordance with the instructions.

Installation

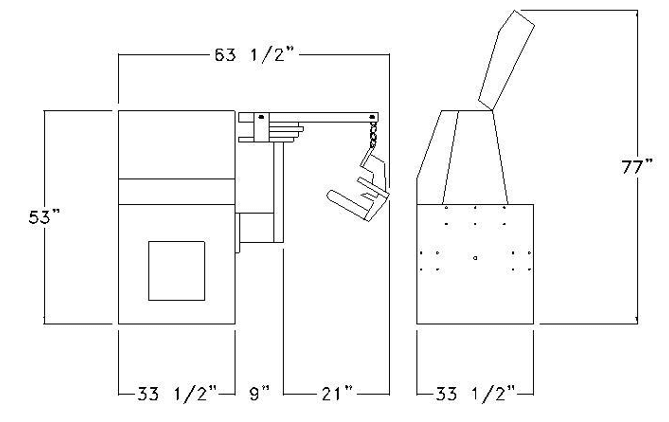

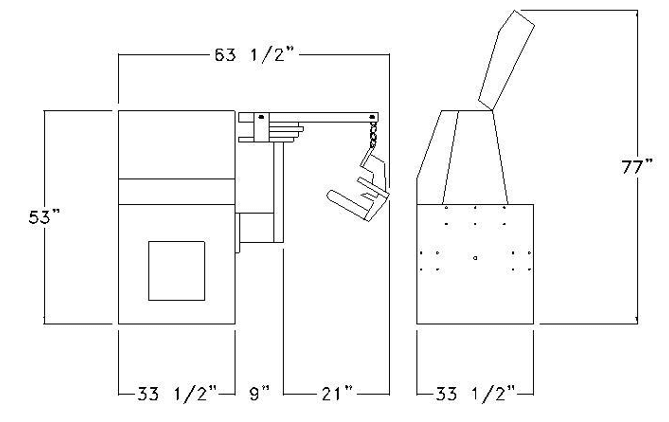

The pulverizer must be installed on a flat horizontal surface. Since the pulverizer is shipped without ballast in the base, no less than 450 lbs./200 kgs of ballast must be added in the form of lead slabs, grinding balls, scrap steel, rocks or similar material. DO NOT bolt the pulverizer on the floor. If the weight does not stop the machine from walking, bolt down angle irons or pieces of wood as per the attached drawing to prevent it from moving. Please note: the two front feet have adjustable bolts to allow leveling on uneven floors. Refer to Figure 1 for an illustration of how to install the pulverizer.

DO NOT OPERATE the pulverizer without ballast in the base to avoid severe rocking. This could happen, especially during the start-up and slowing down of the machine, at the end of each grinding cycle.

During transportation, the vibratory body is secured with steel bolts and pipes at the base and the vibrating body. YOU MUST remove these items before operating the pulverizer.

The clamping system air regulator V084G, (See figure 6) should be set to exceed 620 kilo pascals (90 psi) and no more than 648 kilo pascals (94 psi). The clamping system pressure switch is preset at 620 kilo pascals (90 psi).

Should the pressure switch need to be re-calibrated, the silver screw on it V082G (See Figure 6) is the one that activates the grinder motor once the 90-94 psi pressure has been achieved. The pressure switch is located inside the control panel and it is connected to the air valve via a brass tee. To increase pressure, turn it clockwise.

Also in the control panel there is a vacuum valve (V070E), which controls the airbag retraction. See Figure 6. With the air supply on, an air flow of 7-8 psi can be heard from the valve exiting it even between grinding cycles. At this pressure, the airbag will fully retract in 4-6 seconds. If the machine is not being used for a long period of time, turn the main air line supply off (V070B Ball Valve).

Pulverizers supplied with air hoist

The air hoist can be installed on either side of the machine. The air hoist regulator is factory preset for gentle lifting of the Grinding Barrel containing the grinding element and grinding media.

Should more lifting force be needed, pull out the pressure regulator knob and turn it clockwise the needed amount, then push it back. Likewise, turn it counter-clockwise if too violent raising force is generated when the grinding barrel is lifted with an air hoist. The hoist arm has a screw at the rear end to adjust maximum lifting height should one want to pre-set it.

Electrical Connections

A wiring diagram of the electrical system of this pulverizer is attached. Refer to Figure 2.

The electric motor is usually wired according to the customer’s power supply. Also, a tag is attached indicating the voltage required.

Check the power available on the site to ensure that the pulverizer is connected to the correct voltage.

Changes in wiring must be made by a qualified electrician. HAVE THE ROTATION OF THE PULVERIZER MOTOR ACCORDING TO THE ARROW SHOWN ON THE MOTOR FAN COVER. The elliptical motion of the machine while in operation will tell you the motor rotation.

Maintenance

The motor bearings are factory lubricated. They need to be greased every 30 hours. One to two squirts of grease each nipple is sufficient. The PLC will display the word ‘GREASE’ when this operation is due. You need to press ESC and DEL simultaneously to reset the PLC and then continue your grinding process. If any need of maintenance/repair of motor, vibrating body, bridge, etc. arises, do the following: disconnect the motor cable from the panel and air line from the air bag, then remove the top portion of the cabinet (which includes the door). Attach two hooks or straps and carefully remove the vibrating body from the cabinet. Refer to Figure 3 for an illustration for removing the vibrating body.

Undo the Screws holding the motor to the vibrating body. Do the same for the motor flanges. If necessary, pry out the motor and motor flanges by screwing in the removed screws in the threaded holes at the flange’s periphery. The bearings have internal seals mounted in the steel housing removable after undoing two screws. Proceed with this operation and then it will be possible to remove bearings, inspect, clean, or replace, re-grease, and re-assemble.

Instructions For Installing Bearing On Electric Motor Shaft And Main Flange

Pack bearing with grease (Unirex N2L or Lubriplate 1200-2, or a similar grease). DO NOT overfill – the bearing should have half-empty space when greased. Install it into main flange and mount cover plate. Repeat this procedure with the bottom end bell.

Place main flange upside down and press in the rotor shaft until bearing’s face butts against shoulder on motor’s shaft. Mount stator to main flange and then bottom end bell.

Instructions For Correctly Installing Eccentric On Motor Shaft

- Place on the ground a ring or a couple of pieces of wood big enough and thick enough that the projection on the end bell on the bottom of the motor clears the ground.

- Set the eccentric on top of the motor shaft and lead the eccentric onto the shaft with the keyway in line with the key on the motor shaft. Hammer down on the eccentric making sure to give blows evenly around the eccentric bore. Tighten the spacer washer and screw to hold the eccentric onto the shaft.

- At this point, place the vibrating body back onto the motor making sure that the motor electrical box is in position as to locate the motor wire through the frame in the proper direction. Re-tighten the screws to secure the motor to the vibrating body.

Failure to Follow this Procedure Might Cause Immediate Wear and Break Down of the Entire Motor

Attention Maintenance Person:

Bars mounted on the bowl’s locating disk, adaptors, and vibrating body are to prevent grinding barrels from rotating; they can be welded in the wear areas and re-ground as original and used again.

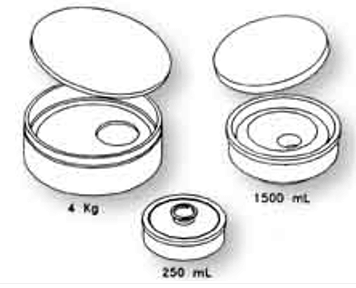

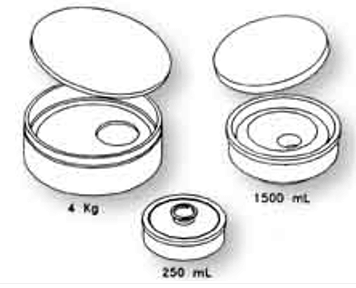

Operating Instructions

The 1kg, 2kg, and 4kg grinding barrels contain only one grinding saucer (disk). The 500mL grinding contains two grinding elements. The 250mL capacity grinding barrel contains three grinding elements: the solid center cylinder and two concentric rings. The 100mL capacity grinding barrel contains two grinding elements: the solid center cylinder and one ring. The material to be pulverized is poured between the rings in the 250mL grinding barrel and on top of the saucer/disk in the 1kg, 2kg, and 4kg grinding barrels.

The grinding barrel is placed on its seat. Then the hinged door is closed over the moving part of the Pulverizer. The grinding time required to pulverize a certain mass of materials is set on the PLC prior to commencing the cycle. Pushing the touchpad start button will activate the air actuator which will lock the grinding barrel in its seat and then the motor will start (see Figure 7 for how to operate timer).

The red push button is the emergency switch (V062E). When you press it, the motor will stop and the air pressure will be released.

Open the cover and remove the grinding barrel. Usually the lid can be removed easily. However, if the lid is stuck to the barrel, a brass hammer or similar tool should be used to gently tap the underside of the protruding rim of the lid.

Brush of powder stuck to the grinding elements. Remove one element after the other while cleaning making sure that samples’ powder won’t be dispersed in the process.

Empty the contents of the barrel onto a TM stainless steel mixing tray, on glossy paper, on a sheet of rubber or similar material. Homogenize the sample by coning with two mixing trays, sub-sample by incremental division scoops for this procedure.

Grinding times depend on a number of factors:

- mass of material

- hardness

- particle size

- lubricating properties

Since the capacity of the grinding barrel is rated in mL rather than in grams, the mass of a sample will depend on its bulk density.

The volume of a sample may range from 100 mL up to 250 mL with 250 mL being the optimum capacity; for the 100 mL capacity grinding barrel the volume of the sample will be proportionally less, just as it will be proportionally more for the 1 KG, 2 KG or 4KG grinding barrel.

For soft materials such as coal, dolomite, etc. the maximum particle size of the feed can be as large as 15 mm. For hard materials such as pre-reduced iron ore, ferroalloys, etc. the top particle size should not exceed 5 mm.

Some soft materials such as talcum tend to lubricate the grinding elements. Others may form conglomerates of particles on the periphery of the barrel (caking) in a short time.

Pulverize such materials in increments of 0.1 minute and check the fineness after each interval. If the required fineness cannot be obtained without caking, add 2 – 5 mL of ethanol freon solvent and pulverize for a time period that caused caking in dry condition plus 0.5 minutes.

Samples containing excessive amounts of moisture may also cake and should be dried before grinding.

Air Clamp

The machine control is set to retain air pressure in the clamping air bag for 8 seconds after termination of grinding cycle. This is necessary for safety reasons.

Instructions for Electrical Trouble Shooting

Before Servicing – Disconnect Electrical Power

All components are at line voltage. Should the control panel fail to function, we recommend that a local qualified electrician be called. We invite you to have the electrician contact us should he have any problems in trouble-shooting or obtaining parts to rectify the failure.

Important Note:

If installing a new replacement motor, make sure that the inside of the chamber underneath the vibrating body where the eccentric attached to the motor is mounted is extremely CLEAN. This is imperative to prevent bearing failure as it is exposed to the chamber’s impurities.

Description Of Parts For a 4kg Vibratory Ring Pulverizer

Quantity in brackets refers to how many pieces required per machine. Please specify voltage and serial number of machine when ordering

V001………………………..Pulverizer Feet for Cabinet (4 pcs.)

V002………………………Screws to retain Front Door (4 pcs.)

V003Z…………………………….Cabinet Front Door

V004GZ…………………………..Pulverizer Cabinet

V005Z-2……………………….Plate for Vibrating Body

V005A4KG……………………Vibrating Body Springs (6 pcs.)

V005BZ-1…………………………Spring holder top side (6pcs)

V005BZ-2…………………..Spring holder bottom side (6pcs)

V005CZ……………….Nylock Nut for Spring Guide (12 pcs.)

F005FZ………………………………Rubber for stabilizer (3pcs)

V005GZ-2………………………………..Stabilizer holder (6pcs)

V005HZ-1……………………………………………….Screw (4pcs)

V005JZ-1…………………………….Countersunk screw (3pcs)

V005KZ-1……………………………………Bottom screw (3pcs)

V005LZ-1……………………………………………….Screw (2pcs)

V006……………………..Nut, bolt and lockwasher for Retaining Plate of Vibrating Body (12 sets)

V007K……………………………………..Interlock safety switch

V014GV……………………………………………………Top Door

V017AZ………………………………………………………Handle

V017D…………………………………………………….Screws (11 pcs.)

V017E………………………………………………………Door Support

V018AY…………………………………………………..Terminal Block

V018Y…………………………………………..Electrical Box & Cover for Motor

V019AKZ-1……………………………….208/220/380/440 volt Motor, 3 phase

V019BKZ-1……………………………………………..575 volt Motor, 3 phase

V020Z…………………………………………….Screws to mount Motor to VB (6 pcs.)

V021Z………………………………………………………..Lock Washers for Bolt (6 pcs.)

V022Z………………………………………………………………….Motor Key

V022CZ………………………………………………………..Motor Bearing (2 pcs.)

V022DZ……………………………………………………………..Inner Seal (2 pcs.)

V022EZ………………………………………………………………Seal Holder

V022FZ………………………………………………Screws to hold Seal Holder (2 pcs.)

V022GZ……………………………………………………………..Outer Seal (2 pcs.)

V022HY……………………………………………………………..Fan Guard

V022HY-2………………………………Block and screws to fasten Fan Cover (4 sets)

V022JZ……………………………………………………………..Motor Fan

V022LZ…………………………………………………………….Fan Washer

V022JZ…………………………………………………………….Motor Fan

V022MZ……………………………………………………….Fan Lockwasher

V022NZ……………………………………………………………..Fan Screw

V022PZ……………………………………………………….Motor Bottom Flange

V022RZ-1……………………………………………………….Motor Top Flange

V022RZ-2…………………………………………………..Motor Top Flange Insert

V022TZ………………………………………………………Motor Top Flange Cover

V022UZ………………………………………..Screws for Motor Top Flange Cover (6 pcs.)

V022VZ………………………………………………………………Check Valve

V023ZX-4……………………………………………………………..Eccentric

V026V-3……………………………………………………………Vibrating Body

V026ZG-1 4KG……………………………………………………Locating disk

V028-2………………………………………………..Dowel Pins for Locating Disk (4 pcs.)

V028-3…………………………………………………Countersunk allen screws for 4kg locating disk (12 pcs)

V034A……………………………………………………Dowel Pins to locate Bridge to Vibrating Body (6 pcs)

V039B……………………………………………………Flexible Connector (motor) (2 pcs.)

V039E…………………………………………………….Base Plate for Wiring Box &Hardware

V070R…………………………………………………………….Bulkhead Coupling

V073………………………………………………………………Electrical Cord Connector

V159………………………………………………………………..Copper Grease Line

V160……………………………………………………………….Straight Brass Fitting

V161…………………………………………………………………………..90deg Fitting

V162…………………………………………………………………….Straight Fitting (3 pcs)

V163………………………………………………………………….Vibrating Body Bearing

V164…………………………………………………………………..Vibrating Body Seal

V165……………………………………………………………….Vibrating Body Flange Cover

V166………………………………………………………………………………Screws (6 pcs)

V167………………………………………………………………………Grease Nipples (2 pcs)

V168………………………………………………………………………………Screws (2 pcs)

V169………………………………………………………………….Aluminum Mounting Block

V171…………………………………………………………………………………Grease Gun

V172……………………………………………………………………………….Brass Fitting

V-HANDLE…………………………………………………Hook for 1kg, 2kg, & 4kg disk removal

4KG Clamp Assembly Parts

V030S……………………………………………….Air Bag

V033…………………………………………..Air Clamp Hose

V033A………………………………………Rubber grommet

V037U-3………………………………………Clamping disk

V037Z-1……………………………..Clamping disk screws (2pcs)

V070X……………………………………………¼” Male Fitting

V130-1……………………………..Angle Plate for Bridge (2 pcs.)

V131…………………………………………Bridge Bottom Plate

V132………………………………………..Bridge Frame (2 pcs.)

V133…………………………………Bolt for Bridge Frame (4 pcs.)

V134………………………………..Bolt for Bridge Frame (10 pcs.)

V135………………………………..Spacer for Bridge Frame (4 pcs.)

V136…………………………………………Lockwasher (20 pcs total)

V137………………………………………………….Nut (18 pcs.)

V141…………………………………………….Top Plate for Bridge

V142………………………………..Spacer for Bridge Frame (4 pcs.)

V143……………………………………………………Nut (4 pcs.)

V144……………………………………………..Lockwasher for V143

V145…………………………………………………Bridge Block (2 pcs.)

V146…………………………………………….Screws for V148 (8 pcs.)

V147……………………………………….Lockwasher for V146 (8 pcs.)

V148-1……………………………………………..Round Bar (2 pcs.)

V149…………………………………………….Washers & Nut (4 pcs.)

V150…………………………………………….Mounting Plate (4 pcs.)

V151…………………………………………………Re-enforcing tubing

V152………………………………………………………Screw (2 pcs.)

V153………………………………………….Screw & Hardware (2 pcs.)

V155-1…………………………………………………Stabilizer plate

V156-1………………………………………Stabilizer plate screw (2 pcs)

V157-3………………………………………………….Stabilizer bar

V158-3……………………………UHMW Ends and hardware (2 pcs)

V173…………………………….Screw Hold Air Bag to Clamp (2 pcs.)

V174-1…………………………………………..Clamps and hardware

4KG Control Panel Parts

Need to specify what voltage machine is wired at when ordering

V061……………………………….PUSH BUTTON START SWITCH

V062E…………………………….EMERGENCY STOP BUTTON

V063A-1………………………….PLC CONTROLLER

V067……………………………….MAGNETIC CONTACTOR BLOCK

V068……………………………….OVERLOAD

V069……………………………….TRANSFORMER

V070B……………………………..BALL VALVE

V070E……………………………..VACUUM VALVE

V070G……………………………..AIR SOLENOID VALVE

V070J………………………………PIPE PLUG

V070K……………………………..RUBBER GASKET

V070N…………………………….90 DEGREE FITTING (2 PCS)

V070R……………………………..BULKHEAD COUPLING

V070S………………………………DIN RAIL

V070U……………………………..REDUCER NIPPLE

V070X………………………………¼” MALE FITTING (4 PCS)

V070Y……………………………….MANIFOLD

V070Z……………………………….1/8″ MALE FITTING

V071B………………………………..TERMINAL BOLT

V071C………………………………..TERMINAL BLOCK

V071E………………………………..TERMINAL BLOCK

V071E-1………………………………RAIL STOP

V071D…………………………………TERMINAL BLOCK

V071H…………………………………FUSE HOLDER

V071K………………………………….FUSE

V071R………………………………….PANEL BOX & COVER

V071T……………………………….¼ TUBE TEE (QUICK DISCONNECT)

V073…………………………………..ELECTRICAL CORD CONNECTOR

V073A…………………………………ELECTRICAL CORD CONNECTOR

V073B………………………………….WIRE CONNECTOR

V076…………………………………….SCREW/BRACKET TO HOLD WIRES (2 PCS)

V077……………………………………..SCREWS FOR TRANSFORMER

V077G………………………………….CHECK VALVE

V082G………………………………….PRESSURE SWITCH

V084G………………………………….REGULATOR (2 PCS)

V085G…………………………………..GAUGE

V088G………………………………….HEX NIPPLE (2 PCS)

V090G………………………………….EXTRUDED STREET TEE

4KG Air Hoist Parts

V030…………………………………..Air Bag for Air Hoist

V039G………………………….Bolt & Washers to mount hoist (4 pcs.)

V070X……………………………………¼” Male Fitting

V070Q………………………………Air Line Steel Pipe Joint

V084G…………………………………………Regulator

V092G………………………………..Barbed Coupler Pipe

V093G………………………………..Barbed Coupler Pipe

V095G………………………………..Barbed Coupler Pipe

V095GX…………………………………..Post Stabilizer

V097G……………………………….Barbed Coupler Pipe

V098G……………………………….Barbed Coupler Pipe

V099G…………………………………………..Clamp A

V100G…………………………………………..Clamp B

V101G…………………………….Air Line for Air Hoist

V103G…………………………………..Braided Air Line

V104G…………………………………..Braided Air Line

V105G……………………………………………..Gasket

V106GX……………………………….90 Degree Fitting

V107G-1……………………………..3-Way Air Coupler

V108G………………………….Manual Air Valves (2 pcs.)

V109G………………………..Air Hoist Support (Assembly)

V110G………………………………………….Air Hoist Arm

V111G……………………………Yoke & Hardware (Assembly)

V112G……………………………………………….Chain

V113G……………………………….Bolt, Nut, & Lock Washer

V114G-1…………………………………….Lifting Basket Arm

V114G-2…………………………………….Detachable Basket

V114G-3………………………………………..Locking Pin

V114H-2……………………………………Detachable basket

V115G…………………………..Regulator Bracket & Hardware

V116G…………………………………Air Line Bracket & Screw

V117G………………………….Holders for Air Line & Hardware (2 pcs.)

V118G……………………..Braided Air Line from V093G to V098G

4KG Interlock Components

V007R…………………………………………..Interlock safety switch

V007RA………………………………………………………..Screw

V007RB…………………………………………………..Backing plate

V007T………………………………………………………..Lid plate

V007U…………………………………………………….Latch block

V007X……………………………………………………Lockwasher

V007W………………………………………………………..Screw

V007Y……………………………………………………Spacer plate

V007Z………………………………………………………..Screw

V007ZA…………………………………………………Lockwasher

V007ZB……………………………………………………..Washer

List of Grinding Barrels and Accessories

G-2-ND4KGML…………………………………..Grinding Barrel 4 kg, alloy-2, complete

G-1-ND4KGML…………………………………..Grinding Barrel 4 kg, alloy-1, complete

G-2-2KGML-1…………………………………..Grinding Barrel 2 kg, alloy-2, complete

G-1-2KGML-1…………………………………..Grinding Barrel 2 kg, alloy-1, complete

G-21500ML…………………………………..Grinding Barrel 1500mL, alloy-2, complete

G-11500ML…………………………………..Grinding Barrel 1500mL, alloy-1, complete

PS1400…………………………………..Grinding Barrel, PS1400, carbon steel, complete

G-2-1KGML-1…………………………………..Grinding Barrel 1kg, alloy-2, complete

G-1-1KGML-1…………………………………..Grinding Barrel 1kg, alloy-1, complete

G-21000ML…………………………………..Grinding Barrel 1000mL, alloy-2, complete

G-11000ML…………………………………..Grinding Barrel 1000mL, alloy-1, complete

G-2-500ML…………………………………..Grinding Barrel 500mL, alloy-2, complete

G-1-500ML…………………………………..Grinding Barrel 500mL, alloy-1, complete

G01-500ML…………………………………..Grinding Barrel 500mL, alloy-01, complete

GMS-500ML…………………………………..Grinding Barrel 500mL, Mild Steel, complete

G-2-250ML…………………………………..Grinding Barrel 250mL, alloy-2, complete

G-1-250ML…………………………………..Grinding Barrel 250mL, alloy-1, complete

G01-250ML…………………………………..Grinding Barrel 250mL, alloy-01, complete

GMS-250ML…………………………………..Grinding Barrel 250mL, Mild Steel, complete

GCS-250ML…………………………………..Grinding Barrel 250mL, Carbon Steel, complete

G-2-150ML…………………………………..Grinding Barrel 150mL, alloy-2, complete

G-1-150ML…………………………………..Grinding Barrel 150mL, alloy-1, complete

GCR-150ML…………………………………..Grinding Barrel 150mL, Ceramic,complete

GTC-150ML…………………………………..Grinding Barrel 150mL, Tungsten Carbide, complete

G-2-100ML…………………………………..Grinding Barrel 100mL, alloy-2, complete

G-1-100ML…………………………………..Grinding Barrel 100mL, alloy-1, complete

G01-100ML…………………………………..Grinding Barrel 100mL, alloy-01, complete

GMS-100ML…………………………………..Grinding Barrel 100mL, Mild Steel, complete

G-2–50ML…………………………………..Grinding Barrel 50mL, alloy-2, complete

G-1–50ML…………………………………..Grinding Barrel 50mL, alloy-1, complete

GMS–50ML…………………………………..Grinding Barrel 50mL, Mild Steel, complete

GCR–50ML…………………………………..Grinding Barrel 50mL, Ceramic,complete

GTC–50ML…………………………………..Grinding Barrel 50mL, Tungsten Carbide, complete

TRAY-50-1…………………………………..Adapter Tray to hold 1 Grinding Barrel, 50mL

TRAY50-3…………………………………..Adapter Tray to hold 3 Grinding Barrels,50mL

V-HANDLE…………………………………..Handle for 1Kg, 2Kg and 4Kg disk removal

O’Rings

V080A…………………………………..O’Ring for Grinding Barrel, 4 kg

V081…………………………………..O’Ring for Grinding Barrel, 1500mL

V081A…………………………………..O’Ring for Grinding Barrel, 2 kg

V081AA…………………………………..O’Ring for Grinding Barrel, 1kg

V083…………………………………..O’Ring for Grinding Barrel, 500mL(and 1000mL lids made before Nov 2010)

V083A…………………………………..O’Ring for Grinding Barrel, PS1400

V083B…………………………………..O’Ring for Grinding Barrel, 1000mL

V084…………………………………..O’Ring for Grinding Barrel, 250mL

V085…………………………………..O’Ring for Grinding Barrel, 150mL

V086…………………………………..O’Ring for Grinding Barrel, 100mL

V087…………………………………..O’Ring for Grinding Barrel, 50mL

V092…………………………………..O’Ring for Grinding Barrel, Ceramic 150mL

V093…………………………………..O’Ring for Grinding Barrel, Ceramic 50mL

WHEN ORDERING ONLY PARTS OF A GRINDING BARREL, PLEASE SPECIFY BY USING THE TERMS BOWL, LID, LARGE RING, SMALL RING, PLUG OR DISC – WHICHEVER APPLIES FOR THE SIZE OF BARREL YOU REQUEST. Use the following extensions:

ML – Complete Grinding Barrel

BO – Bowl Only

LI – Lid Only

DK – Disk Only

LR – Large Ring Only

SR – Small Ring Only

PL – Plug Only

Examples:

- G-2-250BO Bowl only, 250mL grinding barrel, alloy-2

- GCR-50PL Plug only, 50mL, grinding barrel, ceramic

- G-1-1KGML Complete 1 kg, grinding barrel, alloy-1