The centrifuge modeling technique is a powerful tool for geotechnical engineering in general. It has been used for over sixty years to model soil behavior. Regarding phosphatic clays, centrifuge research has been actively conducted in the last decade by several investigators to predict the field consolidation of these clays. In this technique, a physical model is built with an at-rest weight of up to 1000 lb which is mounted in a large centrifuge (12-15 ft. radius). The model is spun so that the soil model experiences an acceleration of Ng (N times acceleration of gravity, g). The scaling is that if the model is one foot high, the soil will experience a level of stresses equivalent to a column of sediment of N ft. high, or a factor of N. More importantly, the time for consolidation is equivalent to N 1.6-2.0. Hence, the life of the disposal area can be modeled in the laboratory in a matter of hours.

Recently, other researchers have used the centrifuge to predict the consolidation behavior of flocculated clays. In their research, the data was fitted to a mathematical model similar to the ones used by soil engineers.

Mathematical Models

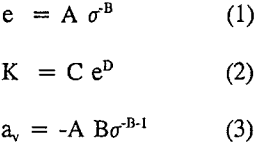

Another method of predicting the consolidation behavior of soli-like material is the use of mathematical models after certain parameters have been determined by laboratory testing. In this regard, several theories have been utilized. However, most of these theories have limitations including the complexity of the developed governing equations. In addition, three dimensional models are still to be developed. To avoid the problem of solving complex equations, several computer programs have been developed to provide numerical solutions. However, it is necessary to input the constitutive relationships of the material; specifically, compressibility and permeability. In general these relationships can be approximated empirically by :

Where:

e = void ratio = volume of water/ volume of solids,

σ = effective stress,

K = coefficient of permeability,

av = coefficient of compressibility,

A,B,C,D = empirical coefficients (material property constants) determined from laboratory testing.

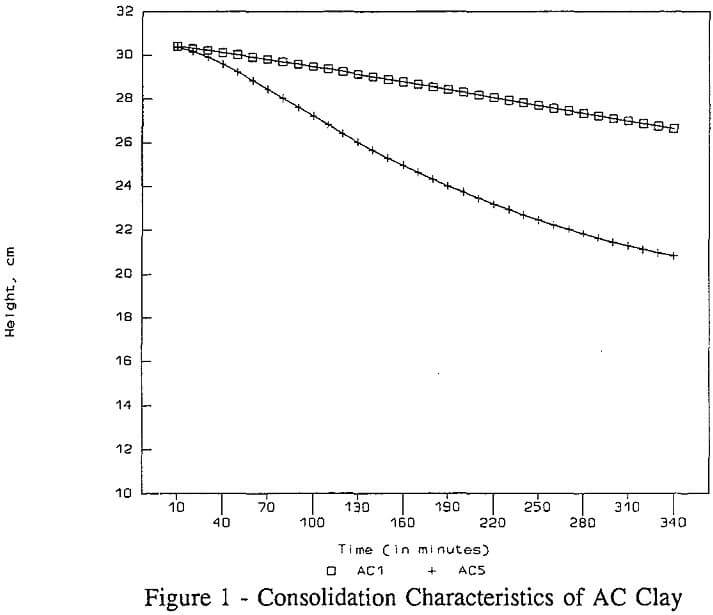

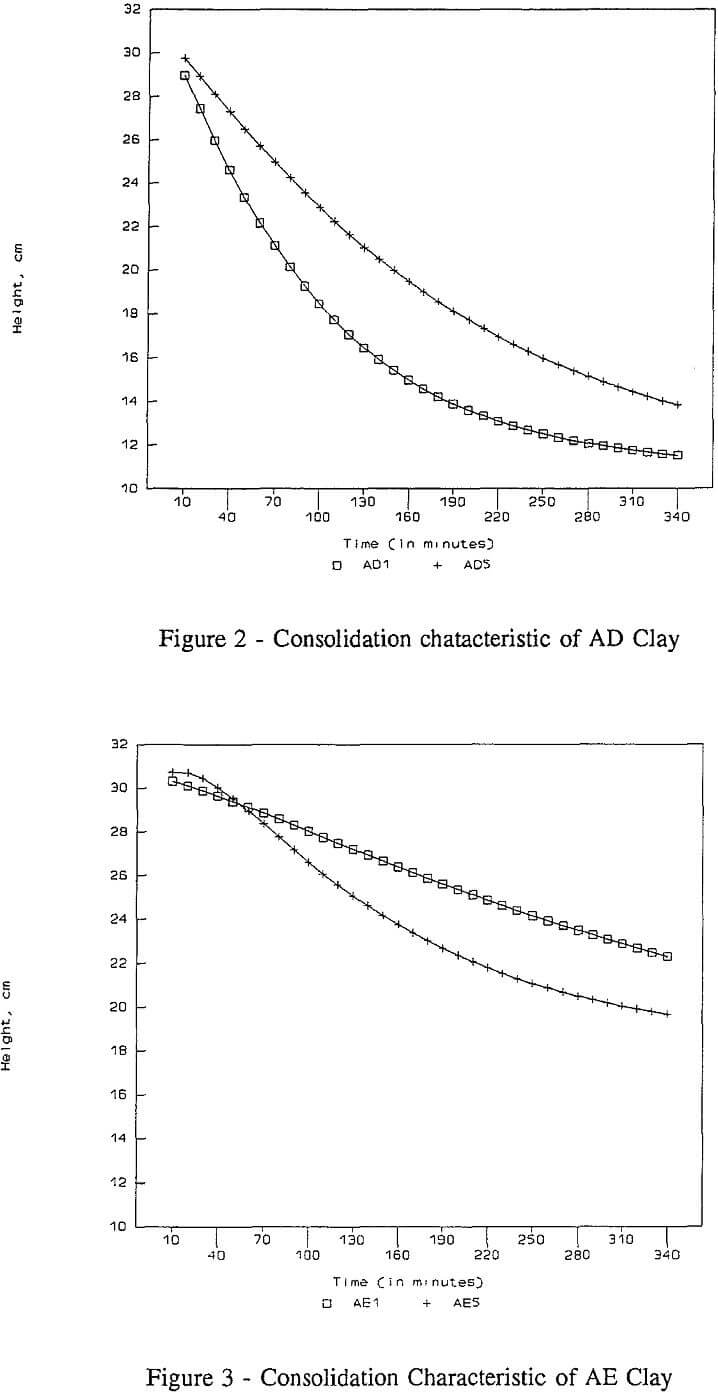

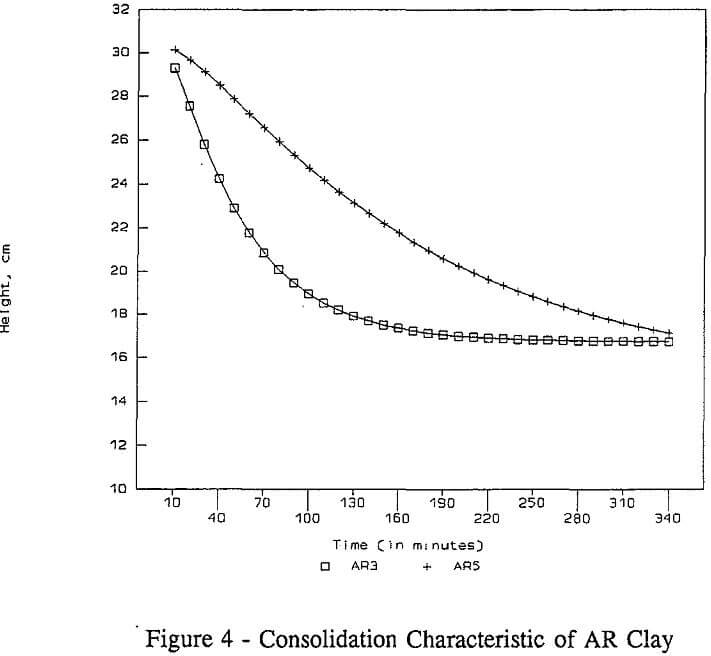

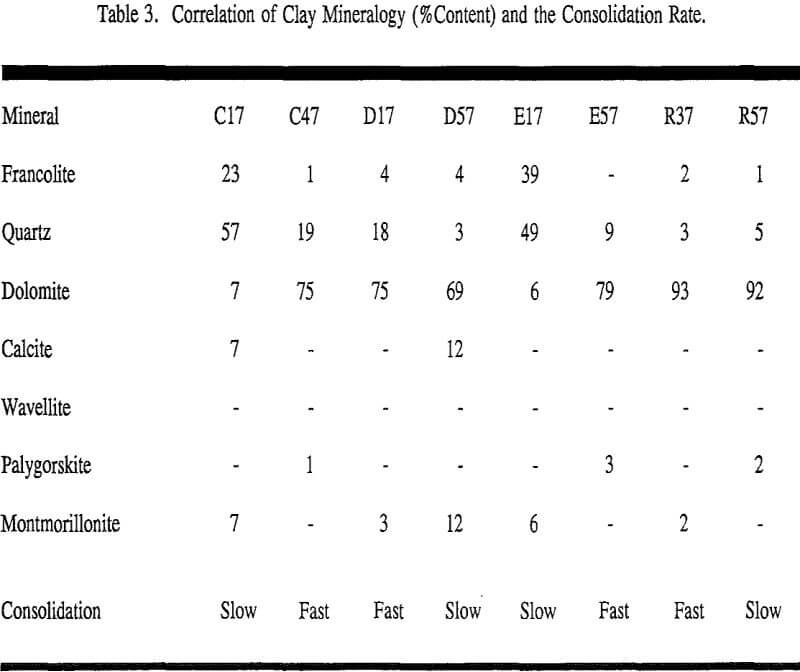

Special laboratory equipment have been developed for making the appropriate determinations including the stress-controlled slurry consolidometer, constant rate of deformation slurry consolidometer, and seepage induced consolidometer. In most of the above techniques, the testing time may range from days to several weeks. Thus, the purpose of this investigation is to examine the possibility of using bench top centrifuge to generate the above data in a shorter testing times (hours instead of weeks). The second objective is to develop a mathematical relationship that describe the consolidation behavior of the tested samples as a function of time.