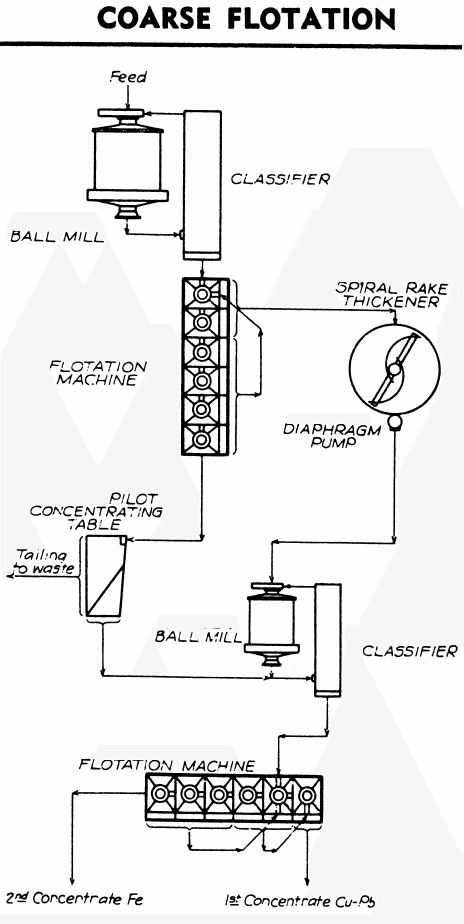

DESCRIPTION: Coarse flotation followed by regrind of coarse rougher concentrate and selective flotation or cleaning. Coarse flotation tailings and reground rougher concentrate are processed over a shaking table for precious metals.

ORE TREATED: Ores wherein the minerals can be freed from the gangue at a coarse mesh and subsequently separated from each other after finer grinding.

ADVANTAGES: For low cost operation of a selective plant wherein two concentrates are produced, this flowsheet has the advantage of eliminating fine grinding on the bulk of the ore. As an illustration, assume the ore being treated is a sulphide ore with chalcopyrite and pyrite containing gold values in both minerals, and that the minerals are freed from the gangue at a coarse mesh. The first flotation machine following the coarse grind produces a rougher concentrate containing all the minerals. These minerals are reground to free the chalcopyrite from the pyrite, and selective flotation or cleaning is carried out at a finer mesh in the second machine which gives a high-grade copper concentrate leaving a gold-iron concentrate product or an iron residue if gold is not a factor.

PROCESSING COMMENTS: When the ore contains any free gold, the Mineral Jig should be used in both primary and secondary (regrind) grinding circuits to remove this free gold since depressing reagents used for selectivity in sulphide separation also affect fine gold particles. Use of a Mineral Jig results in greater recovery of precious metals where present. See this Flowsheet.