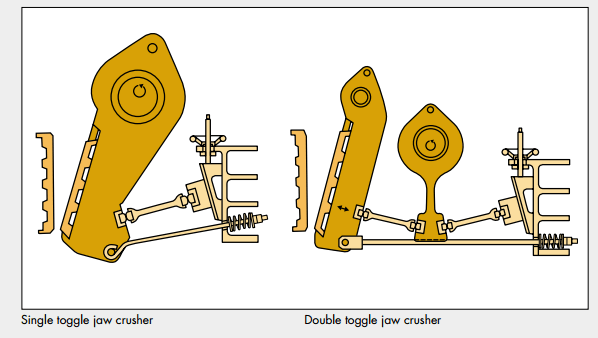

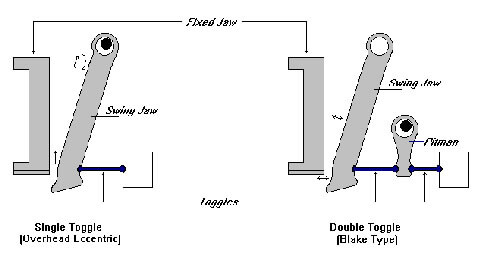

A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers. The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw.

A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers. The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw.

Anyway, double toggle jaw crushes are really more about where the eccentric is located than anything. In a double toggle jaw crusher, the eccentric is located behind the swinging jaw. This has two main effects, – it keeps the eccentric out of harms way because there is no shock loading from the rock being crushed being transferred to the eccentric shaft and bearings. The other effect is a limited plane of motion for the swinging jaw which contributes to its lack of productivity. The jaw moves like a swinging door that is hinged at the top and is being pushed open and pulled closed at the bottom. One toggle plate goes from the bottom of the eccentric arm to the bottom of the swinging jaw, the other toggle plate goes from the opposite side of the bottom of the eccentric arm to a fixed point at the very back of the jaw crusher frame.

|

Single Toggle Jaw Crusher |

Double Toggle Jaw Crusher |

In contrast, the single toggle jaw crusher has fewer shafts and bearings and only one toggle which goes from the bottom of the swinging jaw to a fixed point at the back of the jaw crusher. The eccentric is located at the top of the swinging jaw and is part of the shaft. The advantage of this is that the jaw has two motions that are happening at the same time. It has the same swinging door motion that the double toggle has, but also has the up and down motion from the eccentric.

Jaw Crushers: Blake & Single-Toggle VS Overhead Eccentric Types

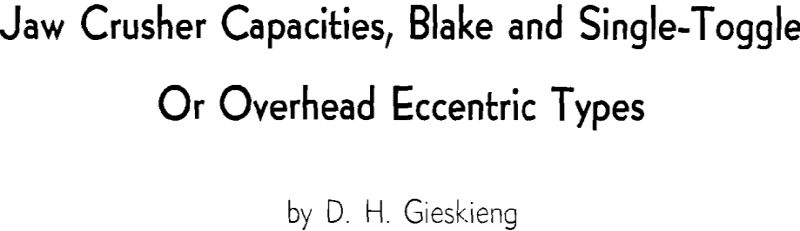

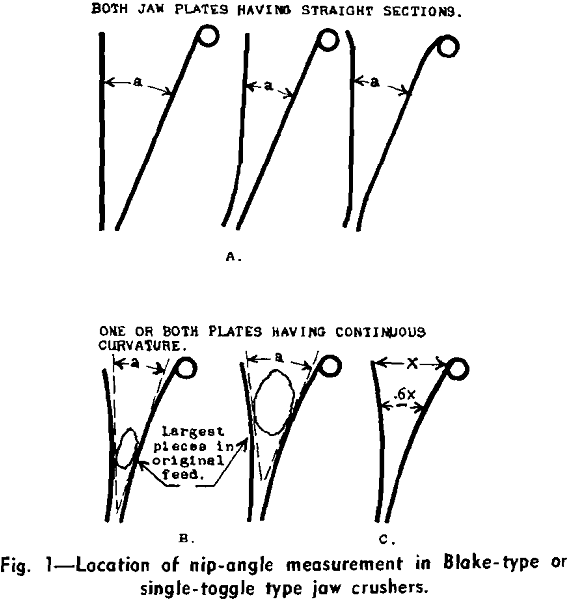

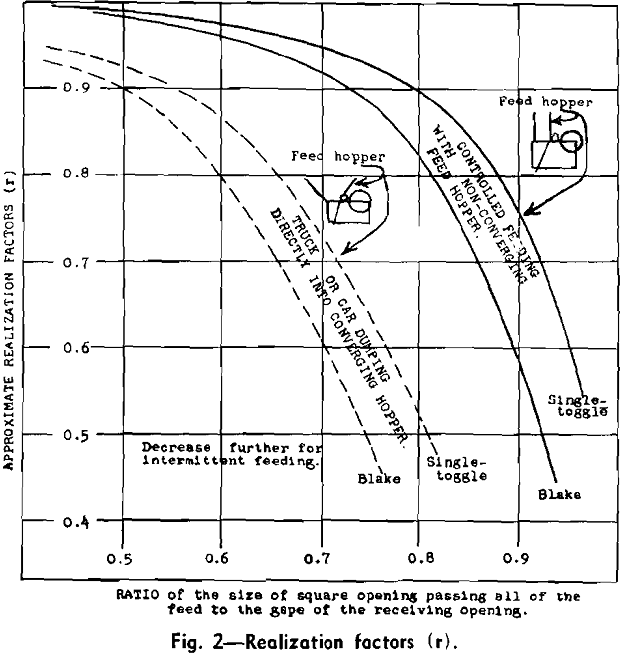

The advent of curved jaw crusher wearing plates made an approach other than segmental layout analysis desirable for prediction of capacities. For some time it had been known that the drawing board capacities of crushers using these plates had to be considerably modified by complicated experience factors to achieve agreement with results. Because these apparent capacities could be readily increased severalfold by minor crushing chamber shape changes, it was necessary that the utmost precaution be taken in predicting capacities of jaw plates modified for nonchoking, special wear characteristics, or any other reason.

While this paper is concerned principally with standard type single-toggle crusher capacities, the evaluation of data obtained with these machines is simplified by comparative reduction to the 10 x 7 in. Blake-type equivalents upon which the summary of the preceding paper was made. Convertibility of data from one type of crusher to the other also tends towards confirmation of both. The agreement of these data is sufficient to be considered complimentary. Consequently the feed factors, f, previously reported for Blake crushers are slightly adjusted to an average with the single-toggle crusher results.

Blake-type equation:

C = f·d·w·y·t·n·a·r………………………………………………………[1]

Single-toggle type equation:

C = f·d·w·y·t·n·a·e·r……………………………………………………[2]

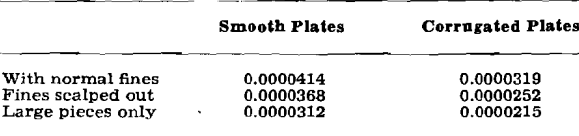

where C is the capacity in short tons per hour through the crusher, f is a feed factor, dependent upon the presence of fines in the feed, and the surface character of the jaw plates used.

Values of f:

d is the apparent density of the broken product in pounds per cubic foot. (If the true specific gravity of the feed is known, 40 pct voids may be assumed and d becomes 37.4 times sp gr).

w is the width of crushing chamber in inches.

y is the open side setting of the crusher, in inches. In the case of corrugated jaw plates it is measured from the tip of one corrugation to the bottom of the valley opposite.

t is the length of jaw stroke in inches at the bottom of the crushing chamber. It is the difference between open and close-side settings.

n is rpm, or crushing cycles per minute.

a is the nip-angle factor.

To bring the Blake and single-toggle type crusher capacity test results to common terms for evaluation, all data are converted to terms of 10 x 7 in. Blake-type performance at conditions of 100 lb per cu ft, 10 in. chamber width, 250 rpm, 0.65 in. stroke, 3-in. open-side setting, and 18° nip-angle. (The nip-angle of the 10×7 in. Blake is 18° at 3-in. setting.) The single-toggle crusher performances are also divided by the eccentric throw to bring this effect to unity.

In the Blake-type crusher tests, no capacity variation was noted for materials of different crushabilities, even though a wide range of materials was tested. These feeds had impact strengths ranging from 2.8 to 31 ft lb per in. of thickness as measured by the Bond method, (potash, coke, soft hematite, limestones, traprock, taconites.)

Greater differences in crushability-capacity effect than those just discussed for single-toggle type crushers have been reported by investigators working with small Dodge-type crushers. However, these crushers have rubbing motion between the jaws at the discharge, and in addition have very little jaw stroke at the discharge.