As the Crusher Concave Liners and Mantle Wear out there is a period when the crusher won’t be as efficient as it could be. This can be a very frustrating period for the operators. Since the throughput drops and operators have to work harder, usually doing the same thing over and over again. Unfortunately to get the most from the equipment requires that there is one hundred percent wear on the parts before they are replaced.

As the Crusher Concave Liners and Mantle Wear out there is a period when the crusher won’t be as efficient as it could be. This can be a very frustrating period for the operators. Since the throughput drops and operators have to work harder, usually doing the same thing over and over again. Unfortunately to get the most from the equipment requires that there is one hundred percent wear on the parts before they are replaced.

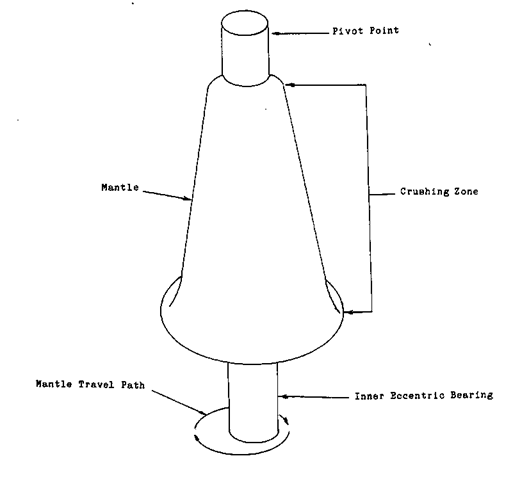

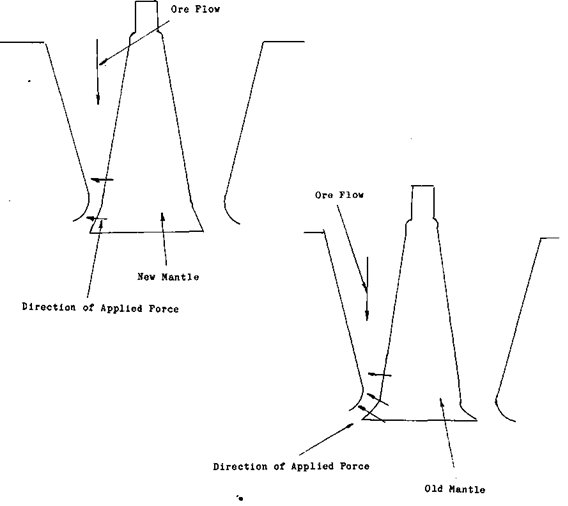

A perfect example of this is the wear on the concave liners and the mantle. The angle between the concave liners and the mantle is at its best operating position when they are new. As time and tonnage go by, both wear. Soon the pattern that the ore takes through the crusher begins to change. This is due to wear causing a LIP to be formed at the bottom of the mantle. When the formation of this lip passes a critical point the force of the crushing action begins to be directed upwards restricting the normal flow of ore downwards. The lip that has been formed is also preventing the fines from dropping through quickly enough to create the needed space for the new ore in the gyratory crushing chamber.

Normal wear and tear on the equipment will cause many problems for the operator. Leaking oil lines, loose drive belts, worn air clutches slipping, leaking air valves, these things all add up to more work and slower production. It is this type of problem that justifies the necessity of the operators circuit check. A sharp eyed, curious operator will spot many of these problems before they become serious enough to hamper production and cause the crew extra work.

https://www.911metallurgist.com/css-crusher-close-side-settings