DESCRIPTION

FEATURES AND BENEFITS

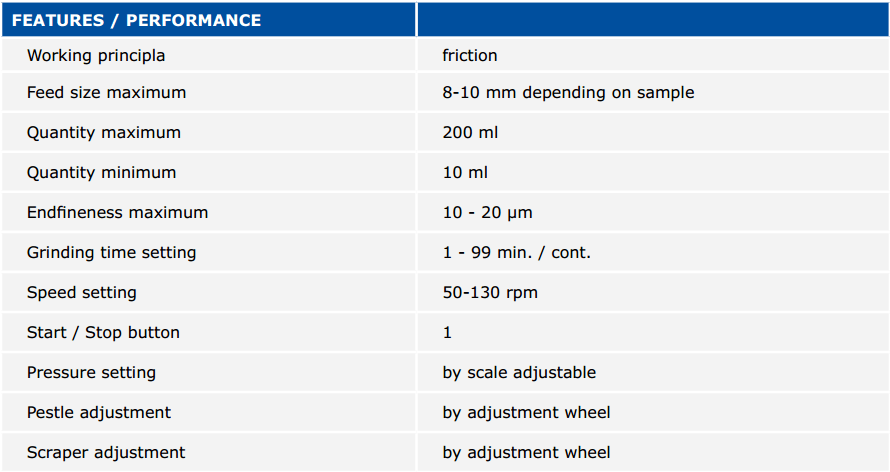

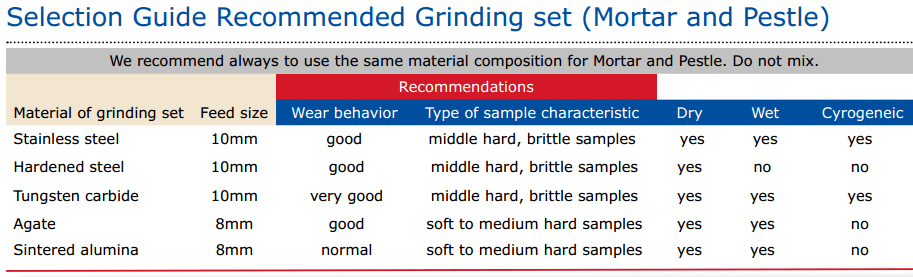

- 5 different grinding media available

- 3 different scraper materials available

- Quick and extremely easy to clean

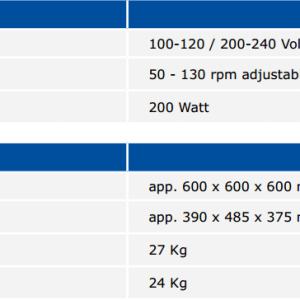

- Variable speed setting 50-130 rpm

- Digital time setting

- Digital speed setting

- No tool required to open

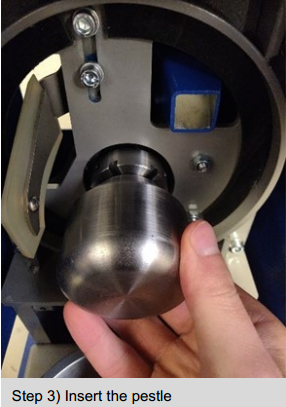

- No tool required to take off pestle

- No tool required to take off mortar

- Dust tight milling chamber

- Wet grinding

- Dry grinding

- Cryo grinding

- CE certified

APPLICATIONS

- Cocoa beans / chocolate paste etc.

- Food and animal food

- Maize, beans

- Creams, emulsions,

- Soil samples

- Minerals

- Glass, ceramics

- Cement clinker, cement

GRINDING MEDIA AVAILABLE IN 5 DIFFERENT MATERIALS

- Turbulent Blending

- Laminar Blending

- Liquid Dispersion

- Gas Liquid Dispersion

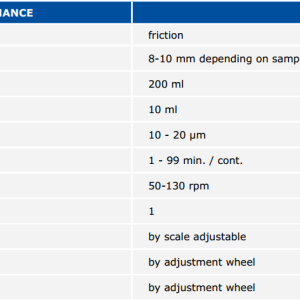

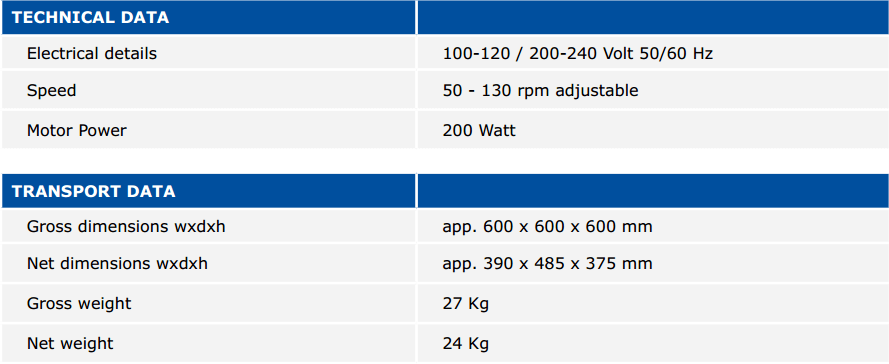

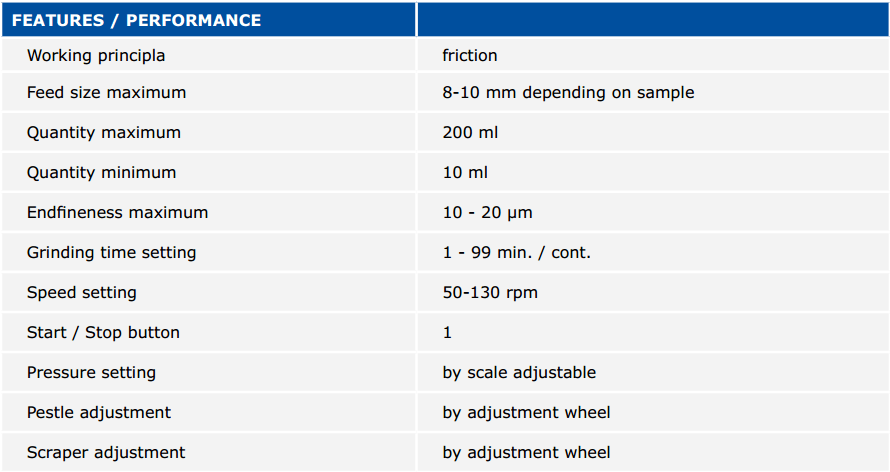

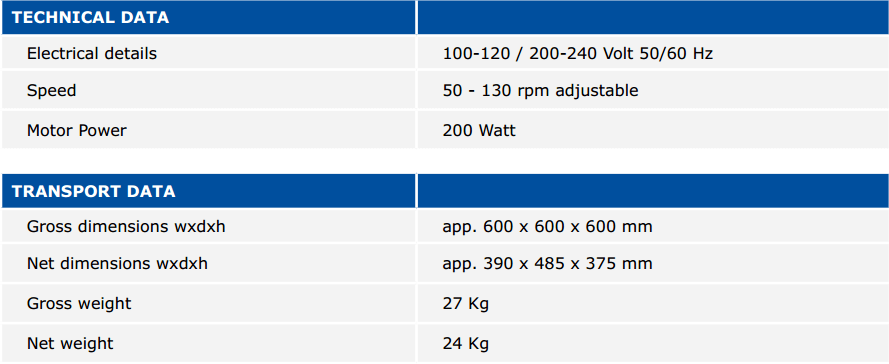

ELECTRIC MORTAR GRINDER MILL SPECIFICATIONS

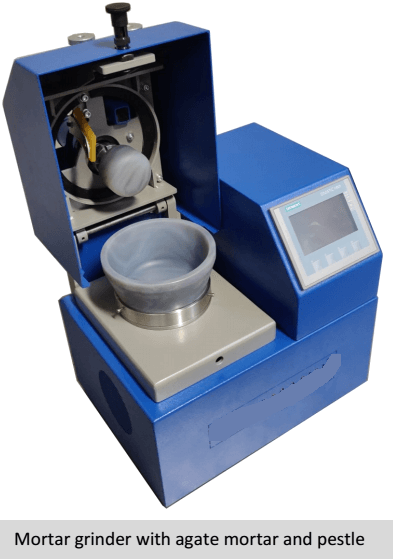

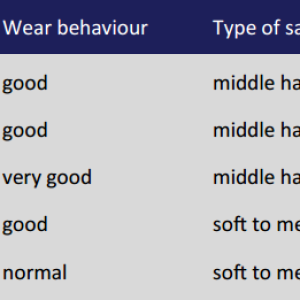

ELECTRIC MORTAR GRINDER

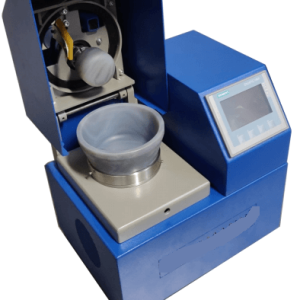

Universal, High Performance Mortar Grinder for processing of solid materials in dry, wet or cryogenic condition

- Dry Grinding / Wet Grinding / Ultra Fine Grinding / Cryogenic Grinding

- Mixing

- Cell disruption for DNA / RNA extraction

- The MG100 can handle samples from 10 up to 200 ml

A Superior Mortar Grinder engineered to reproducibly grind and mix sample volumes from 10 of up to 200ml.

HIGH OPERATOR CONVENIENCE AND MAXIMUM SAFETY

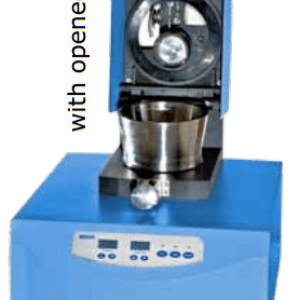

The Mortar Grinder is the central machine in a sample prep. Laboratory of today. This system is suitable for the fine grinding of any dry substance, as well as for suspensions with different viscosities for analysis, quality control and material testing. It is perfectly suitable for the homogenization of creams and pastes. Typically samples with a feed size of up to 8-10mm and a total batch of up to 200 ml (volume depending on the characteristic of the samples) can be ground down to 10-20µm.

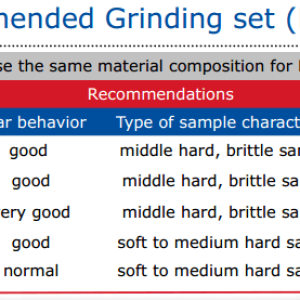

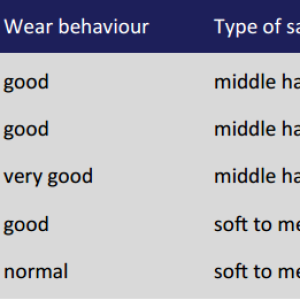

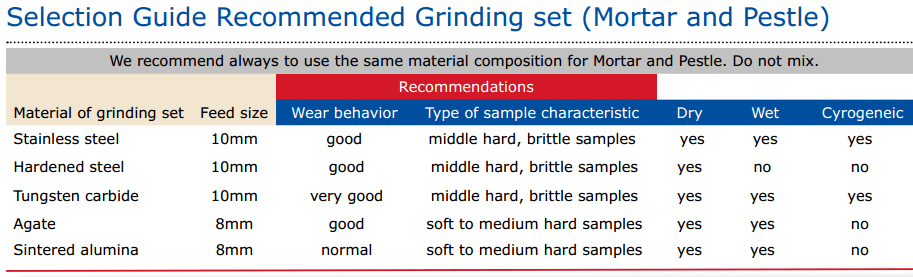

SELECTION GUIDE RECOMMENDED GRINDING SET (MORTAR AND PESTLE)

- Extremely easy cleaning

- Suitable for dry, wet & cryogenic grinding

- Possible to add and to remove sample material during the milling process via Cover inlet

- Representative results due to digital time and speed setting

- Precise and optimized results due to variable speed 50-130 rpm

- CE conform

- Meet all application tasks due to a wide selection of grinding tools for the mortar and the pestle.

- Meet all application tasks due to a wide selection of scraper materials (Vulkollan, Teflon, Beachwood)

- Positioning and removal of Mortar and pestle without tool

- Precise and reproducible pestle setting due to scale adjustment

- Solid steel housing

- Option of pre-crushing for coarser materials

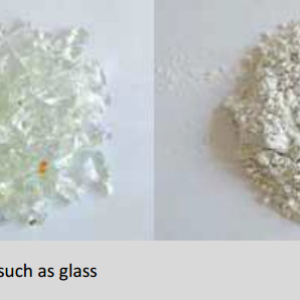

GRINDING AND MIXING EXAMPLES BEFORE / AFTER

Universal, High Performance Mortar Grinder for processing of solid materials in dry, wet or cryogenic conditions. A Superior Mortar Grinder engineered to reproducible grind and mix sample volumes from 10 up to 200ml.

Top Pressure Mechanism with scale and a variable speed setting 50-130 rpm, as well as a flexible scraper setting. Only due to the combination of this 3-key adjustment feature, a wide range of sample preparation tasks can be reached.

No other grinding system is easier to clean than the 911MPEMG100 Mortar Grinder. When the grinding process is finished, the mortar and pestle can be removed by a bayonet lock in order to perform a quick cleaning of the grinding tools.

High operator convenience and maximum safety

Maximum grinding performance and maximum safety are important for mills. Due to an integrated safety switch, the machine can only be started when the “Easy Lock Cover” is closed. The “Adjustment Mechanism” allows simple, fast setting changes and fine adjustment. The cover, as well as the housing, of the 911MPEMG100 is made from solid steel. The ergonomic design of the machine and the front panel ensure easy and simple setting of all working parameters.

Universal, high performance Mortar Grinder for processing of solid materials in dry, wet or cryogenic condition

- Dry Grinding/Wet Grinding /Ultra Fine Grinding/Cryogenic Grinding

- Mixing

- Cell disruption for DNA/ RNA extraction

- The MG100 can handle samples from 10 up to 200 ml

PERFORMANCE FEATURES MG 100

- Extremely easy cleaning

- Suitable for dry, wet & cryogenic grinding depending on grinding material

- Possible to add and to remove sample material during the milling process via cover inlet

- Representative results due to digital time and speed setting

- Precise and optimized results due to variable speed 50-130 rpm

- CE conform

- Meet all application tasks due to a wide selection of grinding tools for the mortar and the pestle.

- Meet all application tasks due to a wide selection of scraper materials (Vulkollan, Teflon, Beachwood) no tool required

- Precise and reproducible pestle setting due to scale adjustment

- Solid steel housing

- Option of pre-crushing for coarser materials

A Mortar Grinder engineered to reproducibly grind and mix sample volumes from 10 of up to 200ml

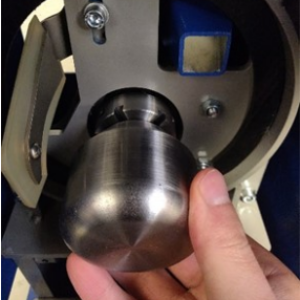

Method of operation

The Mortar Grinder Model MG100 is used to reproducibly grind, homogenize and mix a wide range of solid materials in dry / wet or cryogenic condition. The material to be processed falls into the Pulverizing area between Mortar and Pestle by top feeding via the opening which is at the inlet cover. The material is then pulverized and mixed between the Mortar inner surface area and the bottom of the pestle. In order to match the necessary top pressure with the requested end fineness and the breaking behaviour of the sample to be prepared the MG100 is equipped with and adjustable Top Pressure Mechanism with scale and a variable speed setting 50-130 rpm and a flexible scraper setting.

Only due to the combination of this 3 key adjustment features a wide range of sample preparation tasks can be reached.

No other grinding system is more easy to clean then the MG100 Mortar Grinder.

When the grinding process is finished the Mortar and Pestle can be taken out with a bayonet lock in order to perform a quick cleaning of the grinding tools.

Grinding, homogenizing, triturating

The Mortar Grinder is the central machine in a sample preparation Laboratory of today. This system is suitable for the fine grinding of any dry substance, as well as for suspensions with different viscosities for analysis, quality control and material testing. It is perfectly suitable for the homogenization of cremes and pastes. Typically samples with a feed size of up to 8-10mm and a total batch of up to 200 ml (volume depending on the characteristic of the samples) can be ground down to 10-20µm.

High operator convenience and maximum safety

The Mortar Grinder is the central machine in a sample preparation Laboratory of today. This system is suitable for the fine grinding of any dry substance, as well as for suspensions with different viscosities for analysis, quality control and material testing. It is perfectly suitable for the homogenization of cremes and pastes. Typically samples with a feed size of up to 8 -10mm and a total batch of up to 200 ml (volume depending on the characteristic of the samples) can be ground down to 10-20µm.

We recommend always to use the same material composition for Mortar and Pestle.

MORTAR GRINDER MANUAL

Foreword

Congratulations on your purchase of this Mortar Grinder. Only original replacement parts respectively purchased parts complying with the original state may be used. Guarantee claims are only valid if no changes are made to the original state of this Mortar Grinder. We assume no liability for damage caused by failure to comply with these instructions or by inappropriate behaviour. This technical manual may not be duplicated or passed on to third parties, either totally or partially

1.1 Supplied technical documentation

The following documentation was supplied together with the machine:

Operating manual for the Mortar Grinder, including:

CE certificate

1.2 Serial number

The machine number is located on the nameplate. Enter your serial number here:

This machine number must be stated when making any technical inquiries. The nameplate is located on the back of the machine.

DESCRIPTION AND PROPER USE OF MORTAR GRINDER

2.1 Description and proper use of the Mortar Grinder

This Mortar Grinder is intended for

- Dry Grinding / Wet Grinding / Ultra Fine Grinding / Cryogenic Grinding

- Laminar Blending / Liquid-Liquid Dispersion

- Mechanical Alloying

- Cell disruption for DNA / RNA extraction

- The MG100 can handle samples up to 200 ml

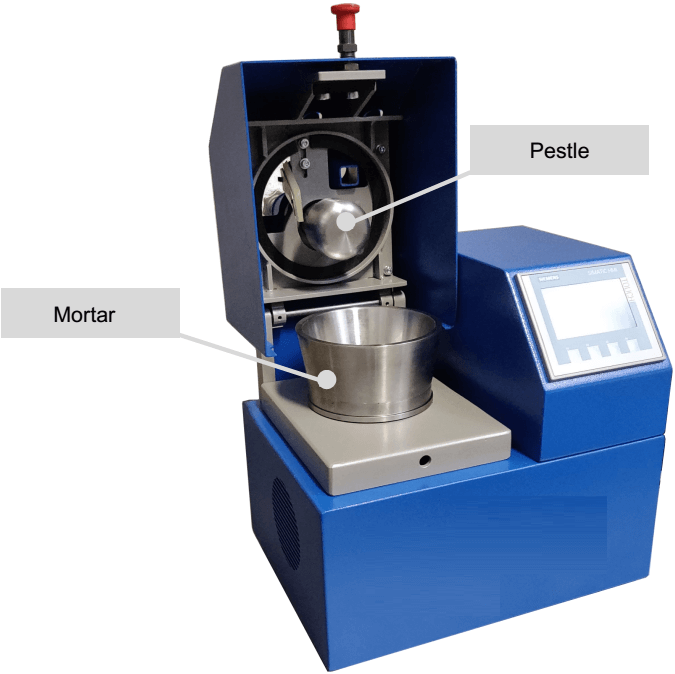

The Mortar Grinder consists essentially of a powerful drive with driven Mortar Plate. It can be loaded with various Mortar and pestle combinations.

2.2 Improper usage

The Mortar Grinder is designed to be used with properly fitted Mortar and Pestle always made of the same

material. If any other kinds of material are fed into the machine, this can cause major accidents or damage

to the Mortar Grinder.

Safety instructions

3.1 General safety instructions

The Mortar Grinder has been manufactured using state-of-the-art engineering and technology and complies with the

valid safety requirements of EU directive 98/37/EG on the point in time of delivery.

The original state of the machine may not be changed. Safety devices may not be changed, removed or bridged. All

maintenance and repair work may only be carried out by qualified staff when the machine is at a standstill and

disconnected from the power supply.

3.4 Safety symbols

Failure to comply with the sections of text marked in this way result in danger. Injuries are possible. Damage to the mill and accessories is possible, special care is required.

This symbol marks instructions for correct execution of certain jobs of work, e.g. that the work may only be carried out by an electrician.

Symbol for supplementary information and remarks.

3.3 Safety clothing

The operating staff at the machine must always use the personal safety gear prescribed by law and provided by the

employer. We recommend using safety gloves, working shoe’s and a face mask when working with dangerous material.

3.4 Requirements made of the operating staff

The staff responsible for operating and maintaining the machine must be trained and suitable for these jobs of work. Precision and safety in machine checks must be guaranteed. The responsible staff must have read and understood this operating manual.

There is an added risk of accidents during maintenance and servicing work. This is why all jobs of work must be carried out with the machine at a standstill by experienced and skilled staff capable of taking the safety precautions for major maintenance work.

The machine may only be operated, maintained and repaired by trained staff. In particular, these people must have read and understood the complete operating manual in the interests of all those involved. This is the only way to guarantee safe, trouble free operation.

3.5 General safety instructions

Only switch the Mortar Grinder on when the easy clamp system is tightened properly

Bring the Mortar Grinder Mill directly to its operating position.

3.6 Safety clothing

Observe the same safety precautions as for maintenance! Switch off the Mortar Grinder before cleaning, safeguard the main switch. Do not use corrosive, easily flammable substances as cleaning agents.

3.7 Maintenance

To be carried out only by qualified staff (see also 3.4). Wear safety gloves. Switch machine off. After maintenance, fit all the safety devices back in their correct positions and check that they function properly.

Check every month:

– State and proper function of the easy clamp system. Check O-rings

– Functions of the limit switches (only by the company electrician)

– Condition of the Mortar and the pestle.

Electrical equipment of the Mortar Grinder

4.1 Maintenance

In the case of malfunctions, interrupt the power supply immediately and secure it to prevent the machine being switched on again. Only use the fuses stated in the circuit diagram. Connection, maintenance and servicing should only be carried out by an electrician.

4.2 Electrical connection

The electrical connection should generally be carried out by an electrician. The works guarantee becomes null and void when the motors are mounted by the customer.

The motors are connected up according to the operating manual of the motor manufacturer.

Transport and erection of the Mortar Grinder

5.1 General transport information

Guarantee or compensation claims are null and void when the damage has been caused by improper transport or improper handling. Examine the Mortar Grinder for any signs of transport damage immediately after transport, have any such damage acknowledged in writing by the carrier, inform the insurance company and the supplier.

5.2 Weight and dimensions

Mortar Grinder dimensions:

1 carton with Inlay / on Pallet 700x750x700mm

Total gross weight: 52 kgs for transport (with steel mortar and pestle)

5.3 Erection and assembly

Check as follows:

- Check all fixing screws

- Check all safety fasteners, and remove any foreign bodies from the Milling chamber.

Check electric system (only by an electrician)

- Operating voltage using a voltmeter

- Electrical fuses

- Check electric cables for any signs of damage

- Check connections

5.4 Erection site

The machine can be easily moved within the laboratory or the workshop.

The following points must be observed at the erection site of the machine:

- A constant temperature must be guaranteed. It should not be under +5°C or above +40°C.

- The humidity may not exceed 85% continuously.

- The main switch of the Mortar Grinder must be freely accessible.

Taking the Mortar Grinder into storage.

The Mortar Grinder is to be stored in a dry room. Protect from the damp, from a corrosive atmosphere and from temperatures below +5°C and above +45°C.

Electrical connection

6.1 Connection

When connecting the machine to your local power supply source please pay attention to the information on the sticker at the rear of the machine showing the technical information.

These jobs of work may only be carried out by qualified staff. The connections must be completed carefully. Errors can pose a mortal danger. The connection regulations of the responsible power utility company must be observed.

- Connect up the machine according to the circuit diagram.

- Check proper position of Mortar and Pestle

6.2 Starting up the Mortar Grinder

Only start the Mortar Grinder with properly inserted Mortar and Pestle.

Operation

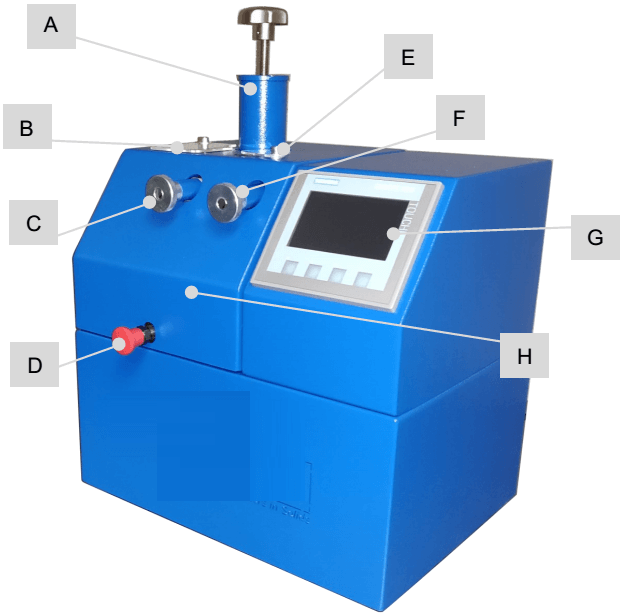

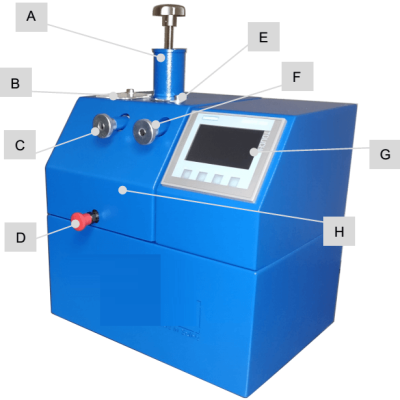

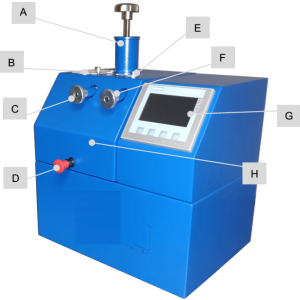

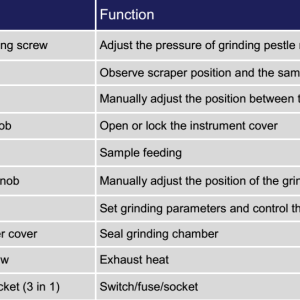

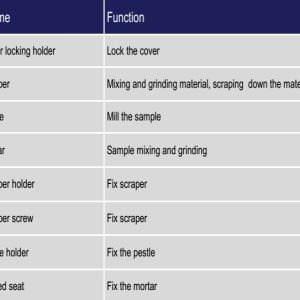

7.1 Control elements and their use

The machine can be easily moved within the laboratory or the workshop.

The following points must be observed at the erection site of the machine:

- A constant temperature must be guaranteed. It should not be under +5°C or above +40°C.

- The humidity may not exceed 85% continuously.

- The main switch of the Mortar Grinder must be freely accessible.

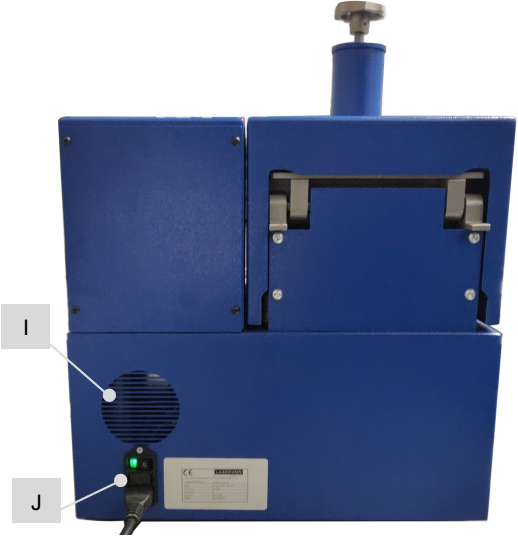

Functions Starting the MG100 The ON/OFF and switch G is located at the rear of the machine, Figure 2

The grinding parameters can now be selected and the machine is ready for operation. Push the START button.

The Motor starts and the Mortar base plate start the rotation.

When connecting the machine to your local power supply source please pay attention to the information on the sticker at the rear of the machine showing the technical information.

In order to guarantee a smooth running operation of the MG100 it is necessary that both Mortar and Pestle are inserted and made from the same material.

For example: Mortar and Pestle made from stainless steel or made Mortar and Pestle from Agate.

Attention: Never Mix the Material (Agate and Steel) because of breakage.

Make sure that the Mortar and pestle are properly in the Holders of the machine.

When removing and opening hot or cold grinding jars always wear protective gloves.

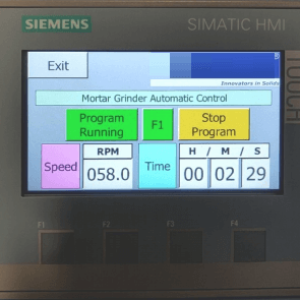

7.5 Program setting

Starting Screen

This is the starting screen for the installation.

Here you can select “Hand Controls” for manual input or select “Automatic System” for automatic.

Additional languages can be added on request

Hand control

Here you see the overview of the manual system.

With hand control you can start the machine and change the rpm and time during the run

Automatic control

This is the overview for the automatic system.

You can program up to 3 programs.

The first time you need to set the parameters and press “save program” afterwards the system will save the parameters and these won’t be needed to put in again.

You can load each program (after saving it) by pressing on the program number. Now the machine will load the parameters corresponding

After setting the parameters or after loading the program you can press Next. You will see overview of the program and from here you can press Start program after that the machine will start running the program. You can press Stop programs any time you like if you wish to stop the program

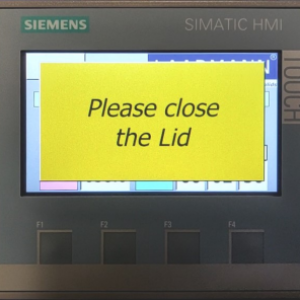

Safety

For safety measures the program will not start if not lid is not closed properly. If this happens close the lid or check if the cover locking knob is not locked completely

WORKING INSTRUCTIONS FOR OPERATION

8.1 Selection Guide Mortar and Pestle

This declaration of conformity confirms compliance of the above mentioned equipment to the relevant sections of the following European Directives:

91/368EWG European machine guideline

73/23/EWG EC Low Voltage Guidelines

EN 292, 294, 418 Safety guidelines

VBG 1,4,5 en 22 General electrical facitilies

89/336/EEC Electromagnetic Compatibility Directive (EMC)

EN 5008-1-1992 Emissions

EN 50082-1-1992 Immunity

EN 60204-1 Part 1 Safety of Machinery – Electrical Equipment of Machines

WARNING:

This equipment is required to be operated strictly in accordance with the instructions given in the operating manual supplied with the product. All supply voltages and frequencies as stated on the rating plate must be used.

This conformity certificate will lose its validity in case of:

- Usage of unlicensed spares

- Usage of unlicensed accessories

- Any self made modifications of the machine