The conditioned pulp is run into a flotation cell, which is crudely a box with a stirrer, and a means of introducing air. Typically, the cell might contain 15-30% by volume of entrained air with bubbles ranging mainly from 0.1 to 5mm in diameter; the “pulp density” might be 25-40% of solids having a particle size ranging from 10-100um. The flotation grains are caught by bubbles and carried to the top of the cell, forming a froth, which is automatically scraped off over the “lip” of the cell, where it collapses and flows away in a launder. The frothing action is quite important. A moderate depth of froth is necessary to allow some back-drainage to take place, with release of non-floated particles which have been, unavoidably, entrained to some extent between the bubbles. Here is another reason why “slimes” are a nuisance – they remain too long in the water between the bubbles and so reduce the “grade” of the floated product.

The first stage of flotation of the pulp amounts to a quite short average “residence time” in the “rougher” cell before it passes out, largely depleted, from the bottom of the cell. In a conventional flotation plant no attempt is made to engineer a perfect separation in one stage. Instead, both fractions leaving the rougher are re-treated at least once in “cleaner” and “scavenger” cells, respectively. Scavenger cells, in effect, prolong the flotation time, while competition for bubble surface is reduced. The net of the recycling and re-treatraent is improvements in the separation (“grade”) and proportion of valuable minerals obtained (“recovery”). As the latter is usually a minor component of the ore, it is preferable to float it, in preference to floating the much greater proportion of gangue; but in some cases the gangue is floated (“reverse flotation”).

It is a characteristic feature of flotation plants that the cells are comparatively small, but rows and rows of them are run in parallel to increase through-put and in series to improve grade. If more than one mineral is to be extracted, the pulp is re-conditioned with other reagents and further stages of flotation are operated. The engineering is simple, continuous, amenable to adjustment, and needs little operator attention. The “concentrates” from flotation are generally filtered, washed, dried and bagged for transport as powders.

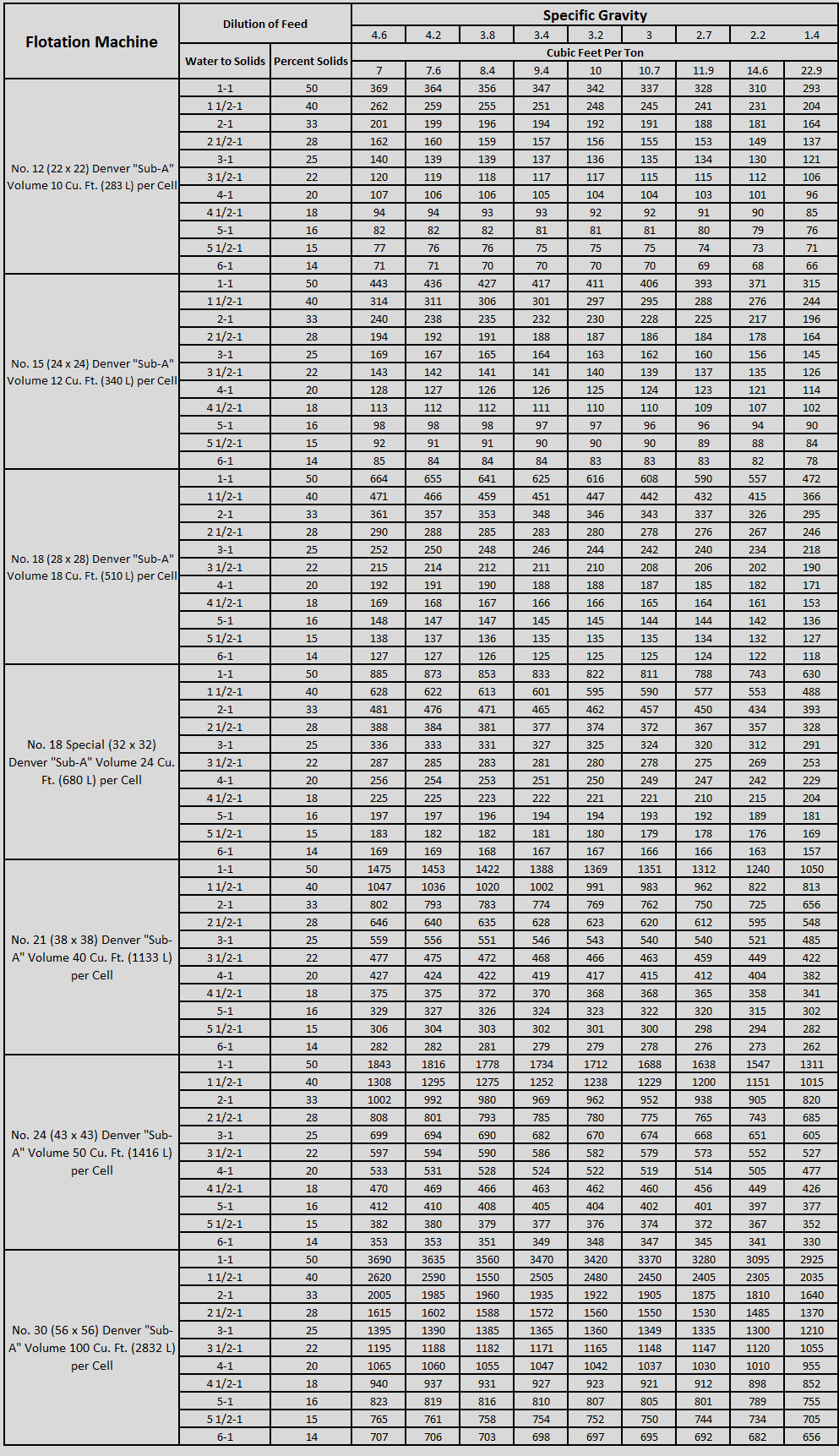

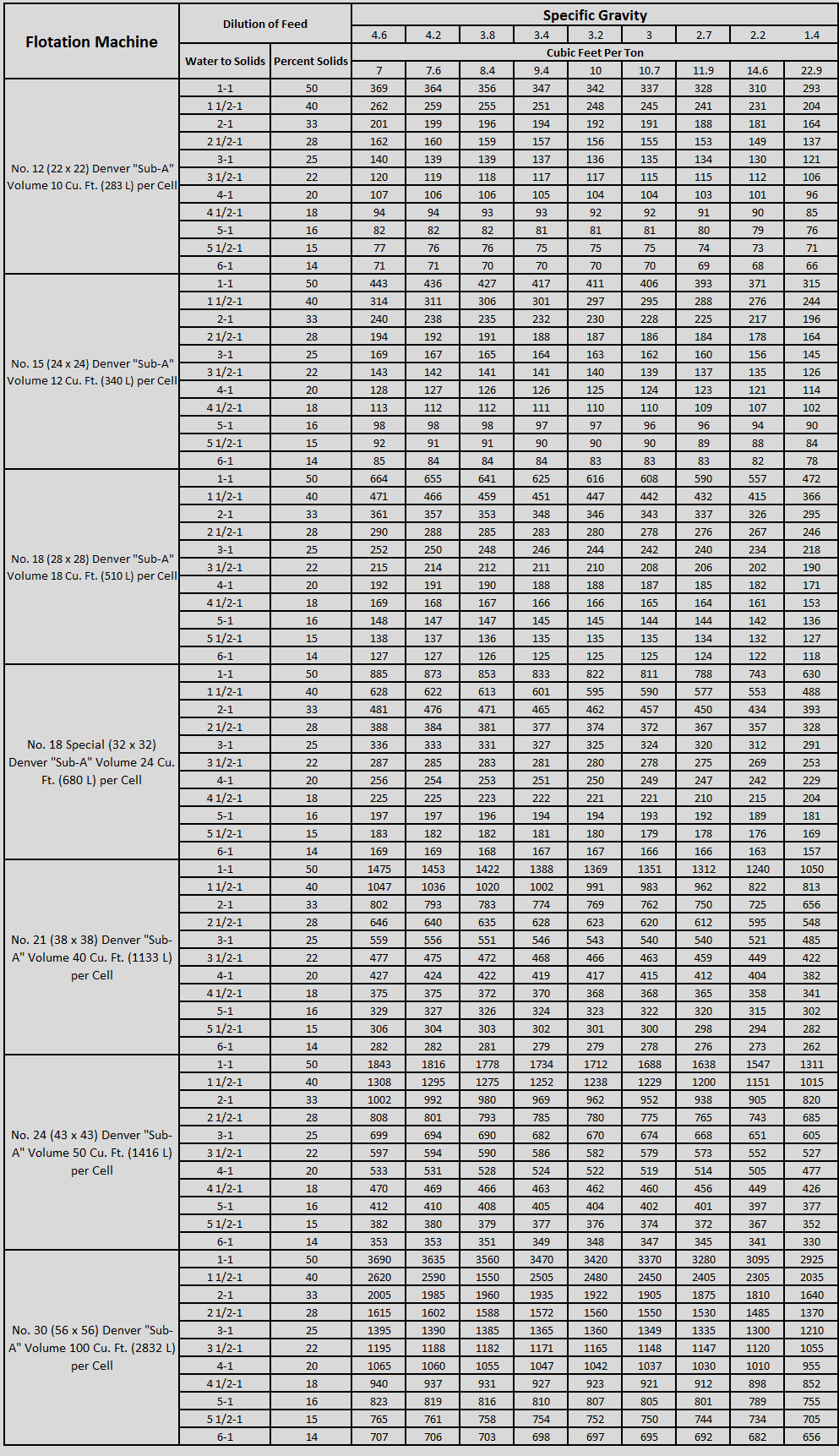

PROBLEM 1 – How many No 15 (24×24) Denver “Sub-A” Cells are required to treat 50 tons of gold or load ore per day, with treatment time 12 minutes, dilution 3 to 1; and SG. 3.0 ?

Tons (14 hours) x Treatment time (minutes)/Tabulated tonnage figure = 50 x 12/162 = 3.7 cells

- ANSWER – The result is 3.7 cells, thus use 4 No. 15 Denver “Sub A” Cells.

PROBLEM 2 – How many No. 18 Sp. (32×32) Denver “Sub-A” Cells are required to treat 125 tons of load-zinc ore per day, with treatment time 14 minutes for the lead, dilution 3 to 1% and with treatment time 16 minutes for the zinc dilution 3½ to 1. and sp. gr. 3.4 ?

- ANSWER – (lead) 125 x 14 / 327 = 5.4. thus use 8 No. 18 Sp. Cells.

- ANSWER – (zinc) 125 x 16-/281 = 7.2. thus use 8 No. 18 Sp. Cells.