Table of Contents

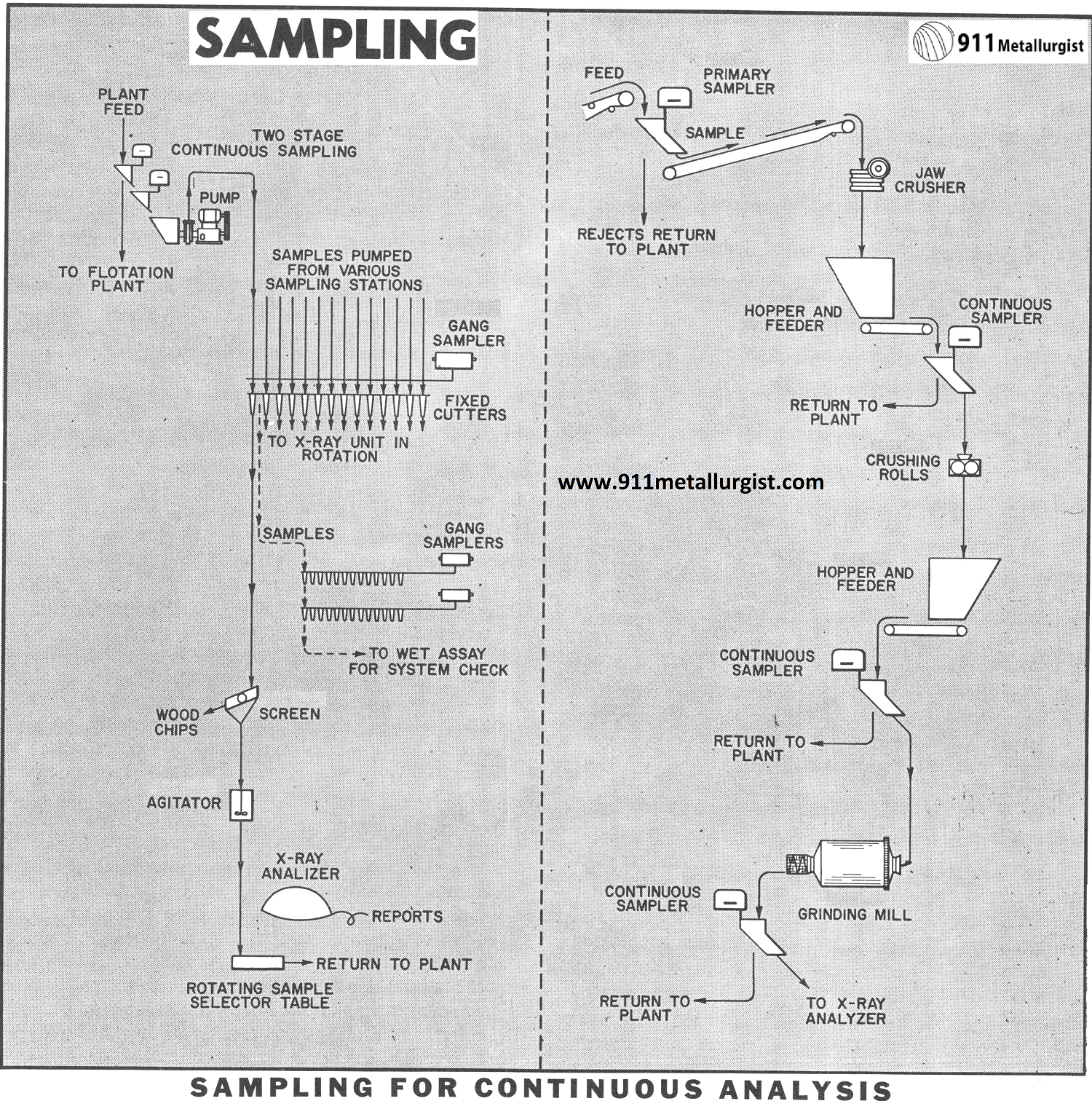

Development and use of on stream analysis for both wet and dry processes promises great advantages in processing and quality control.

In many cases the volume handled by an on stream analyzer must be far less than the total stream volume. Moreover, the accuracy of the analyzer report depends directly on the small sample presented to the analyzer. Therefore the method employed to withdraw the proper amount of material from the stream and prepare the small volume of feed required by the analyzer is most important. On stream analyzers frequently represent sizable investments, yet their reports can be no more reliable than the sample which is analyzed.

Multi-station analysis requires coordination of sample delivery to the analyzer. Time lag between sampling and delivery of the sample to the analyzer is frequently critical. Sample identity must be retained so the report can be translated to a specific condition existing in the main stream.

SAMPLING FOR WET ANALYSIS

Many problems with dry sampling systems do not exist in wet systems for in most cases the slurry represents material that can be presented to the analyzer without additional processing. Standard sampling devices can be used. The wet sample – handling system requires careful pump engineering to retain the sample identity. Pump sump design and pipe line velocity must prevent settling out of solids.

Multiple sampling stations can be used to feed a centrally located on-stream analyzer. Reports from the analyzer, in most cases, are practically immediate and lengthy chemical assays are normally not required. In this way the plant system can be analyzed and controlled while the material from which the sample was taken is still in the process. This procedure provides balance and controlled quality specifications.

SAMPLING FOR DRY ANALYSIS

Preparation of the sample to meet the requirements of the analyzer is the governing factor in most dry sampling systems. Greater analytical accuracy is secured from finely sized material (usually —200 mesh) than is secured by analyzing coarse material. This means size reduction is usually involved. Size reduction methods are best determined by laboratory testing since no two problems represent identical factors.

Continuous systems require dependable equipment and a “weak link” in the form of a pulverizer or grinder that is out of adjustment or in need of repairs could close down an entire system of elaborate and expensive controls.

Factors to be considered in sampling and sample preparation for dry systems are shown on the flowsheet. Sampling is normally on a continuous basis. Standard samplers and sample cutters are usually adequate and their use reduces the cost of a sampling system.

Multi-stage sampling is employed to secure a large control sample which is subsequently reduced in both size and bulk in following stages. A primary sampler removes from the main feed stream a sample of sufficient volume to be representative of the total coarse material. This coarse material sample is metered into the sampling system from a feed bin to a crusher for reduction in size.

FLOWSHEET NO. 1-Sampling for Wet Analysis

The wet system illustrated in this study is typical of many applications for continuous on-stream analysis.Here samples of slurry are taken at various points in the plant. The number of sampling stations depends on the flowsheet and quality control desired. Size of solid particles in the slurry can be accommodated by the analyzer. A sampling station at each point consists of a primary sampler operating continuously with the sample cutter moving completely across the stream. This sample cutter consists of continuous discharge container with parallel blades moving through the stream at a uniform speed and gives a representative sample. A secondary, continuously operating, sampler cutter is used to reduce the volume of the primary sample further to the correct volume to be pumped.

The sample is pumped from each sampling station to a central point for X-ray analysis. The pump sump and piping are sized to give enough velocity to the pulp to prevent settling or segregation of solids in the pipe. Pump and pipe are designed to minimize contamination due to corrosion or abrasion. Piping and hose are specified so that oils will not accumulate on the surface. Care must be taken to control frothing at all points.

The continuous samples arriving at the analyzer station are cut by a gang-type sample cutter to provide increment samples of the correct volume for the analyzer. Each increment sample is screened to remove wood chips and tramp oversize prior to going by gravity to its small agitator, which acts as a holding tank to keep the solids in suspension. The agitators feed the analyzer in sequence. Samples are analyzed, for example, every two minutes in mechanical rotation giving a total turn around time of 26 minutes for 13 stations. If operation requires more frequent analysis at one station, the sample from this point is analyzed in or out of sequence as required.

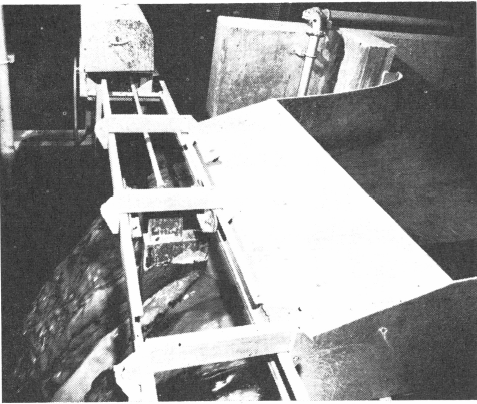

Automatic Sampler with wet sample cutter on end carriage track.

Automatic Sampler with wet sample cutter on end carriage track.

FLOWSHEET NO. 2-Sampling for Dry Analysis

The primary sampler is designed to cut a wide stream of large-size solids of varying diameters. Heavy abrasion-resistant wearing lips are provided on the sample cutter to minimize wear and provide parallel cutter lips. Stainless steel is frequently specified for its corrosion resistance and self-cleaning characteristics.

Crusher discharge is delivered to a hopper-feeder which meters the material thus eliminating surges to the continuously operating secondary sampler. All sample reject material is returned to the main process.

A roll crusher is shown as the secondary crusher but a hammer mill, gyrator crusher or even a small jaw crusher may be indicated by test work.

Throughout the dry size reduction system dust control and other devices to retain sample identity must be considered.

A grinding mill or continuous pulverizer, depending on nature of the solids, is used for reducing material to all 200-mesh for presentation to the analyzer. Open- circuit grinding has advantages in reducing time lag and retaining sample identity to the greatest possible degree.

The 200-mesh material is again sampled to reduce the bulk to a volume suitable for presentation as a volumetric ribbon for the analyzer.

Compare BOXA-II-III & Outotec Courier C5/6i SL

| No | Description | Courier 5i SL | BOXA-II & BOXA-III | Courier 6i SL |

| 1 | Analysis method | WDXRF+EDXRF | WDXRF+EDXRF | WDXRF + EDXRF |

| 2 | Element range | The element range is from Calcium to Uranium (atomic numbers 20 to 92) | The element range is from Calcium to Uranium (atomic numbers 20 to 92) | The element range is from Calcium to Uranium (atomic numbers 20 to 92) |

| 3 | Numbers of simultaneous assays | 11 elements and Density | 6 elements and Density | 11 elements and Density |

| 4 | Numbers of MXA | 2 | 4 | 4 – requires Expansion Panel |

| 5 | Sample streams | 12 | 24 | 24 |

| 6 | Measurement time | 30. . .60 Seconds per stream | 15. . .30 Seconds per stream | 15. . .30 Seconds per stream |

| 7 | Sensitivity | For most elements, changes of 0.01% can be detected at 1% level with a probability 95% from a homogenous sample. | For most elements, changes of 0.01% can be detected at 1% level with a probability 95% from a homogenous sample. | For most elements, changes of 0.01% can be detected at 1% level with a probability 95% from a homogenous sample. |

| 8 | Short term stability | In specified operating circumstances, the measured intensity stabilized is 0.3%. | In specified operating circumstances, the measured intensity stabilized is 0.2%. | In specified operating circumstances, the measured intensity stabilized is 0.1%. |

| 9 | Long term stability | The long term instrument drift is compensated by automatic internal reference sample measurement. | The long term instrument drift is compensated by automatic internal reference sample measurement. | The long term instrument drift is compensated by automatic internal reference sample measurement. |

| 10 | High Accuracy | Minor concentrations:4~6% Major concentrations:2~4% |

Minor concentrations:3~6% Major concentrations:1~4% |

Minor concentrations:3~6% Major concentrations:1~4% |

| 11 | Primary sampler control | yes | yes | yes |

| 12 | Flow rates | 70~300L/min(70~200) | 50~300L/min(70~200) | 70~300L/min(70~200) |

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.