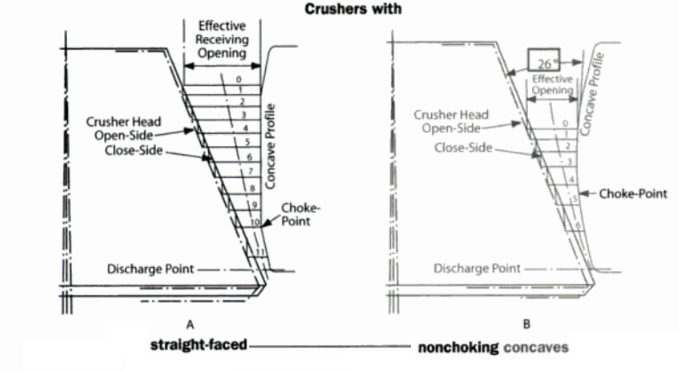

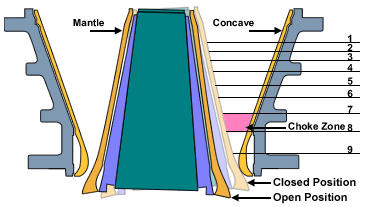

When used for primary or coarse secondary crushing service, the type of crusher described is usually fitted with the style of concave shown on the upper left. These are known as “standard” or straight-face concaves, which have been the standard type of liner ever since the gyratory crusher came into popular use. The distinguishing features of this type of crusher concave are:

- The receiving opening, for any given size of crusher, is at a maximum.

- The choke-point (point of minimum capacity) is at the discharge opening.

- The ratio of reduction varies for different sizes, ranging from about 5 to 8 and averaging about 6.5 for sizes from 8″ to 42″ inclusive. These ratios are based upon the use of standard-throw eccentrics.

Usually the primary crusher is selected on the basis of size of receiving opening and capacity. Often, the gyratory crusher with sufficiently large receiving opening will have ample capacity for the job. Furthermore, the permissible minimum discharge setting for the standard gyratory is usually small enough to make an acceptable secondary feed. For these reasons the standard crusher is, as stated before, usually supplied with straight-face concaves for primary crushing service.

There are some secondary crushing applications where maximum receiving opening, for any given size of machine, is desirable. For such applications straight-face concaves are indicated, provided of course that the crusher so fitted will have sufficient capacity for the job in hand. On the other hand, most secondary and some primary crushing jobs require maximum capacity and maximum ratio of reduction, rather than maximum receiving opening. The standard gyratory crusher has been adapted for such applications by the introduction of an interesting and important change in the shape of its crushing chamber, regarding which we shall have more to say under the subject of “non-choking concaves.” for the optimum working of crushers.

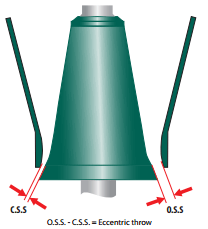

There are of course certain limiting factors which govern the proportions of the crushing chamber in these standard gyratory machines. One of these, the ratio of reduction which can safely be made in any given machine, has already been mentioned. As the ratio of reduction is simply the ratio of receiving opening to discharge opening, it follows that this limitation is directly related to the safe minimum discharge setting. All crusher manufacturers establish what are considered to be safe minimum settings for the different sizes of crushers of their manufacture. Published capacity tables for gyratory and jaw crushers generally list capacities at settings down to and including these minimum openings. The practice for gyratory crushers is to predicate these minimum settings upon the use of standard-throw eccentrics; i.e., throws which experience has proven to be right for each particular size of crusher.

Gyratory Crushers Maintenance