This last set of operating variables is very basic. There are only two, the PERCENTAGE of MOISTURE that is in the concentrate as it goes into the drier, (your filter cake humidity) and the TEMPERATURE that the drier is heated to. It is very evident that the wetter the concentrate the longer that it will take to dry. The RETENTION TIME, the time that the concentrate is in the drier is constant, therefore the only things that are adjustable are the temperature or the filter performance.

To close this chapter there are some indicators of performance and pointers for equipment safety that I would like to pass on. An operator with a little experience will visually be able to judge the moisture content of his finished product by its physical characteristics. If the concentrate is being discharged from the drier in small balls, there is a good possibility that it is too wet. This happens with some driers because the concentrate feed was wet and heavy enough to roll instead of tumble through the drier. The smaller the ball is the drier it will be. This can also be an indication that a portion of the flights are buried. In some operations this may not be a major factor in drying the concentrate however. The colour of the concentrate, and the amount of dust being produced are all indications of the concentrate dryness.

As I mentioned there are only two variables, one of them is heat control. There is an upper limit to how much heat that you can use unfortunately. If the internal heat of the drier becomes too great there is a danger of setting some types concentrates on fire. A concentrate fire is very hard to put out as they often generate all the necessary ingredients for a fire themselves. Another problem that heat will cause is warped drier shells. If the concentrate is set on fire inside the shell or even if the drier is shut down while it is hot the shell may warp. This is because with a fire the heat will not be even over the whole surface of the drier. The hotter portion of the metal will expand farther than the colder section. Why the shell will warp when it is shut down is due to the weight’ of the drier resting unevenly on the shell. If it is kept moving any warping will be evenly distributed.

As I mentioned there are only two variables, one of them is heat control. There is an upper limit to how much heat that you can use unfortunately. If the internal heat of the drier becomes too great there is a danger of setting some types concentrates on fire. A concentrate fire is very hard to put out as they often generate all the necessary ingredients for a fire themselves. Another problem that heat will cause is warped drier shells. If the concentrate is set on fire inside the shell or even if the drier is shut down while it is hot the shell may warp. This is because with a fire the heat will not be even over the whole surface of the drier. The hotter portion of the metal will expand farther than the colder section. Why the shell will warp when it is shut down is due to the weight’ of the drier resting unevenly on the shell. If it is kept moving any warping will be evenly distributed.

The last little warning is a personal one, some of the gasses that are generated by heating concentrate dangerous. The exhaust gas may collect along with the fumes from the drier. To prevent build-up of these fumes in the drier and to aid the drier in cooling down, it is a good idea to leave the drier shell and the blower run for a period of-time before shutting them down.

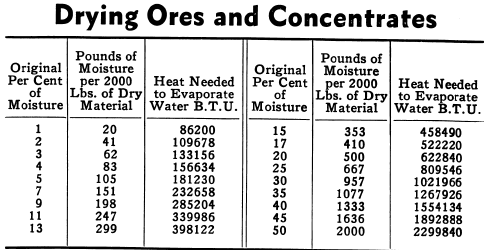

Specific heat of material for above data taken at 0.21.

Approximate B.T.U.’s in various coals:

Lignite……………………………………………..12,160

Sub-Bituminous………………………………..13,030

Bituminous………………………………………15,560

Anthracite……………………………………….14,070

1 gallon Fuel Oil=1 pound Coal.

Rotary driers have thermal efficiencies of from 50 to 75 per cent on ores. This must be taken into account when using the above table, which is figured at 100 per cent.