Table of Contents

Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers:

Crusher Selection

- For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher. Between these capacities, you have a choice. Source: Chris Ottergren

- For a hard rock mine application below 540 tonnes/hour, a jaw crusher is more economical. Above 725 tonnes/hour, jaw crushers cannot compete with gyratory crushers at normal settings (6 -10 inches). Source: Lewis, Cobourn and Bhappu

- For an underground hard rock mine, a gyratory crusher may be more economical in the case where it’s required daily production exceeds 8,000 tonnes of ore. Source: Jack de la Vergne

- If the hourly tonnage to be crushed divided by the square of the required gape in inches is less than 0.115, use a jaw crusher; otherwise use a gyratory. (If the required capacity in metric TPH is less than 162 times the square of the gape in metres, use a jaw crusher.) Source: Arthur Taggart

Crushing in Mineral Processing - Nearly all crushers produce a product that is 40% finer than one-half the crusher setting. Source: Babu and Cook

- The product of a jaw crusher will have a size distribution such that the -80% fraction size (d80) is slightly less than the open-side setting of the crusher. For example, if the open- side setting is 6 inches, the d80 product size will be 5¾ inches. Source: Unknown

- In a hard rock mine, the product from a jaw crusher will tend to be slabby, while the product from a gyratory crusher may tend to be blocky, the latter being easier to convey through transfer points on a conveyor system. Source: Heinz Schober

- Impact crushers (rotary or hammer mills) have the capacity for high reduction ratios (up to 40:1), but are rarely applied to hard rock mines. Since they depend on high velocities for crushing, wear is greater than for jaw or gyratory crushers. Hence, they should not be used in hard rock mines that normally have ores containing more than 15% silica (or any ores that are abrasive). Source: Barry Wills

Crusher Design

- The approximate capacity of a jaw crusher for hard rock application at a typical setting may be obtained by multiplying the width by 10 to get tonnes per hour. For example, a 48 by 60 crusher will have a capacity in the order of 600 tph when crushing ore in a hard rock mine. Source: Jack de la Vergne

- The capacity of a jaw crusher selected for underground service should be sufficient to crush the daily requirement in 12 hours. Source: Dejan Polak For most applications, 7:1 is the maximum practical reduction factor (ratio) for a jaw crusher, but 6:1 represents better design practice. Source: Jack de la Vergne

- A well-designed jaw crusher installation has the lip of the chute overlapping the throat of the vibrating feeder by 400 mm (16 inches) to prevent spill resulting from the inevitable blowback of wayward fines. Source: Jean Beliveau

- For most applications, 6:1 is the maximum practical reduction factor (ratio) for a cone crusher, but 5:1 represents better design practice. Source: Jack de la Vergne

- Corrugated liner plates designed for jaw crushers (to avoid a slabby product) result in shortening liner life by up to two-thirds and they are more prone to plugging than smooth jaws. Source: Ron Doyle

- Manufacturers tend to use rules of thumb to de-rate crusher capacities for the treatment of highly competent ores that display high Bond crushing work indices (CWi).

One such rule is the following: de-rate = (16/CWi)^0.5

However, care is required when using this rule as CWi test methods vary and simplistic approaches do not address all of the relevant issues. Source Ausenco

Crusher Installation

- The crushed ore surge pocket beneath a gyratory crusher should have a live load capacity equal to 20 minutes of crusher capacity or the capacity of two pit trucks. Various Sources

- It will take six months to excavate, install, and commission an underground crusher station for a typical jaw crusher. For a very large jaw crusher or a gyratory crusher, it can take nine months. Source: Jim Redpath

- The desired grizzly opening for an underground jaw crusher is equal to 80% of the gape of the crusher. Source: Jack de la Vergne

- The maximum feed size for a jaw crusher should be about 85% of the gape. Source: Arthur Taggart

- The combination of a jaw crusher and a scalping grizzly will have 15% more capacity than a stand-alone jaw crusher. Source: Ron Casson

- As a rule, scalping grizzlies are rarely used anymore for (large) primary crushers. The exception is when ore contains wet fines that can cause acute packing in a gyratory crusher. Source: McQuiston and Shoemaker

- The product from jaw crushers will tend to be less slabby and more even-dimensioned without a scalping grizzly, since slabs do not pass through so readily under this circumstance. Source: A. L. Engels

- Removal of the scalping grizzly for a primary jaw crusher can cut the liner life by 50%. It also makes it more difficult to clear a jam when the jaws are filled with fines. Source: Ron Doyle

Crusher Costs

- The total cost of a jaw crusher installation underground may exceed six times the cost of the crusher itself (purchased new), while on surface the factor is usually between three and four. Source: P. White and H. Lang

- With a typical 6:1 reduction ratio, the power consumption of a large jaw crusher (48 by 60) is approximately 1.8 tons per horsepower-hour (2.2 t/kWh). Source: Arthur Taggart

- The power consumption of a 42-inch gyratory crusher is approximately 2.4 tons per horsepower-hour (2.9 t/kWh). Source: Arthur Taggart

- Power consumption of a jaw crusher when idling is about 50% of full load, for a gyratory it is approximately 30%. Source: Richard Taggart

The Crusher’s Rock Breakers

- The capacity of a hydraulic rock breaker is higher (and the operating cost lower) than a pneumatic rockbreaker. For these reasons, most new installations are hydraulic, despite the higher capital cost. Source: John Kelly

- For underground production rates less than 2,000 tpd, it may be economical to size theore underground with rockbreakers only, otherwise, an underground crusher is usually necessary when skip hoisting is employed. Source: John Gilbert

- The operating cost for a stand-alone rockbreaker will be approximately 30% higher than it is for a crusher handling the same daily tonnage. Source: John Gilbert

- The capacity of one rock breaker on a grizzly with the standard opening (± 16 by 18 inches) is in the order of 1,500-2,000 tpd. Source: John Gilbert

- For skips that fit into a standard 6 by 6 shaft compartment, the maximum particle size that is normally desired for skip hoisting is obtained when run-of-mine muck has been passed through a grizzly with a 16-18 inch opening. Skips hoisted in narrow shaft compartments may require a 12-14 inch spacing, while oversize skips may handle muck that has passed a 24-30 inch spacing. Source: Jack de la Vergne

- A pedestal-mounted rockbreaker installed should be equipped with a boom that enables a reach of 20 feet (6m). Source: Peter van Schaayk

https://www.911metallurgist.com/blake-type-jaw-crusher

The addition of secondary crushing to an existing circuit are that:

- Reducing the F80 (80% of the feed size) to the SAG mill by 10mm will result in a 3-6% increase in SAG mill throughput, with the magnitude

depending on the ore characteristics and the mill operating conditions; Source Ausenco - reducing the F80 will also result in an improvement in overall comminution-circuit energy efficiency when treating competent ores. Bond

calculations define the efficiency of a fine stage-crush ball mill circuit as 1.0 to 1.2 depending on ball mill feed size, and some SABC (SAG/ball mill/pebble crusher) circuits operating with an efficiency of 1.3-1.4 or higher on coarse feed. If the coarse feed size is reduced, the circuit efficiency will approach that of the stage-crush and ball mill circuit.

Hence, if the JKDropWeight test Axb parameters (a measure of rock competency) are less than about 40, then secondary crushing is worth considering. Source Ausenco

More:

Grinding Rule of Thumb

Froth Flotation Rule of Thumb

Mineral Processing / Metallurgy Rule of Thumb

Hard Rock Miners Handbook – Edition 3 published by McIntosh Engineering in June 2003.

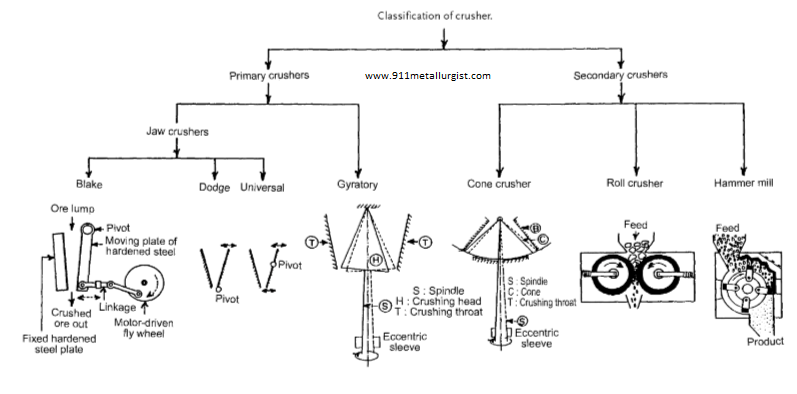

Area of Application

Use jaw crushers for hard materials but shift to cone crushers when hardness Mohs < 8 but not for sticky materials.

Jaw crusher: feed diameter 0.1 to 1.5m; reduction ratio 5:1 to 10:1; capacity 1 to 300kg/s; Mohs hardness < 9 [reduction by compression].

Gyratory crusher: feed diameter 0.75 to 1.5m; reduction ratio 5:1 to 10:1, usually 8:1; capacity 140 to 1000 kg/s; Mohs hardness <9. More suitable for slabby feeds than jaw crusher. [reduction by compression].

Roll crusher: feed diameter 1 cm: reduction ratio 5:1 to 10:1; capacity 0.3 to 20 kg/s: Mohs hardness < 7.5. Suitable for softer, friable and non-abrasive materials. Ok for wet and sticky materials.

Cone crusher and short head cone: feed diameter < 25 cm; reduction ratio 5:1 to 10:1 usually 7:1; capacity 5 to 300 kg/s: Mohs hardness < 8. Usually secondary or tertiary crusher.

Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to 10:1; capacity 0.3 to 50 kg/s.

Rules of Thumb in Engineering Practice. Donald R.Woods

https://www.911metallurgist.com/crushing-industry-vocabulary