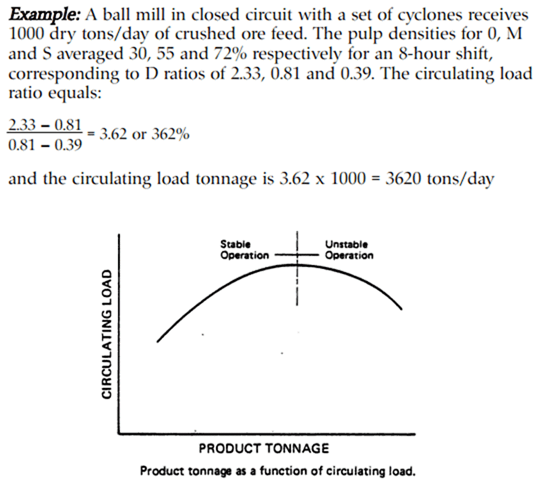

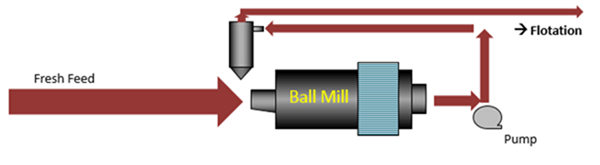

Here is a formula that allows you to calculate the circulating load ratio around a ball mill and hydrocylone as part of a grinding circuit.

For example your ball mill is in closed circuit with a set of cyclones. The grinding mill receives crushed ore feed. The pulp densities around your cyclone are sampled and known over an 8-hour shift, allowing to calculate corresponding to circulating load ratios and circulating load tonnage on tons/day or tons/hour.

This is %Solids/Densities Based Circulating Load Calculation Method obtained from the pulp/slurry around your hydrocyclone.

Cytec Handbook

Cytec HandbookWhy have a large circulation load:

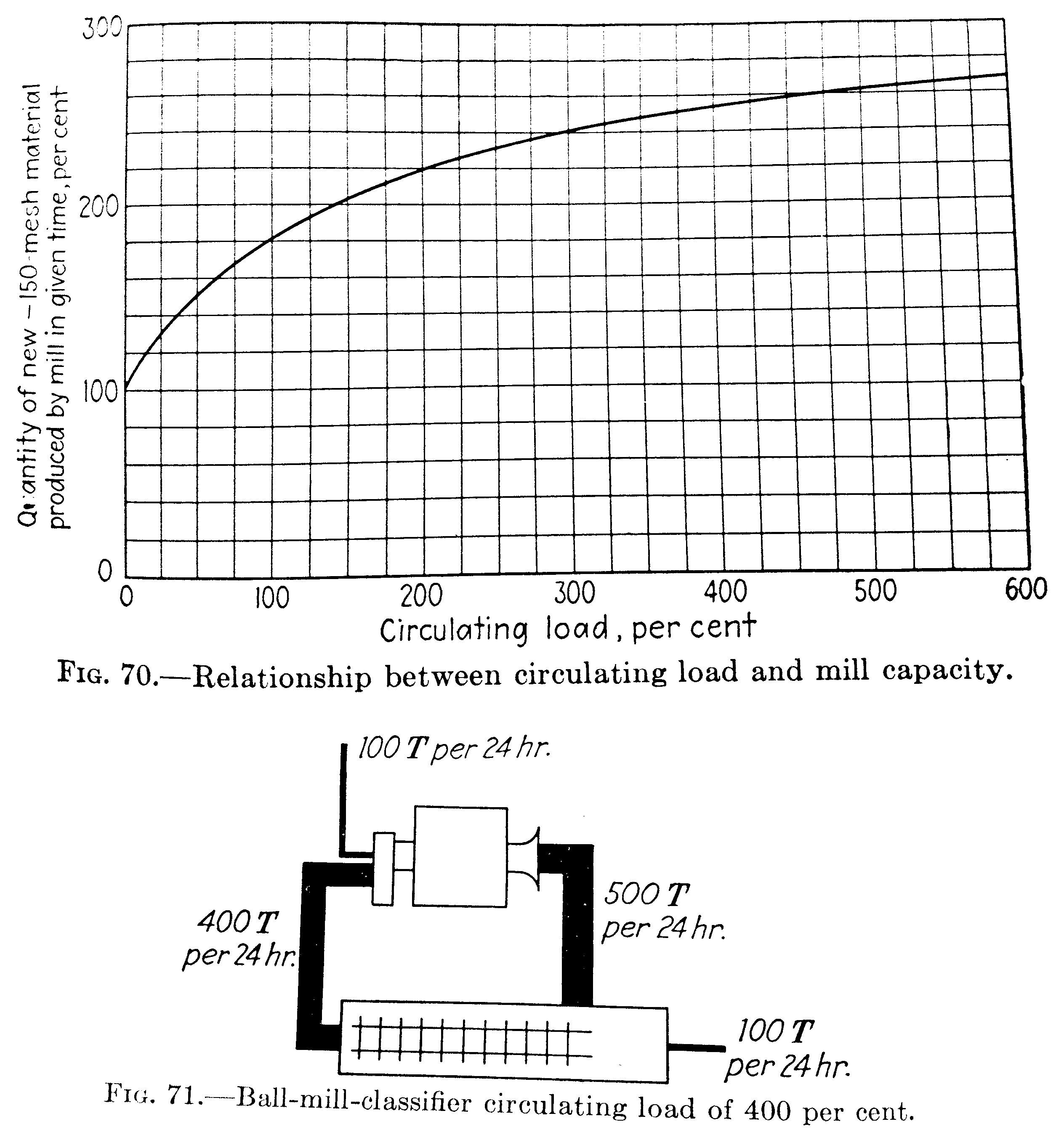

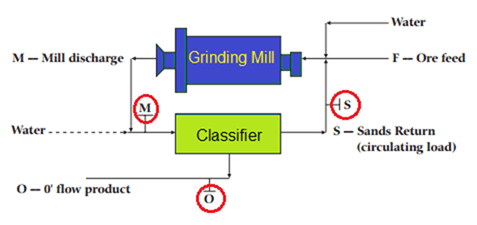

If a product all finer than a certain critical size is required, the capacity of the ball mill is increased considerably by using it in closed circuit with a classifier and this increase is made still greater by increasing the circulating load in between the ball mill and the classifier (Fig. 70). In practice, circulating loads between ball mills and classifiers are rarely less than 200 per cent and frequently exceed 700 per cent. It may appear strange at first sight that the circulating load between a mill and classifier producing, for example, 100 tons of finished product per day can be as much as 400 tons or more, but this will be made clear by Fig. 71. The trend to the use of higher and higher circulating loads in ball-mill-classifier circuits has resulted in certain mechanical requirements in ball mills, classifiers, and auxiliary equipments.

Arthur Taggart