As indicated in the introduction to this paper, it is a sequel to that which i gave to the last annual meeting in Atlanta in march, this paper goes further into aspects of crushing and screening, primarily from the standpoint of circuit control. By proper control over the use of crushing energy, we will be able to produce finished products from feed materials utilizing minimum capital for the lowest cost of production.

Discussion

The crushing and screening plant is part of most mineral concentrating operations and is normally followed by further size reduction circuits involving grinding mills. Comminution costs are always significant in the total cost of production of mining plants, The design and operation of any plant should be accomplished to minimize these costs as well as those to build the facility.

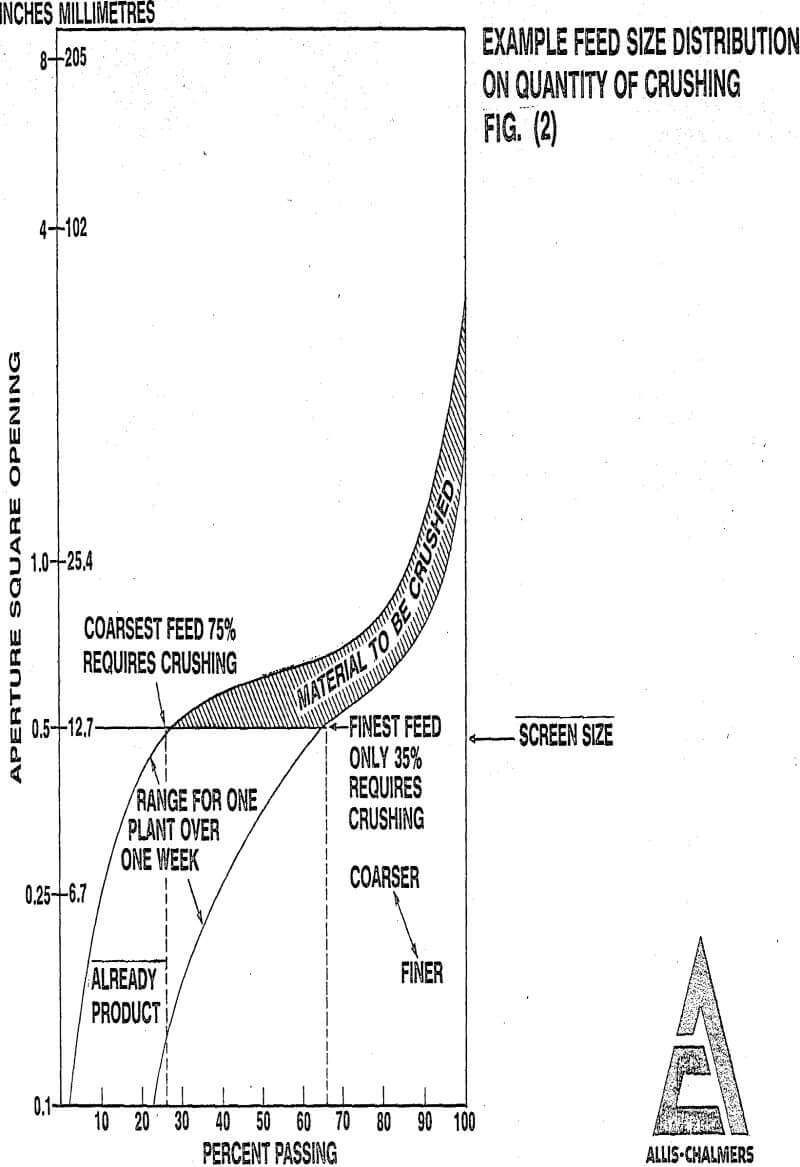

The output from a crushing plant in both quantity and degree of size reduction will be a function of the energy applied to the feed material. The more energy we have available, the more finished product we can manufacture or the finer we can reduce a given quantity of ore.

New Control System From Allis-Chalmers

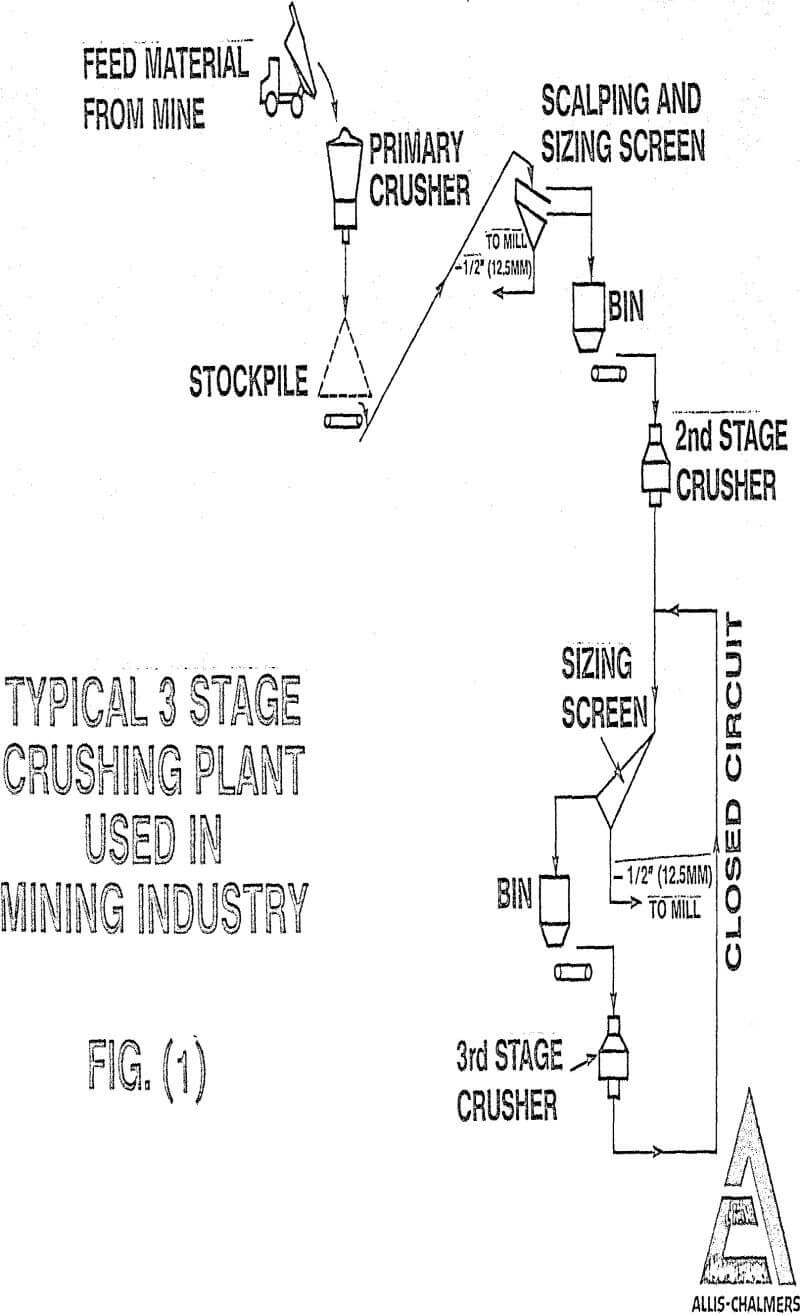

For optimization of crushing and screening plant operation, there is one aim, viz, to control the quantity and rate of energy applied to the ore. This can only be achieved by designing and controlling the plant to cater for variations in the feed material as previously discussed.

Plants are normally run in either one of two modes:

- Maximum reduction to be imparted to feed for subsequent processing, For this, maximum energy per unit of feed is the operating criteria.

- Maximum quantity of a given sized product. For this mode no more energy than that necessary to reduce material to the required size should be applied if production costs are to be minimized.

The plant consists of normal components presently utilized in crushing and screening plants, but we believe the control system and the method of arranging the energy balance to be unique. The diagram for simplicity shows a two-stage cone crusher reduction operation, but the system can be applied to any number of crushing stages.

This fluctuating rate of product being discharged from the first scalping screen reports quickly to product storage whilst the oversize will take a longer period to pass through the crushers and closed circuit screening system before it reports as product. This time difference will result in fluctuations to the tonnage of material going to product storage.